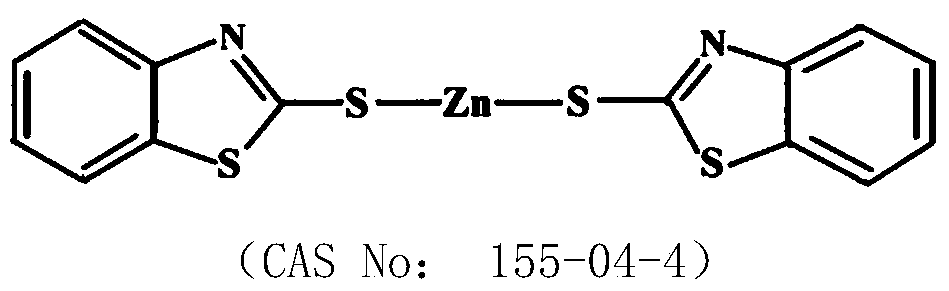

A combination of zinc 2-mercaptobenzothiazole and mitochondrial cytochrome enzyme inhibitor fungicides

A composition, a technology of zinc thiazole, applied in the agricultural field, can solve the problems of not being able to control multiple diseases at the same time, easy to produce resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

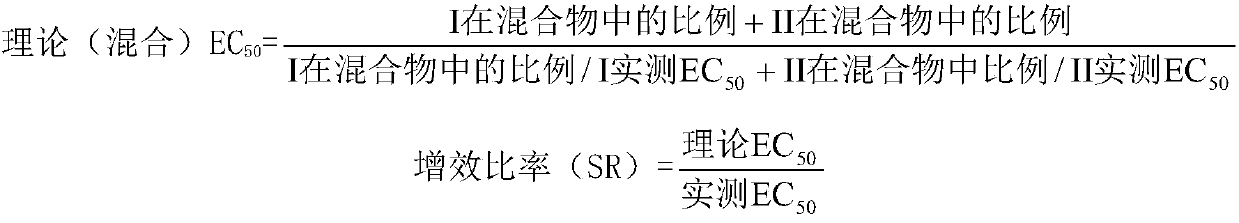

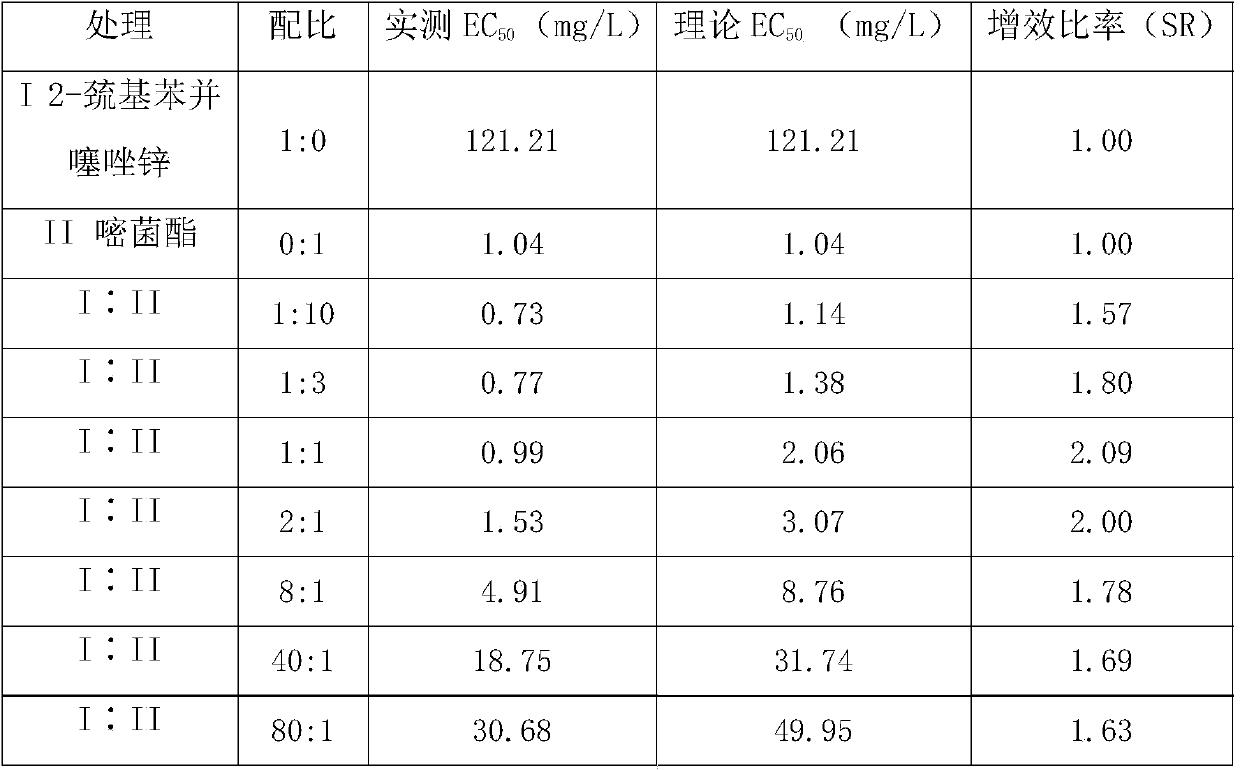

Method used

Image

Examples

Embodiment 1

[0083] 40% active compound (35.0% 2-mercaptobenzothiazole zinc and 5.0% pyraclostrobin composition), fatty alcohol polyoxyethylene ether 2.0%, maleic acid-acrylic acid homopolymer sodium salt 3.0%, yellow Raw gum 0.05%, magnesium aluminum silicate 0.6%, sodium starch octenyl succinate 1.0%, glycerol 2.0%, phenyl salicylate 0.4%, silicone defoamer 0.1%, deionized water to 100 %, put it into a high-shear homogeneous emulsifier and shear it at high speed for 20 minutes, then transfer it to a sand mill, and circulate sand mill for 1-3 times to obtain a 40% content active compound suspending agent.

Embodiment 2

[0085] 30% active compound (20.0% 2-mercaptobenzothiazole zinc and 10.0% azoxystrobin combination), fatty alcohol polyoxyethylene ether sulfate 1.0%, phenolsulfonic acid condensate sodium salt 1.0%, polymer polycarboxylate Salt 2.0%, sodium starch octenyl succinate 