Method, system, solid-liquid conversion time point determination method and device for crystal growth

A technology for crystal growth and determination methods, applied in crystal growth, measurement devices, post-processing devices, etc., can solve problems such as the determination accuracy is limited by experience, easy to observe failure, melt sloshing, etc., to achieve fully automated growth, solution Observe failure-prone, quality-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

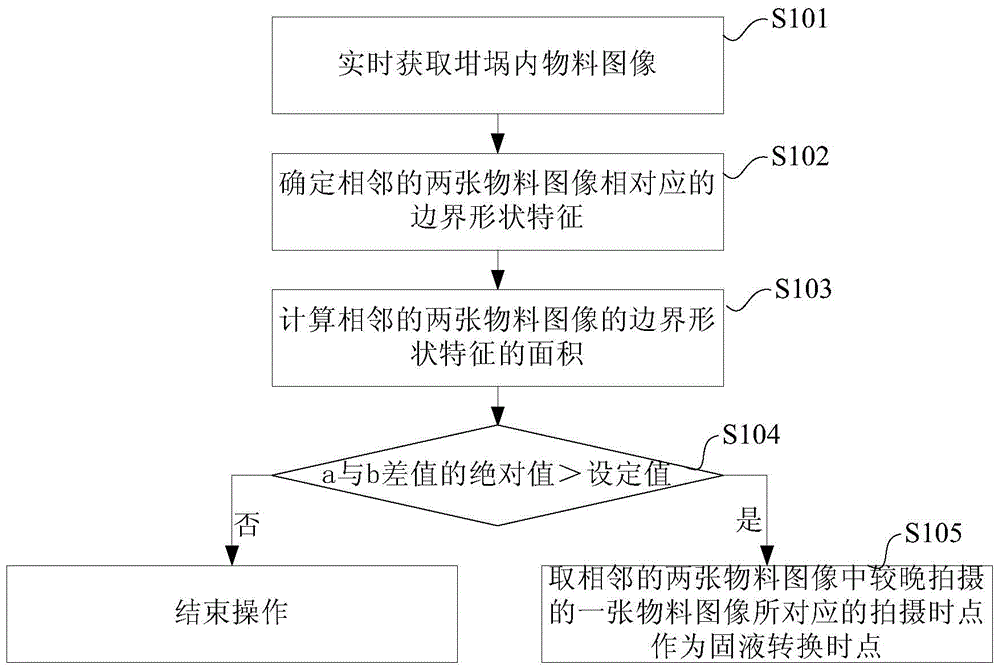

[0058] Please refer to the attached figure 2 , figure 2 The flowchart of the method for determining the solid-liquid transition time point of crystal growth provided by Embodiment 1 of the present invention is shown. The method for determining the solid-liquid transition time point of crystal growth provided in Embodiment 1 of the present invention is applicable to the heat exchange crystal growth method. The solid-liquid conversion time point refers to the time point when the solid material starts to melt or the surface of the liquid raw material starts to crystallize during the crystal growth cycle. Of course, this time point is a time point in the crystal growth cycle.

[0059] figure 2 The process shown includes:

[0060] S101. Obtain images of materials in the crucible in real time.

[0061] Step S101 is usually completed by a camera, a CCD image sensor or a video recorder. Depending on the detection accuracy, the accuracy of the corresponding acquired material i...

Embodiment 2

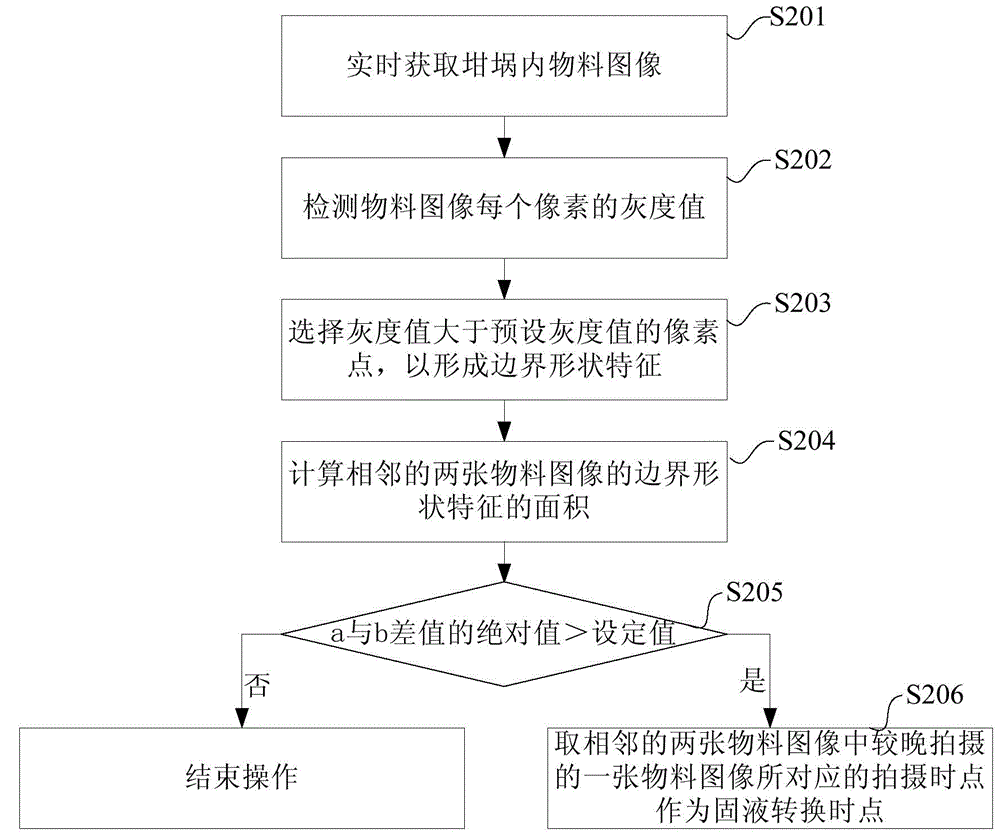

[0074] Please refer to the attached image 3 , image 3 The flowchart of the method for determining the solid-liquid transition time point of crystal growth provided by Embodiment 2 of the present invention is shown.

[0075] image 3 In the flow shown, determining the boundary shape features corresponding to two adjacent material images includes the following steps:

[0076] S202. Detect the gray value of each pixel of the material image.

[0077] In step S202, the gray value of each pixel is calculated by detecting the gray value of each pixel in the material image.

[0078] S203. Select pixels whose grayscale values are greater than a preset grayscale value to form boundary shape features.

[0079] During the crystal growth process, the temperature in the furnace body is very high. When the material in the furnace starts to melt, the boundary of the block raw material gradually shrinks. The temperature of the block raw material itself is lower than the temperature of ...

Embodiment 3

[0083] Please refer to the attached Figure 4 , Figure 4 The flow chart of the method for determining the solid-liquid transition time point of crystal growth provided by Embodiment 3 of the present invention is shown.

[0084] Figure 4 In the flow shown, determining the boundary shape features corresponding to two adjacent material images includes the following steps:

[0085] S302. Detect the gray value of each pixel in the material image.

[0086] In step S302, the gray value of each pixel is calculated by detecting the gray value of each pixel in the material image.

[0087] S303. Calculate the difference between the gray values of all two adjacent pixels.

[0088] The difference between the gray values of all two adjacent pixels is calculated according to the gray value of each pixel acquired in step S302. During the process of crystal growth, the temperature in the furnace body is very high. When the materials in the furnace start to melt, the boundaries of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap