LED light splitting method

A spectroscopic and spectral technology, applied in the field of LED spectrometry, can solve the problems of different colors, the spectroscopic method cannot meet the requirements, and the difference of luminous color, etc., and achieve the effect of obvious sorting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

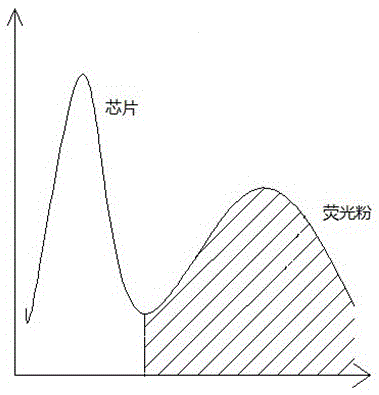

[0023] A kind of LED spectroscopic method, comprises the following steps:

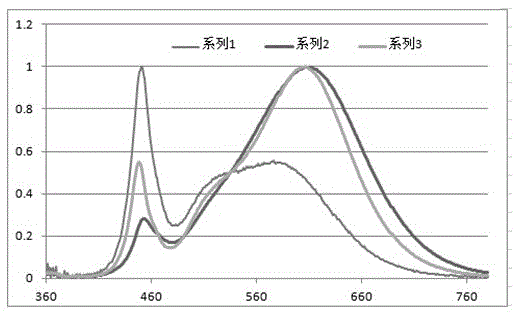

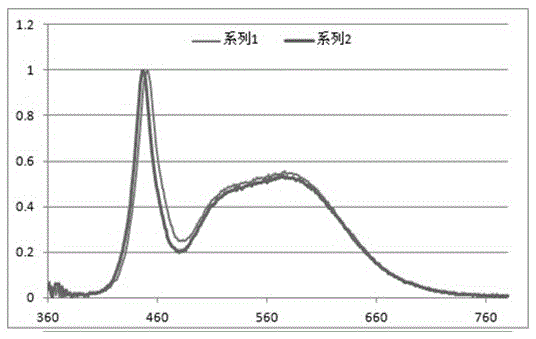

[0024] (1) Screening: Export the spectral diagram of each LED, and then compare it with the standard spectral diagram. If the similarity meets a preset requirement (such as greater than the preset value of 98%), it is judged as a first-class product. If the similarity meets another preset requirement (such as within the preset range of 96%-98%), it is judged as another grade of product, and the standard spectrum is pre-imported into the spectrometer. At this time, the consistency of parameters such as color temperature and luminous color is determined through the spectrogram.

[0025] Further, step (1) specifically includes: preliminary screening: screening LEDs with the same color temperature according to the X / Y value on the CIE1931 chromaticity diagram; screening: exporting the spectral diagram of each LED with the same color temperature, and then comparing with the standard spectral diagram In com...

Embodiment 2

[0033] A kind of LED spectroscopic method, comprises the following steps:

[0034] (1) Screening: Export the spectral diagram of each LED, and then compare it with the standard spectral diagram. If the similarity meets a preset requirement (such as greater than the preset value of 98%), it is judged as a first-class product. If the similarity meets another preset requirement (such as within the preset range of 96%-98%), it is judged as another grade of product, and the standard spectrum is pre-imported into the spectrometer. At this time, the consistency of parameters such as color temperature and luminous color is determined through the spectrogram.

[0035] Further, step (1) specifically includes: preliminary screening: screening LEDs with the same color temperature according to the X / Y value on the CIE1931 chromaticity diagram; screening: exporting the spectral diagram of each LED with the same color temperature, and then comparing with the standard spectral diagram In com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com