Climbing machine vehicle

A technology of robot car and car body, applied in the field of climbing robot car, can solve the problems of small application limitations, achieve the effect of improving safety, increasing distance, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

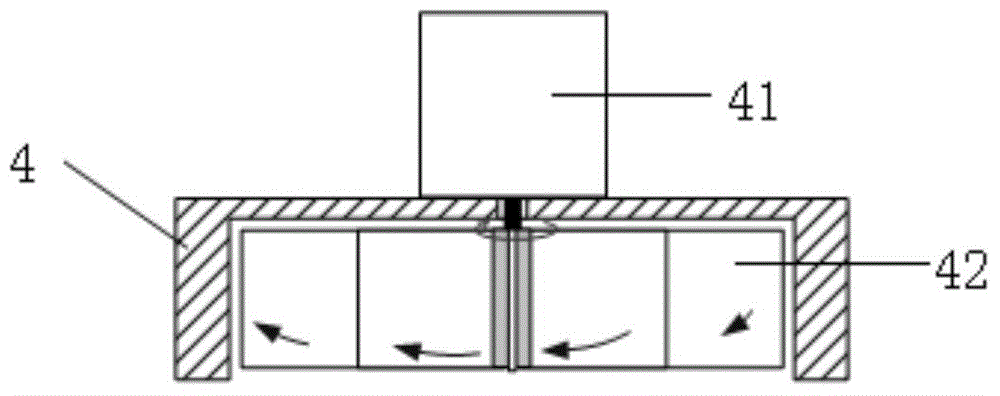

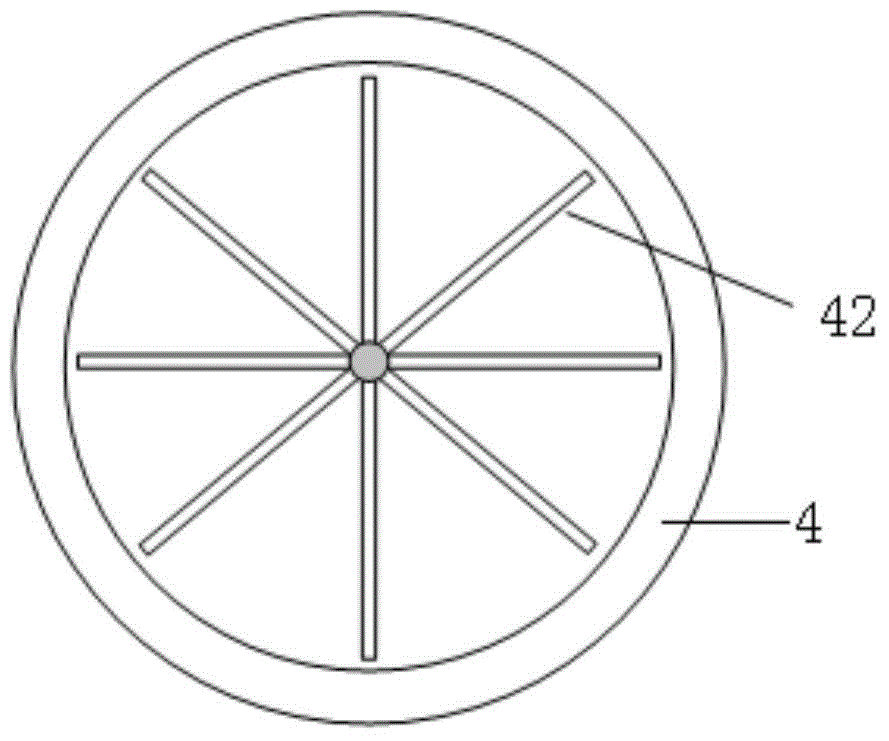

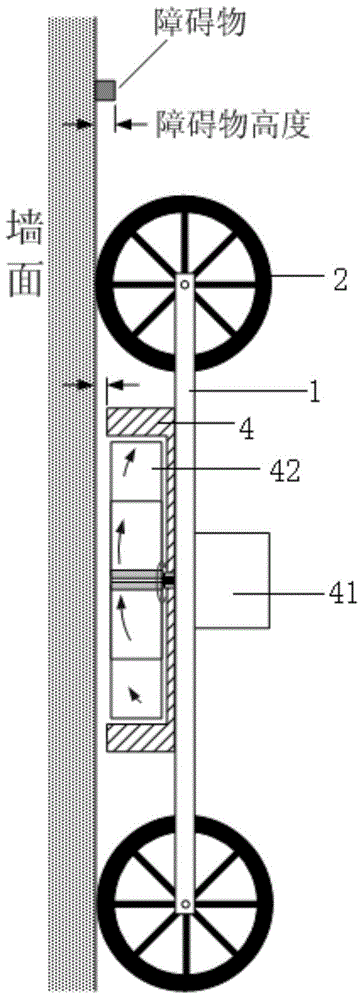

[0048] refer to Figure 1a-1b as well as Figure 5 , a climbing robot vehicle, including a car body 1, the front and rear ends of the car body 1 are installed with wheels 2, and one end of the car body 1 facing the wall 3 is connected and fixed with an adsorption mechanism 4, and the adsorption mechanism 4 includes a shell, There is a cavity with a circular cross section in the housing, the cavity has a closed end face and an open end face, the open end face forms an end face for absorbing the wall, and the closed end face is fixed on the end of the car body facing the wall A rotating power source 41 is installed on the end of the car body facing away from the wall, and the fan blade 42 arranged in the cavity is connected to the output shaft of the rotating power source. The closed end surface is in an airtight state, and the fan blade 42 is arranged along the The axis of the cavity is distributed in a straight line, and a flexible sealing structure 4 is arranged between the ...

Embodiment 2

[0054] When the climbing robot vehicle is crawling on the wall, the rotating power source 41 drives the fan blade 42 to rotate at a high speed. At this time, if foreign matter (such as small stones falling off the wall, etc.) enters the cavity, the foreign matter will collide violently with the fan blade, resulting in damage to the fan blade. Damage to the fan blades is likely to cause the adsorption mechanism to fail. In order to solve this technical problem, the present embodiment adopts the method of wrapping the fan blade with flexible material 5, such as Figure 6 As shown, all the other implementations are the same as in Example 1.

[0055] When a foreign matter collides with the fan blade, the flexible material can absorb the impact of the collision, thereby protecting the fan blade and ensuring that even if foreign matter enters the adsorption mechanism, the adsorption mechanism can still maintain normal working conditions, improving the climbing robot. safety perfor...

Embodiment 3

[0057] When the climbing robot car is crawling on the wall, the rotating power source drives the fan blades to rotate at high speed. At this time, if foreign matter (such as small stones falling off the wall, etc.) enters the cavity, the foreign matter will collide violently with the fan blade, resulting in damage to the fan blade. Damage to the fan blades is likely to cause the adsorption mechanism to fail. In order to solve this technical problem, the technical solution adopted in this embodiment is: use a material with good toughness and elasticity to make the fan blade, and the rest of the implementation is the same as that of Embodiment 1.

[0058] refer to Figure 7a ~ Figure 7b , Tendon rubber, silica gel, elastic steel sheets, etc. are typical materials. These materials can withstand impacts and collisions without damage, thereby ensuring that even if foreign matter enters the adsorption mechanism, the adsorption mechanism can still maintain a normal working state, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com