Haemorrhoids loop ligature device

A technology for ligation and hemorrhoids, applied in surgical cutting instruments, medical science, surgery, etc., can solve the problems that the suction effect is not as good as that of electric suction ligation, does not display negative pressure value, and is inconvenient to use, etc., and achieves a simple and reliable structure , unique concept, easy to disassemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

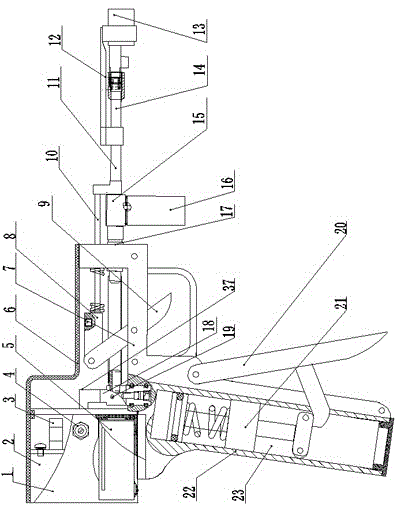

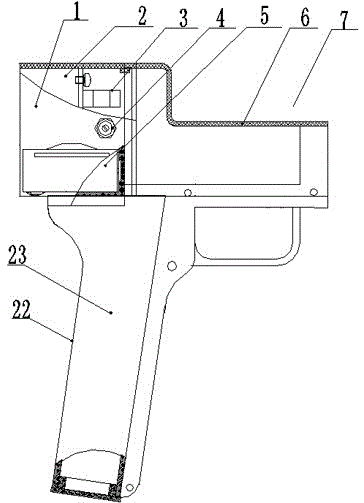

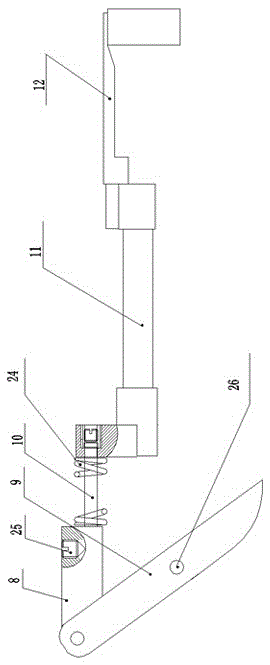

[0020] In order to describe the present invention in detail, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0021] From Figure 1-Figure 7 It can be seen from the figure that the present invention includes a main body system, a ligation operating system, and a negative pressure suction operating system. The main system includes a ligation device main body 7, an upper cover 6, and a pressure display device 1. There is a handle 22, and an air chamber 23 is arranged in the handle 22. The pressure display device 1 is arranged above the handle 22. The pressure display device 1 is equipped with a battery box 5, a pressure sensor 2, an external power socket 4 and a switch 3, and the upper cover 6 is arranged on the upper part of the ligation device main body 7; the ligation operating system includes a pusher block 8, a trigger 9, a push rod 10, a push rod 11, and a ligation push rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com