Light catalytic treatment reactor for organic waste water

A technology of organic wastewater and photocatalysis, applied in the direction of light water/sewage treatment, etc., can solve the problems of weak photocatalytic treatment capacity, damaged structure, and high equipment requirements, so as to improve the photocatalytic treatment efficiency, improve the treatment efficiency, and the device structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

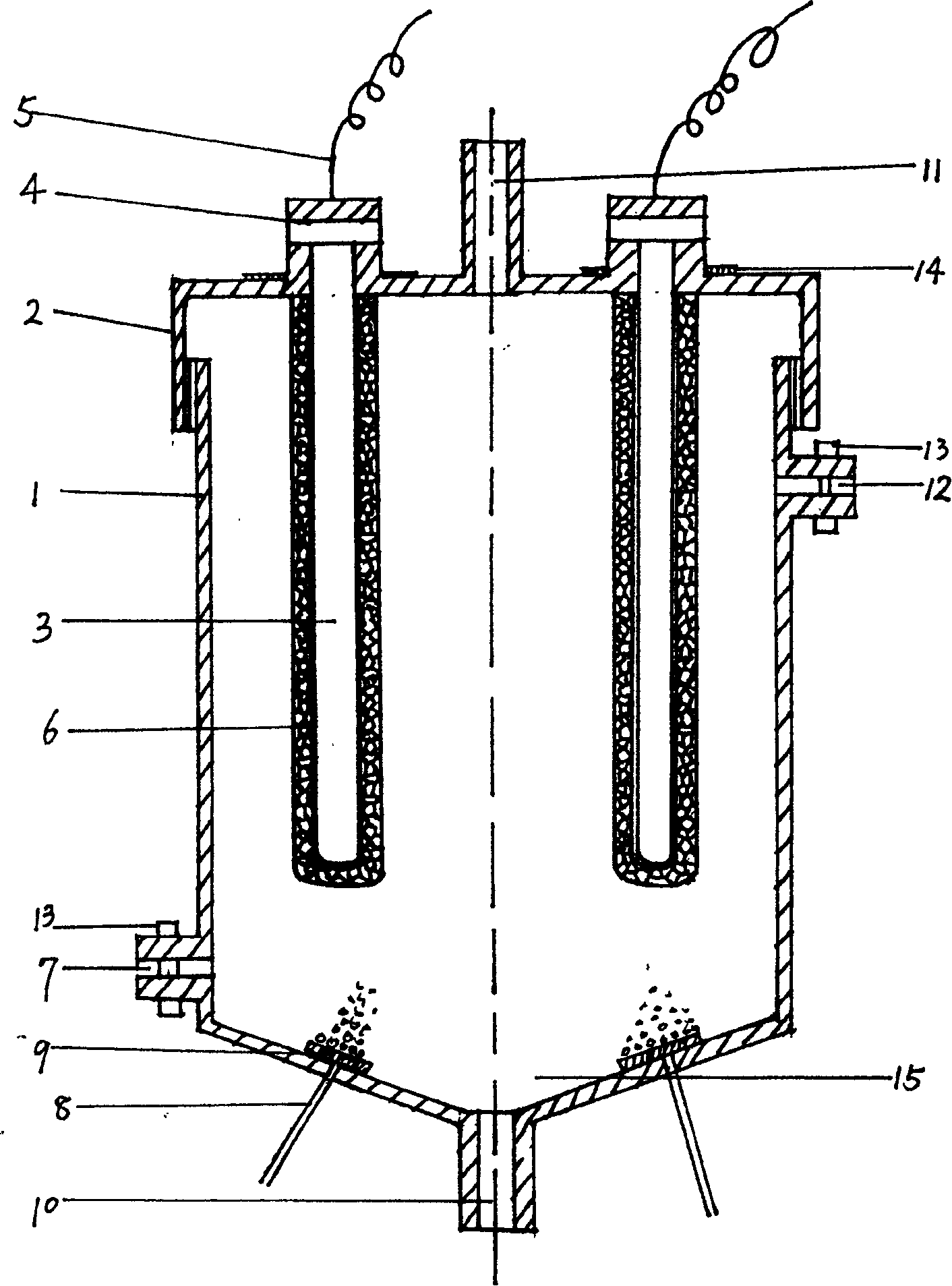

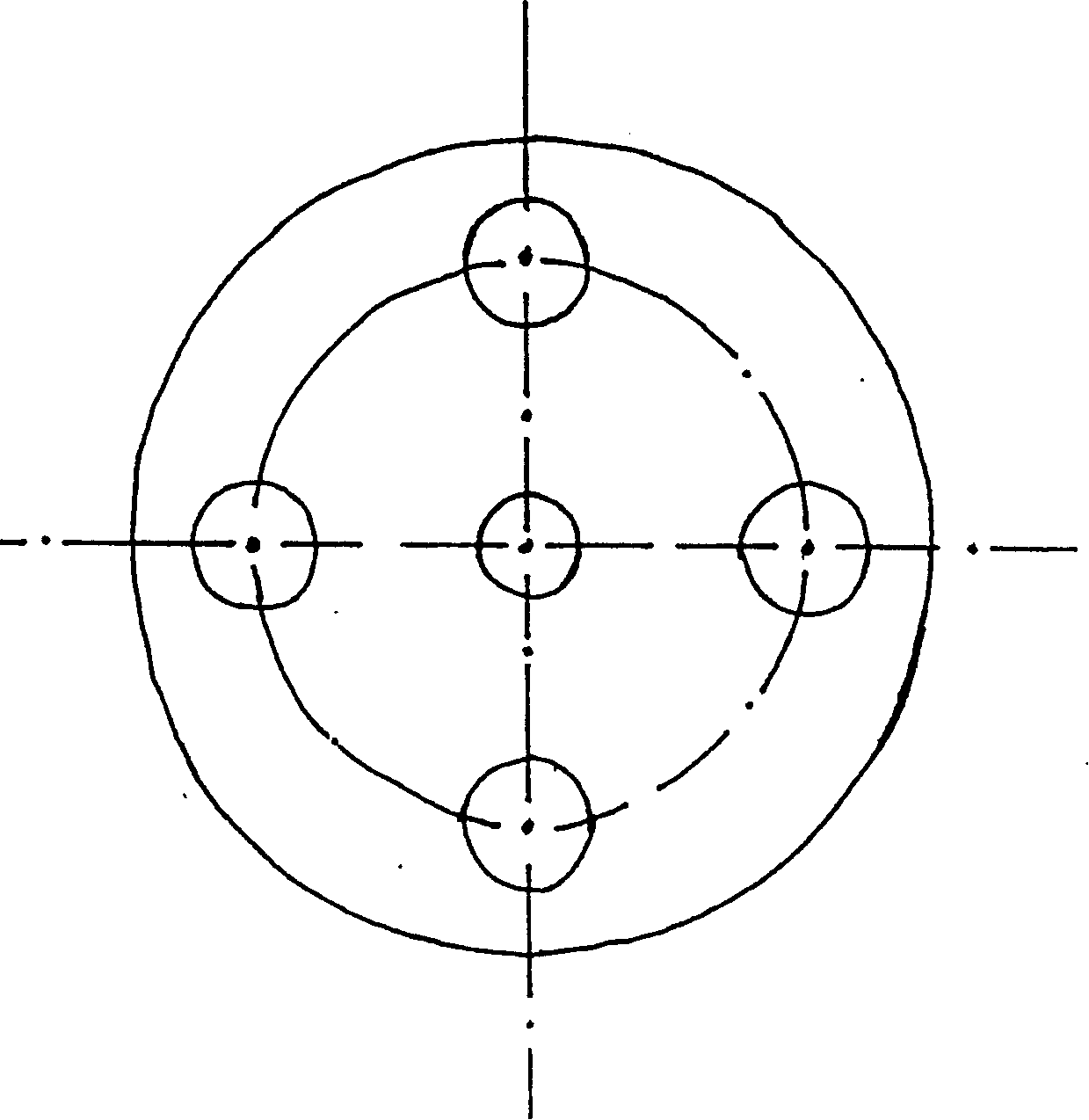

[0025] figure 1 , 2 The schematic structure of is a specific implementation structure of the photocatalytic reactor device of the present invention. The shell 1 of the reactor is made of stainless steel. The lower part of the side wall of the shell is provided with a water inlet 7, and the upper part is provided with a water outlet 12. Both the water inlet 7 and the water outlet 12 are equipped with a regulating valve 13. There are 4 Each photocatalytic assembly is composed of an ultraviolet lamp tube 3 and a photocatalyst package 6. The ultraviolet lamp tube is a high-pressure mercury lamp that can directly contact with water, and the lamp cap 4 of the light tube is fixed on a heat-resistant On the PVC plate 14, the PVC plate is fixed on the top cover 2 of the reactor, and the photocatalyst suite 6 is the carrier of the grid-shaped activated carbon fiber cylinder, and the photocatalyst TiO is attached on the surface of the activated carbon fiber and in the pores thereof. 2 ...

