Modularized photocatalytic device for organic waste gas treatment and method

A technology of organic waste gas and photocatalysis, which is applied in the direction of chemical instruments and methods, separation methods, auxiliary pretreatment, etc., can solve the problems of lack of pretreatment and posttreatment means, difficult disassembly of devices, and difficult replacement of components, so as to achieve favorable operation Ease of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

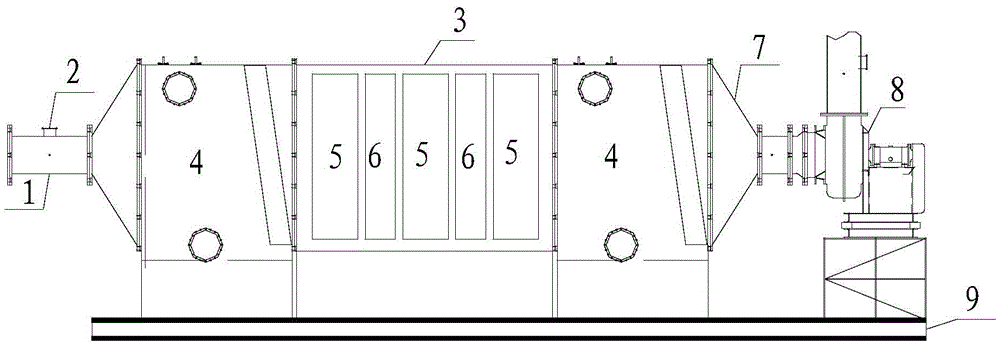

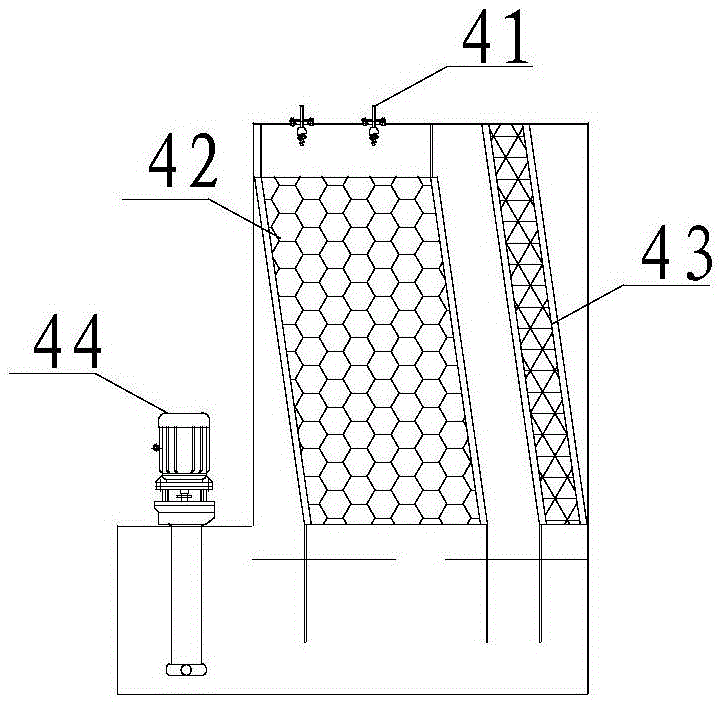

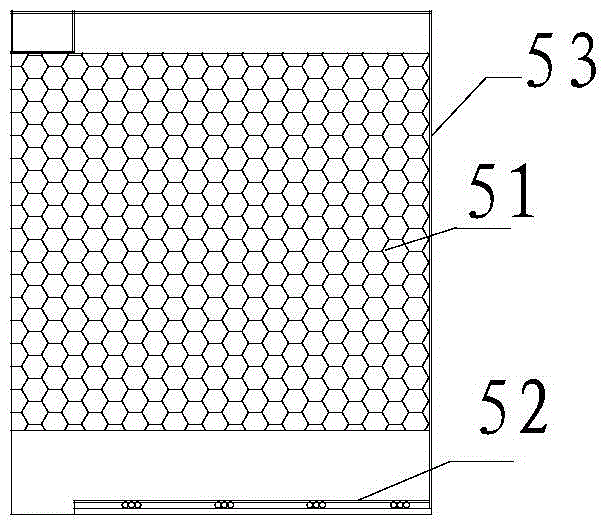

[0070] Simulate the discharge of typical industrial waste gas, prepare the waste gas whose main pollution factor is toluene, and control the flow rate of the waste gas to 1000m 3 / h, the concentration of toluene is 100mg / m 3 about. If the photocatalytic device shown in the attached figure is established, the device has a total of 3 UV lamp modules, and each module is equipped with 5 UV lamps; the UV lamp is a U-shaped lamp with a length of 810mm, a power of 150w, and a peak wavelength of 254nm. Two photocatalytic modules form the photocatalytic main body section with the ultraviolet lamp module. Water spray modules are installed in the front and back of the photocatalytic main section, and each module is equipped with 3 nozzles at the top, with a spray flow rate of 4.5m 3 / h. The end is a fan module, and the air volume of the fan is 1000m 3 / h, the maximum wind pressure is 1500Pa, equipped with a frequency converter to adjust the flow.

[0071] When the device is running,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com