Feeding machining mechanism of numerical control cutter grinding machine

A processing mechanism and tool grinding machine technology, which is applied in the direction of grinding machine parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting normal feeding, motor burnout, easy damage, etc., to meet the needs of production inspection, Reduce the probability of burning out, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

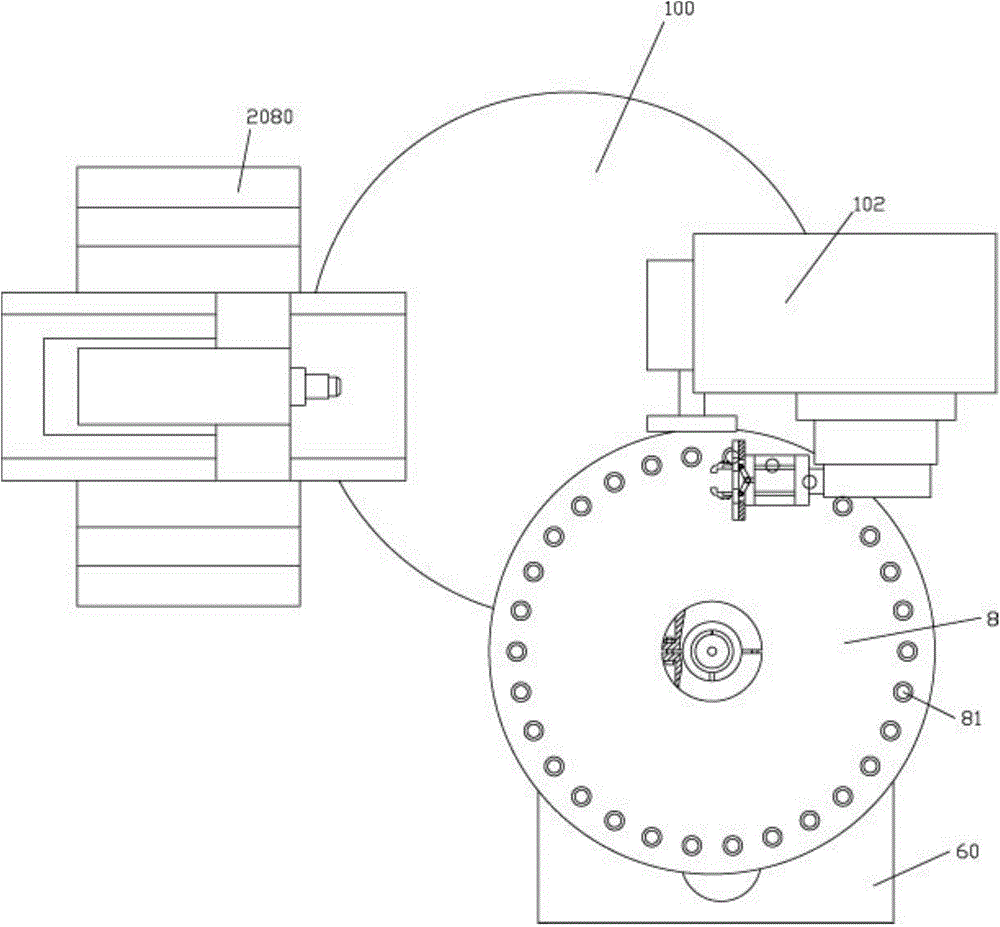

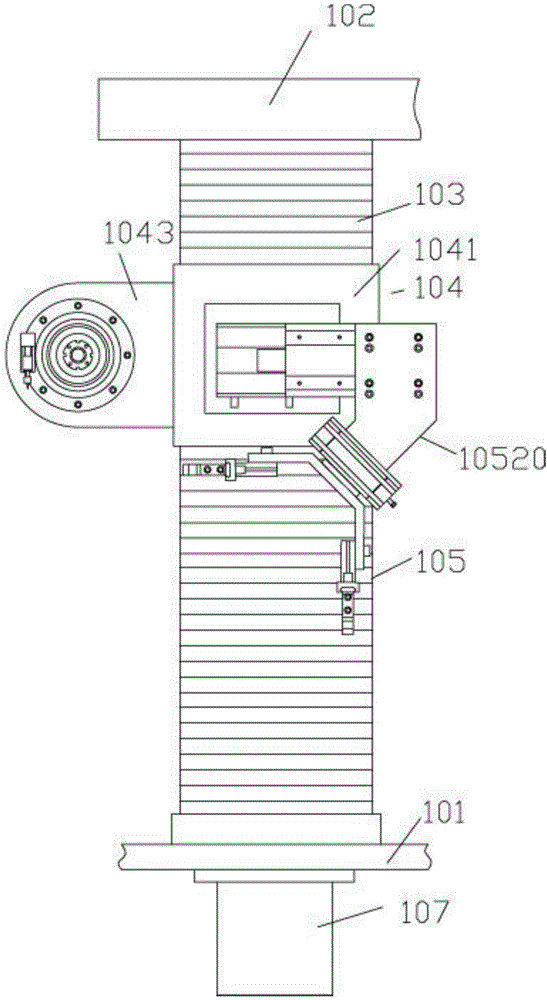

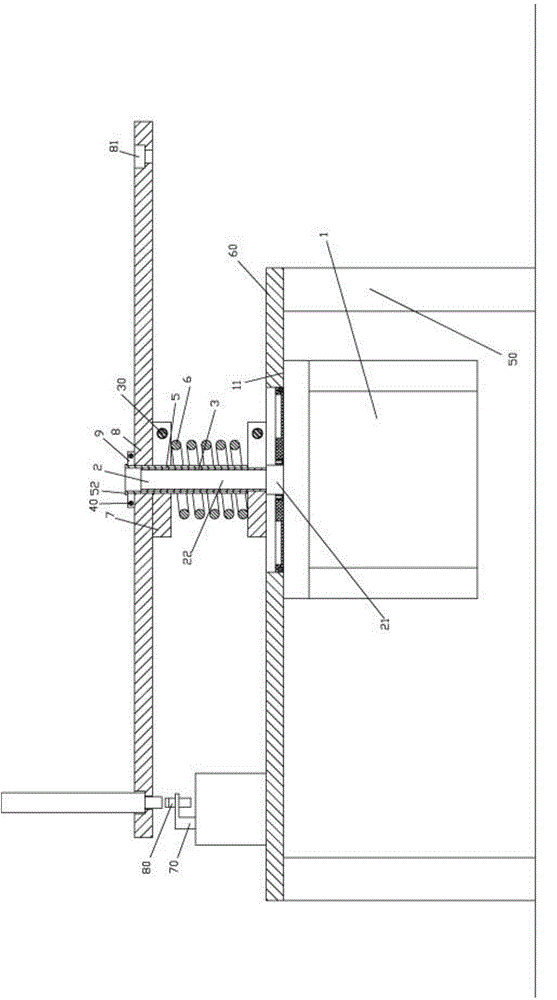

[0046] Examples, see e.g. Figures 1 to 4 As shown, a feeding processing mechanism of a CNC tool grinder includes a main frame on which a main platen 100 is fixed, a grinding wheel feeding device, a feeding turntable device and a tool rotating spindle mechanism are all fixed on the main frame, and the grinding wheel feeding The device, the feeding turntable device and the tool rotating spindle mechanism are arranged around the main platen 100. The structure of the grinding wheel feeding device is to include a lower support plate 101 and an upper support plate 102, and the lower support plate 101 and the upper support plate 102 are fixed on the On the frame, the upper end of the upper corrugated sleeve 103 is fixedly connected to the lower plane of the upper supporting plate 102, and the lower end is fixedly connected to the upper plane of the grinding wheel spindle connecting block 104, and the upper end of the lower corrugated sleeve 105 is fixed on the lower surface of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com