A pull-type filling door for railway tank cars

A lifting type and tank car technology, which is applied in the direction of railway car body parts, door leaves, door devices, etc., can solve the problems of low ventilation efficiency, no ventilation function, explosion and other problems in the operation room, achieve beautiful appearance, save manpower, and closed flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to solve the problem of potential danger existing in the filling door of the existing railway tank car, the present invention designs a lifting type filling door for the railway tank car.

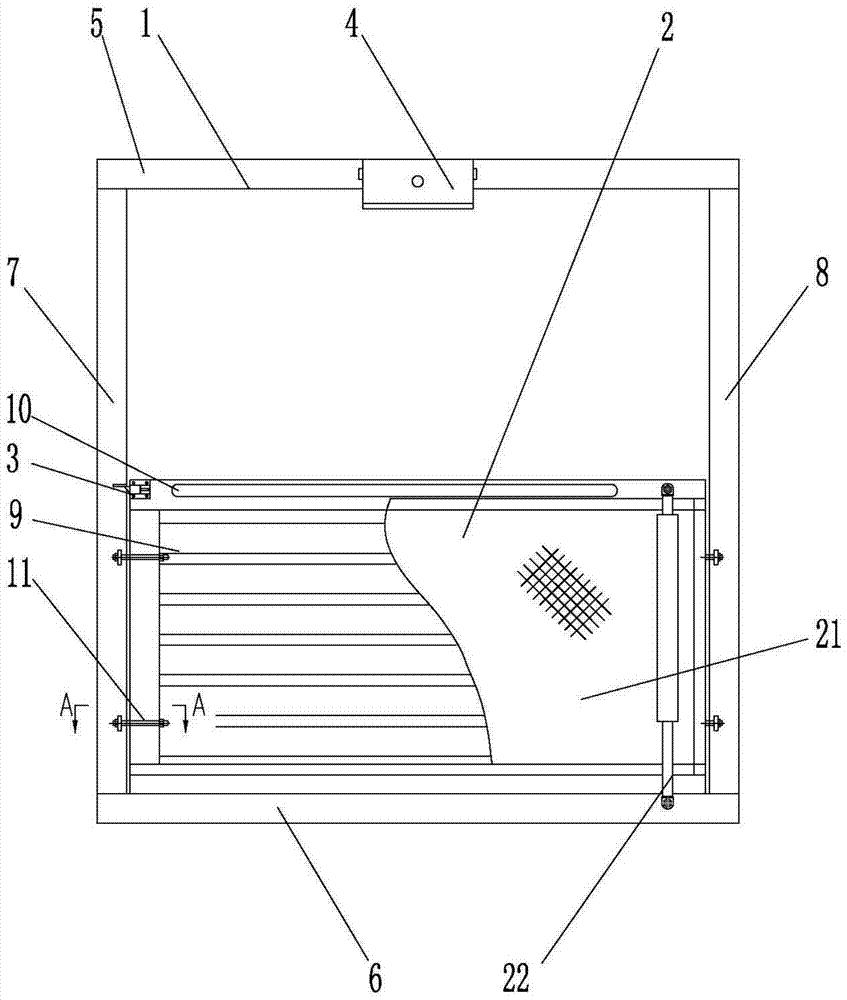

[0032] Such as figure 1 As shown, the filling door includes a fixed frame 1, a door body assembly 2, a latch 3 and a locking mechanism 4;

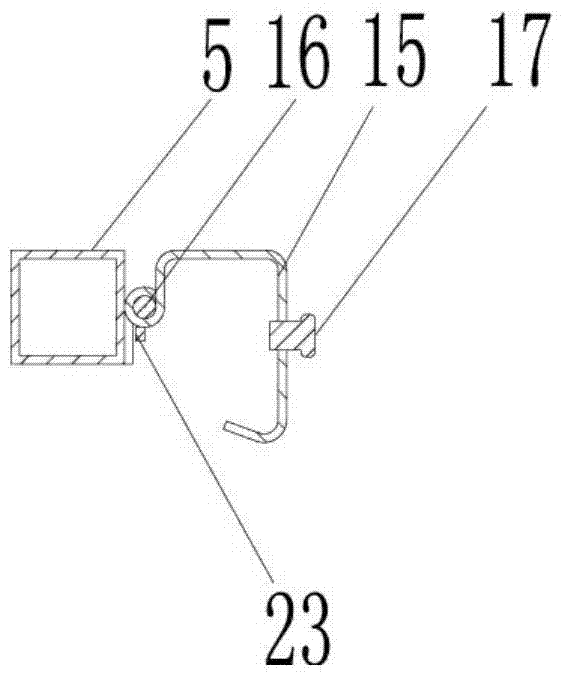

[0033] Among them, the fixed frame 1 includes an upper frame 5, a lower frame 6, a left rail 7, and a right rail 8 welded in sequence, all of which are made of rectangular cold-formed hollow steel;

[0034] The door assembly 2 includes a dodge door 9, a U-shaped handle 10 and a sliding assembly 11; the U-shaped handle 10 is installed on the top of the dodge door 9; the sliding assembly 11 is provided with at least two groups and is installed on both sides of the dodge door 9, Provide for the dodge door 9 to move up and down;

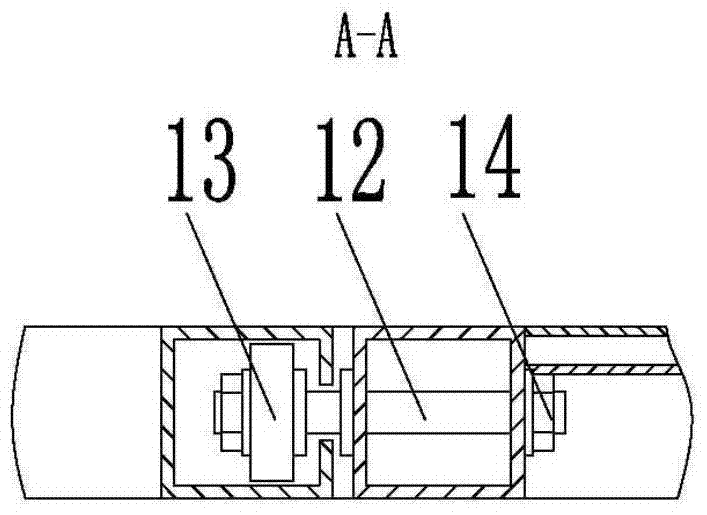

[0035] Specifically, the sliding assembly 11 includes a fixed shaft 12, a bearing 13 and a lock nut 14; the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com