Bobbin smoothening machine

A tube management machine and tube management technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing manual operations on the bobbins, unable to meet the needs of different color bobbins, and achieve shortened identification distance, improve management efficiency, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

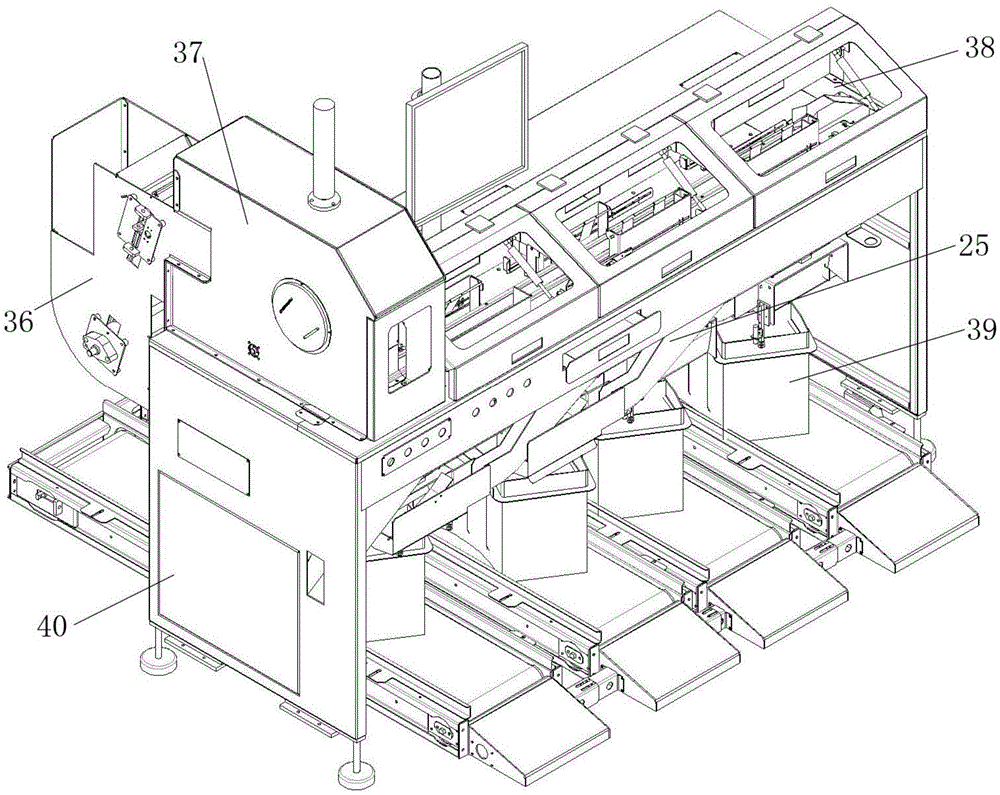

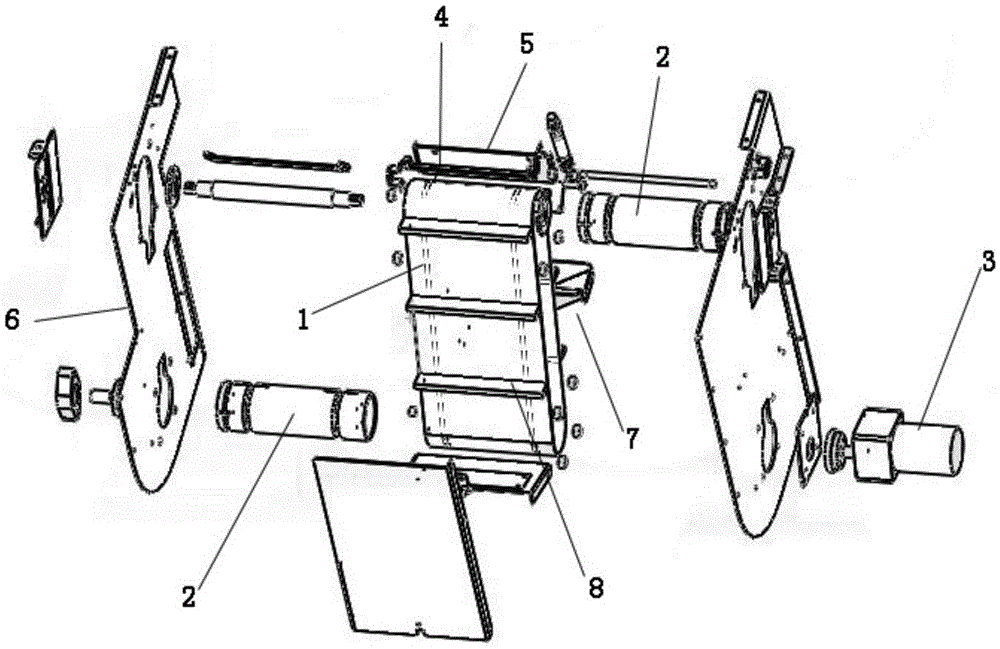

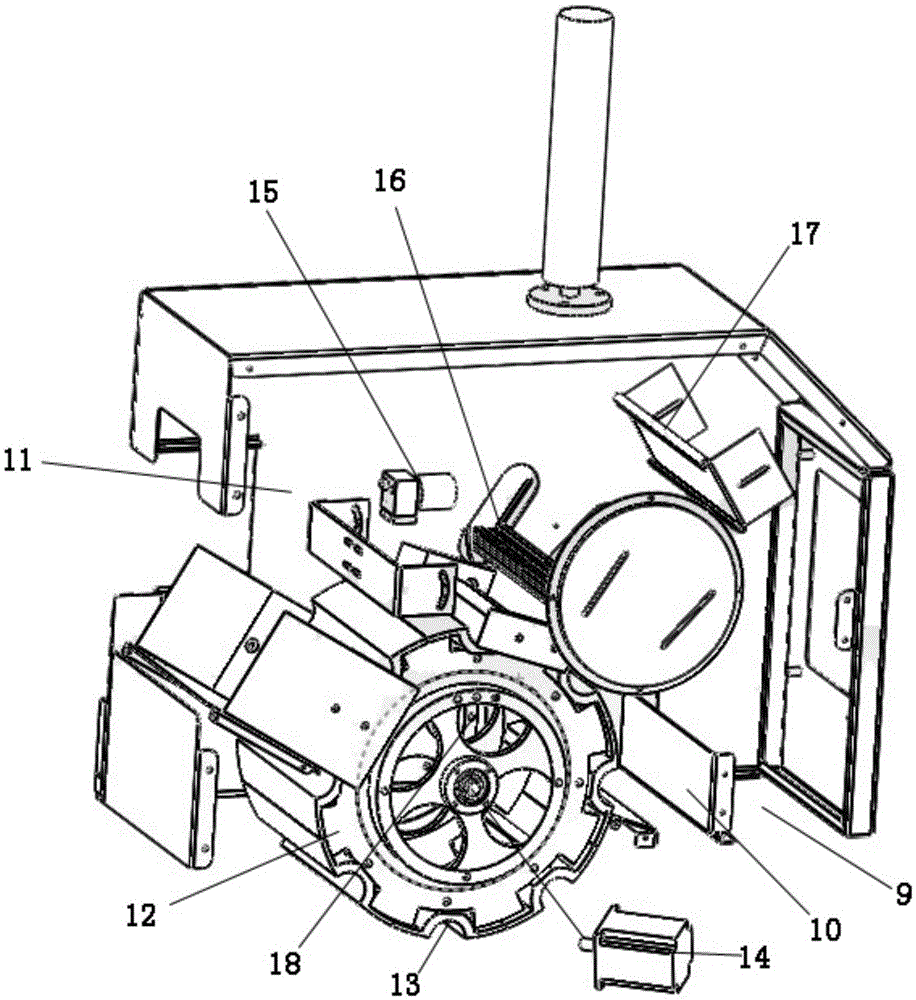

[0032] A management machine, which includes a frame 40, a PLC control system, and a tube storage device 36, a tube distribution device 37, a tube drop device 38, and a tube connection device 39 arranged on the frame. Connected with the PLC control system, the takeover device 39 is located below the drop tube device 38, and the drop tube device 38 includes a transverse conveying device 19, and the two sides of the transverse conveying device 19 are respectively provided with a spun yarn blanking slide 21 and at least one non-yarn blanking slide. 22, the spun yarn blanking chute 21 is arranged at one end close to the lateral conveying device 19, and the lateral conveying device 19 is provided with a corresponding pneumatic kicking device on the other side of the spun yarn blanking chute 21 and the non-yarn blanking chute 22. In the device 20, a position sensor 24 is provided at each slide opening of the spun yarn blanking slideway 21 and the non-yarn blanking slideway 22, and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com