Fault self-examining device of shear fork type lifting machine

A fault self-checking and lift technology, applied in the direction of lifting device, lifting frame, lifting equipment safety device, etc., can solve problems such as failure to early warning of lift failure, no automatic detection of key components, etc., and achieve the effect of avoiding manual regular maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

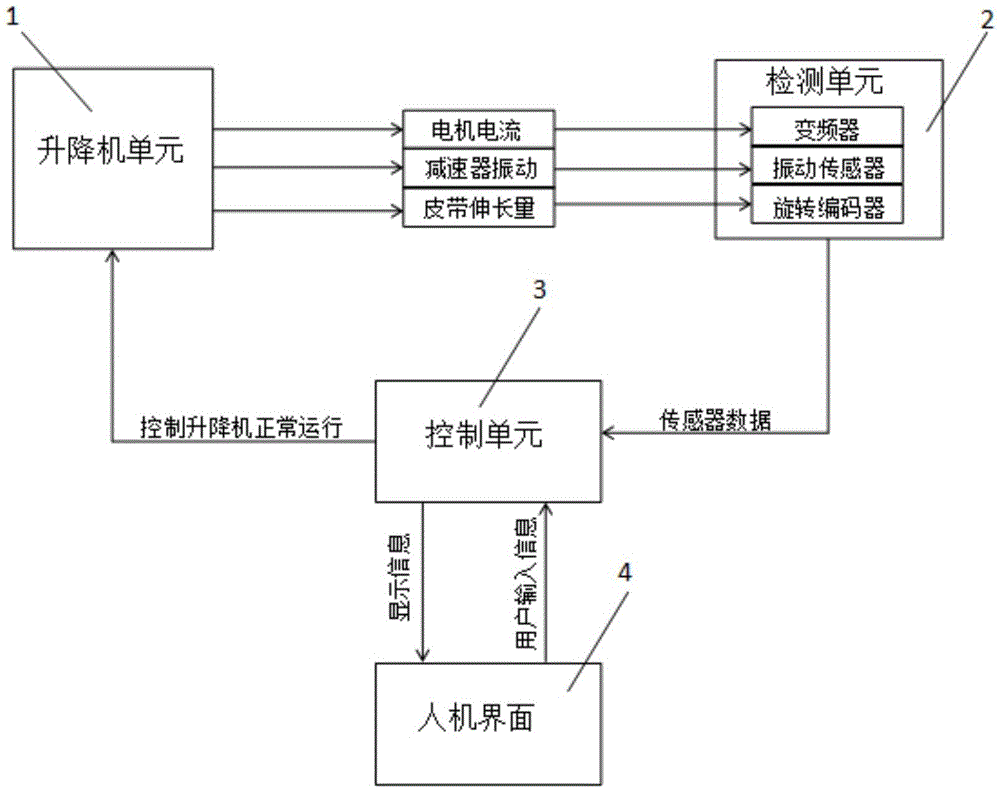

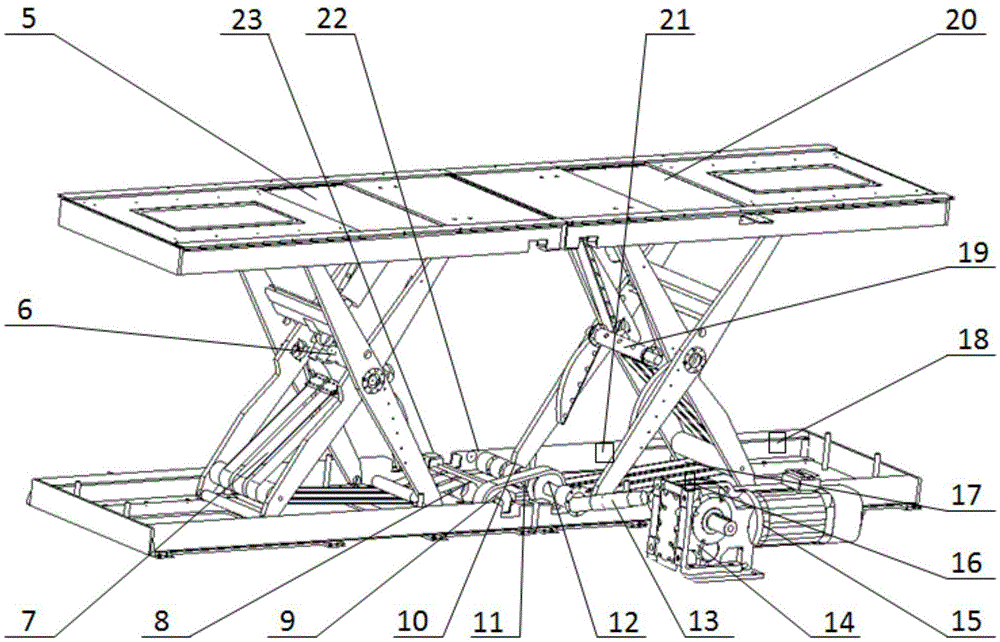

[0031] see figure 1 , the present invention provides a scissor lift with a fault self-checking device, a lift unit 1 , a detection unit 2 , a control unit 3 and a man-machine interface 4 . Lift unit 1 is exactly the scissor lift among the present invention. The detection unit 2 includes a frequency converter, a vibration sensor 16, and a rotary encoder.

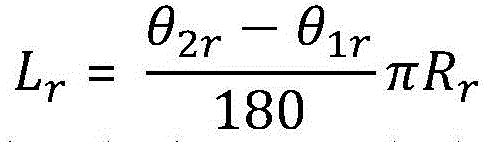

[0032] The detection unit 2 is arranged on the scissor lift, and the extension distance of the belt of the scissor lift, the vibration of the motor reducer and the operating data of the motor are automatically detected through the detection unit 2, and then through the corresponding interface of the control unit 3 Collect the detected data, and use the collected data combined with the failure rules of the scissor lift equipment components to judge the status of the components, and finally display the status ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com