Electric cooker temperature control assembly, electric cooker with same and temperature control method

A rice cooker and assembly technology, applied in the field of rice cooker and temperature control, and rice cooker temperature control assembly, can solve the problems of multiple human resources, large temperature tolerance, fragile magnetic steel temperature limiter, etc., and achieve The effect of high safety factor and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

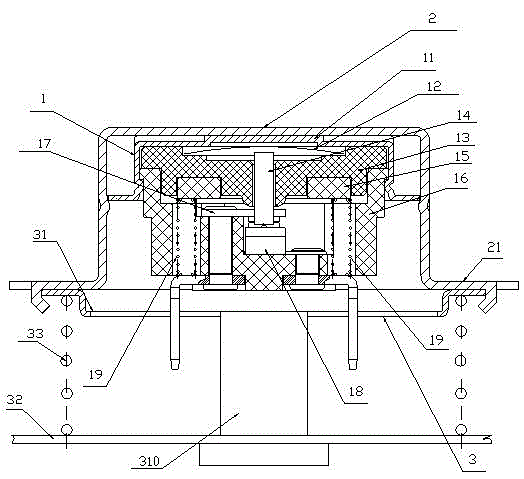

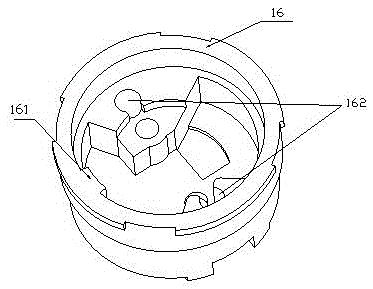

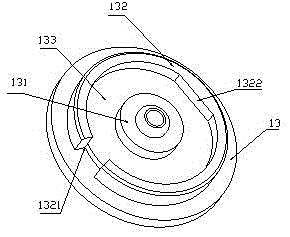

[0027] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

[0028] like Figures 1 to 6, the rice cooker temperature control assembly 10 of the present invention includes a power-off reset snap-type thermostat 1 and a heat-conducting cover 2, the opening of the heat-conducting cover 2 extends outwards with a skirt 21, and the power-off reset snap-type The thermostat 1 is fixed in the heat conduction cover 2 , and the temperature sensing surface of the snap-off thermostat 1 is closely attached to the inner top surface of the heat conduction cover 2 , and the lower part of the heat conduction cover 2 is provided with an elastic member 3 . The power-off reset jump type thermostat con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com