Embodiment 2

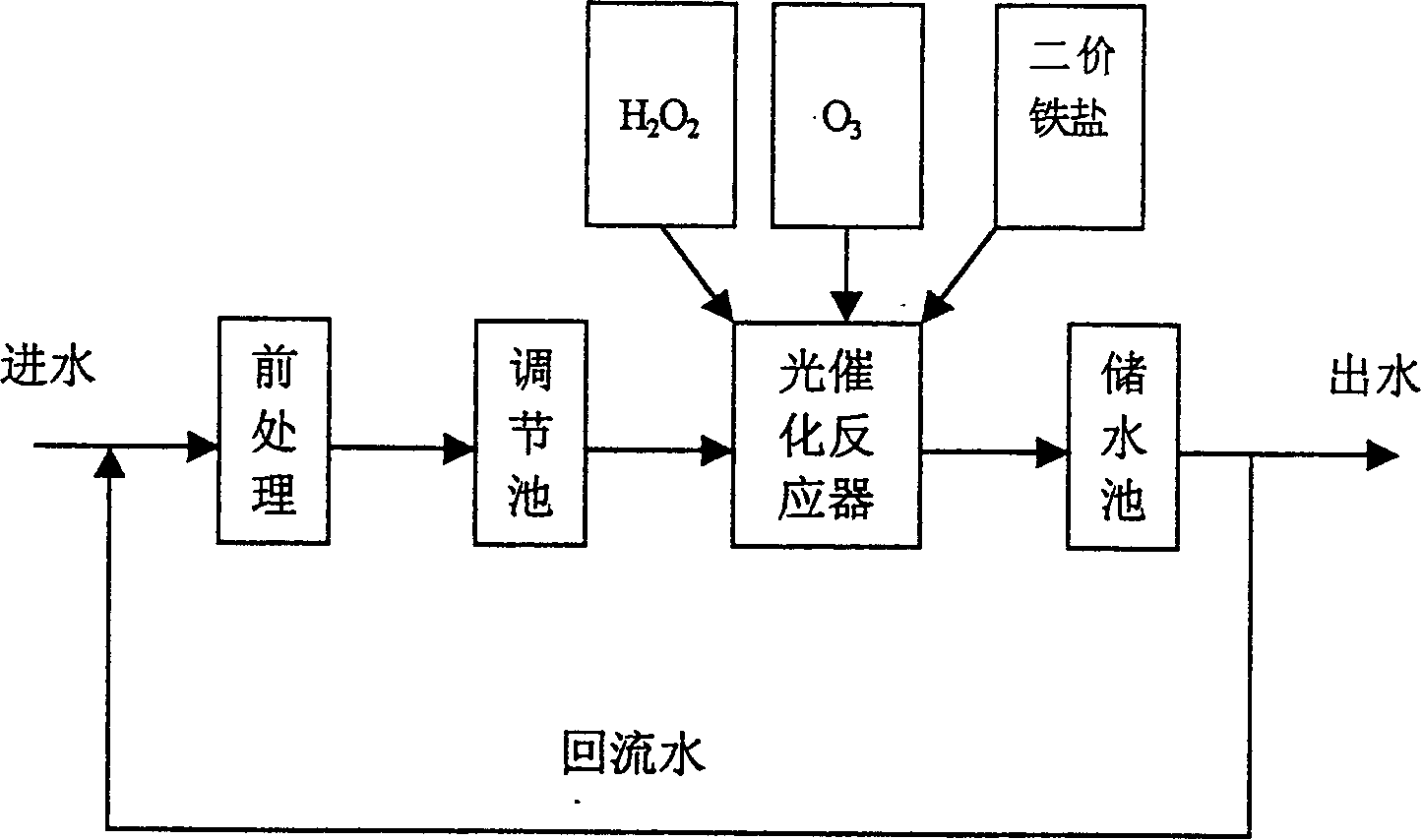

[0027] This example is the photocatalytic treatment of industrial wastewater from an organic additive factory. Its process is as image 3 shown. After the industrial wastewater is pre-treated by flocculation and sedimentation and then adjusted by the adjustment tank, the effluent COD is 2548.5mg / L, dinitrophenol is 128.7mg / L, aniline is 187.6 / L, and sulfide is 48.2mg / L. The waste water is passed into the photocatalytic reactor device, the flow rate is controlled to be 50L / hour, and 25mg / L of ozone is injected at the same time, and H 2 o 2 When the concentration reaches 0.6ml / L, add FeSO 4 When the concentration reaches 0.0045mol / L, the wastewater from the photocatalytic reactor device enters the storage tank for post-treatment, the wastewater reflux ratio is 100%, the hydraulic retention time is 6 hours, and the water quality entering the storage tank tends to be stable after 24 hours . The COD removal rate of the whole photocatalytic treatment process is 98.4%, the remov...

Embodiment 3

[0029] This example is a photocatalytic treatment of mixed wastewater from a dye factory. After the industrial wastewater is pre-treated by flocculation and sedimentation and then adjusted by the adjustment tank, the effluent COD is 3879.4mg / L, dinitrophenol is 312.1mg / L, aniline is 84.5 / L, chlorobenzene is 65.8mg / L, and sulfide is 21.5 mg / L. The waste water is treated by two-stage photocatalytic reactors, first passed into the first photocatalytic reactor device, the flow rate is controlled at 50L / hour, and 30mg / L of ozone is injected at the same time, and H 2 o 2 When the concentration reaches 0.9ml / L, add FeSO 4 When the concentration reaches 0.005mol / L, the wastewater from the photocatalytic reactor device enters the first storage tank for post-treatment, and the supernatant in it flows into the second photocatalytic reactor device, and the COD of the supernatant is 978.7 ~1235.1mg / L, flush into 20mg / L of ozone, add H 2 o 2 When the concentration reaches 0.3ml / L, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com