Motorcycle steam cylinder head pressing tool

A technology for cylinder heads and motorcycles, applied in the field of tooling fixtures, can solve the problems of high labor intensity, low clamping efficiency, shaking and displacement of motorcycle engine cylinder heads, etc., and achieves improved finishing quality, good fixing effect, and reduced labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

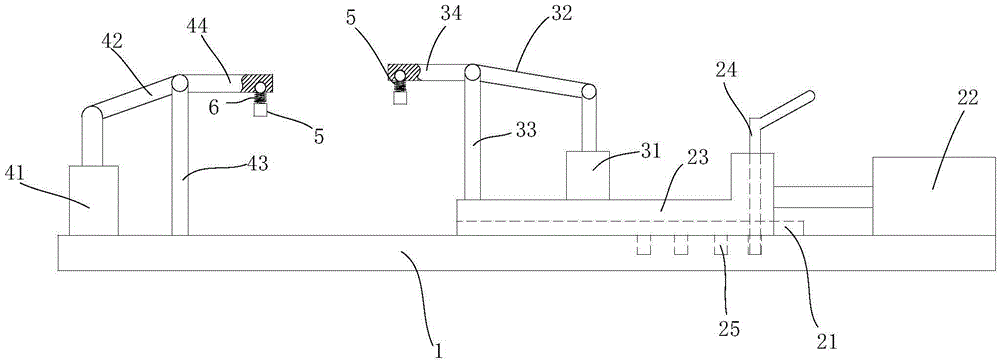

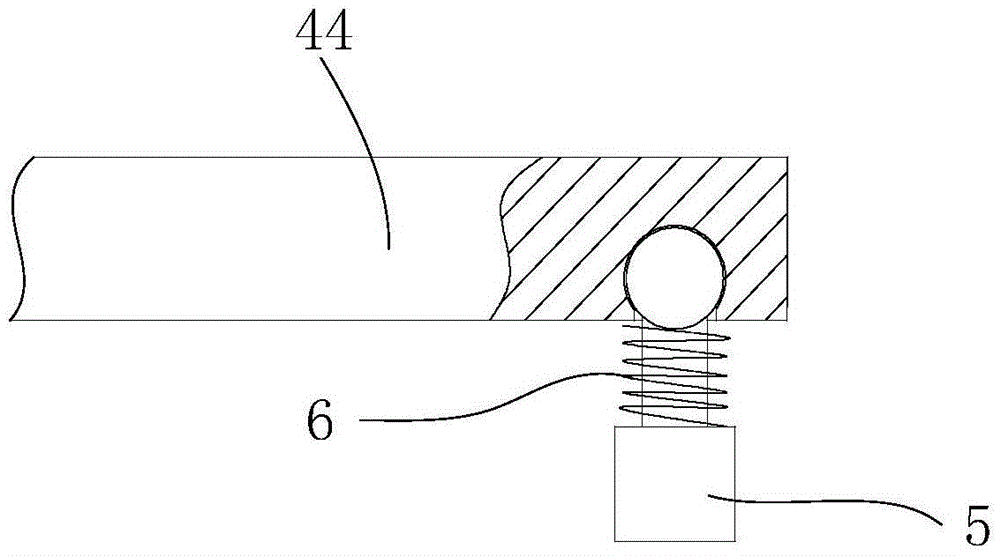

[0033] like figure 1 and figure 2 As shown, a motorcycle cylinder head pressing tool includes a support base 1, a fixed pressing assembly and a moving pressing assembly, the fixed pressing assembly is fixedly installed on the supporting base 1, and the moving pressing assembly slides The module is installed on the support base 1, and is connected with a horizontal pushing mechanism 23, which can make the moving pressing assembly close to or away from the fixed pressing assembly, and both the moving pressing assembly and the fixed pressing assembly are installed There is a pressing head 5, the lower end surface of the pressing head 5 is a horizontal plane, and the upper end of the pressing head 5 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com