Split-type mini multifunctional concrete temperature intelligent on-line monitoring system

A concrete temperature and monitoring system technology, applied in general control systems, control/regulation systems, thermometers, etc., can solve the problems affecting the accuracy of data measurement and reading, analysis and results, reducing the survival rate of temperature sensors, and inability to effectively monitor temperature changes, etc. Problems, to achieve low design and implementation costs, good current limiting protection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

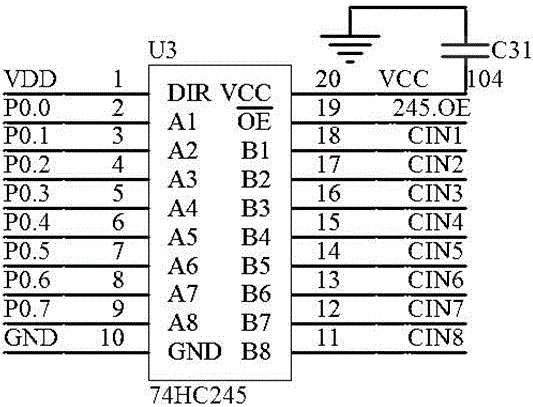

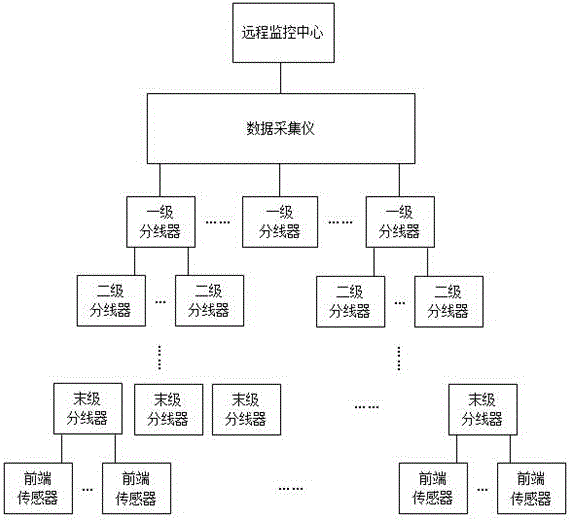

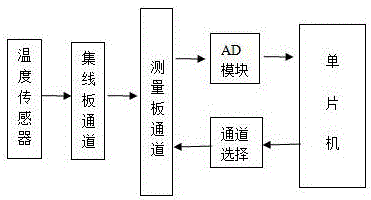

[0050] Such as figure 1 As shown, the disassembled mini multifunctional concrete temperature intelligent online monitoring system includes a remote monitoring center, a data collector, at least one splitter and several front-end sensors. The front-end sensors include a 3KΩ thermistor temperature sensor and a PT1000 platinum resistance temperature sensor. and a copper resistance temperature sensor; the data acquisition instrument communicates with the remote monitoring center through a communication network, and the sampling signal input terminals of the data acquisition instrument are respectively connected to each first-level line distributor, and each first-level line distributor is connected to multiple second-level Splitter, the final s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com