2.0%, glycerol 2.0%, silicone defoamer 0.1%, Cathone 0.2%, deionized water to 100%, put into high-shear homogeneous emulsification High-speed shearing in the machine for 25 minutes, then pumped into a sand mill for 90 minutes of sand grinding, and filtered to obtain a 35% active compound suspension.

[0086] 2. Microcapsule suspension

Embodiment 3

[0088] 25% active compound (10.0% 2-mercaptobenzothiazole zinc and 15.0% trifloxystrobin composition) microcapsule suspension preparation method: 10.0% 2-mercaptobenzothiazole zinc, 15.0% trifloxystrobin, alkylnaphthalene Sulfonate 1.0%, acyl glutamate 2.0%, silicone defoamer 0.1%, polyphenyl polymethylene polyisocyanate PAPI 3% and diphenylmethane diisocyanate MDI 2%, gum arabic (5% 10% aqueous solution and 40.46% deionized water are fully mixed, and then put into a sand mill for sand grinding until the D90 particle size is 3-5 microns. Start stirring (maintain 700 rpm), then raise the temperature of the sand-milled suspension to 60°C, and slowly add 0.04% triethanolamine at the same time to maintain a stable solidification temperature of the capsule wall material for 8 hours, then add fatty alcohol polyoxyethylene ether Sulfate 1.0%, sodium methylnaphthalenesulfonate formaldehyde condensate 1.0%, urea 2.0%, glycerol 2.0%, aluminum magnesium silicate (2%) aqueous solution 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com