Uniform load sliding bearing

A technology of sliding bearings and bearing pads, which is applied in the field of load-balanced sliding bearings, can solve problems affecting bearing capacity, temperature rise of thrust pads, jamming of pad bodies and pad sleeves, etc., so as to improve safety and reliability, reduce Oil film pressure and tile temperature, the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

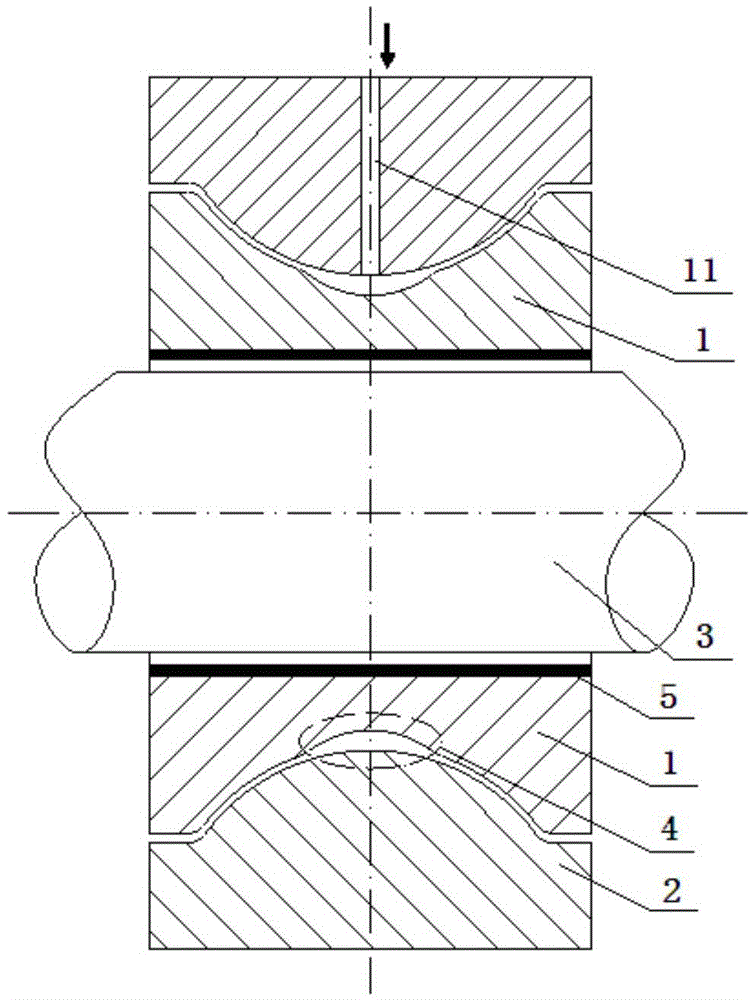

[0019] like figure 1 , Figure 5 As shown, a load-sharing sliding bearing is characterized in that it includes an inner spherical bearing bush 1 and an outer spherical bushing 2; the inner spherical bearing bush 1 and the outer spherical bushing 2 form a spherical fit, and the inner spherical bearing bush 1 There is a rigidity-reducing groove 4 on the spherical surface; the inner spherical bearing 1 is the upper and lower halves of the split support bearing; the rigidity-reducing groove 4 is an annular groove with a cross-sectional shape of an arc shape, and the annular angle β is 360° ; There is space for storing lubricating oil in the annular gap between the inner spherical bearing 1 and the outer spherical bushing 2 in the rigidity-reducing groove 4 ;

Embodiment 2

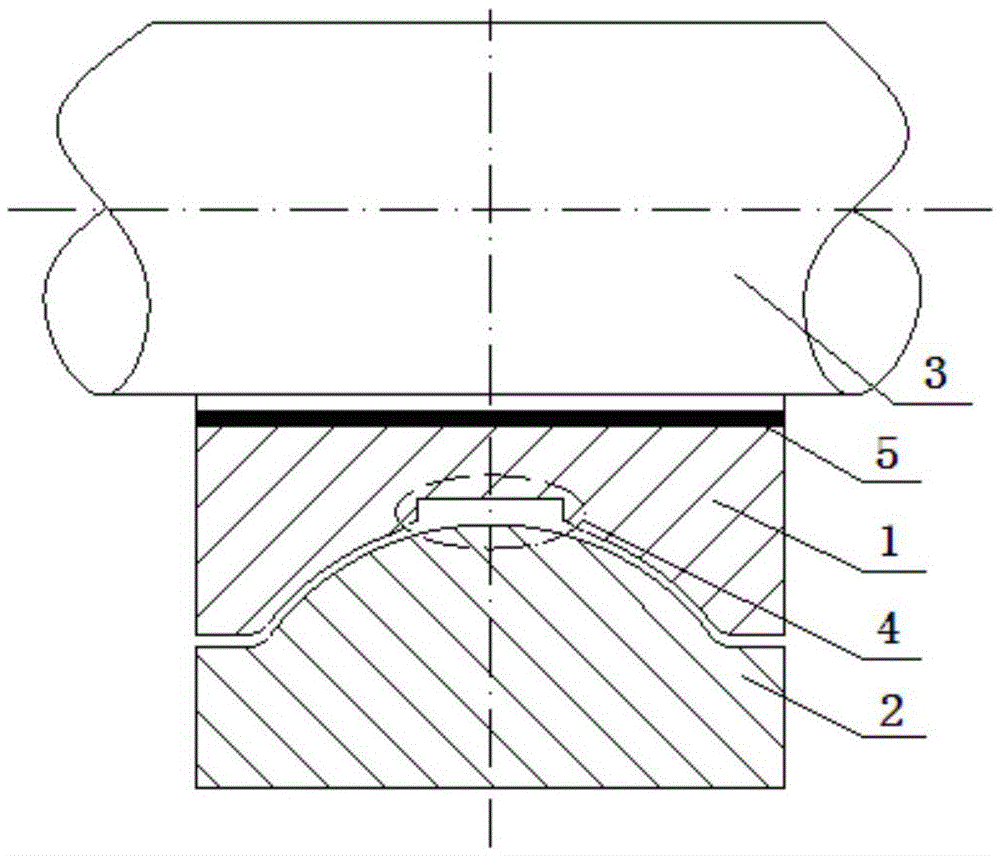

[0021] like figure 2 , Figure 5 As shown, a load-sharing sliding bearing is characterized in that it includes an inner spherical bearing bush 1 and an outer spherical bushing 2; the inner spherical bearing bush 1 and the outer spherical bushing 2 form a spherical fit, and the inner spherical bearing bush 1 There is a rigidity-reducing groove 4 on the spherical surface; the inner spherical bearing 1 is the upper and lower halves of the split support bearing; the rigidity-reducing groove 4 is a rectangular annular groove with a cross-sectional shape, and the annular angle β is 180°; There is a lubricating oil storage space in the annular gap of the rigidity-reducing groove 4 between the inner spherical bearing bush 1 and the outer spherical bushing 2 .

Embodiment 3

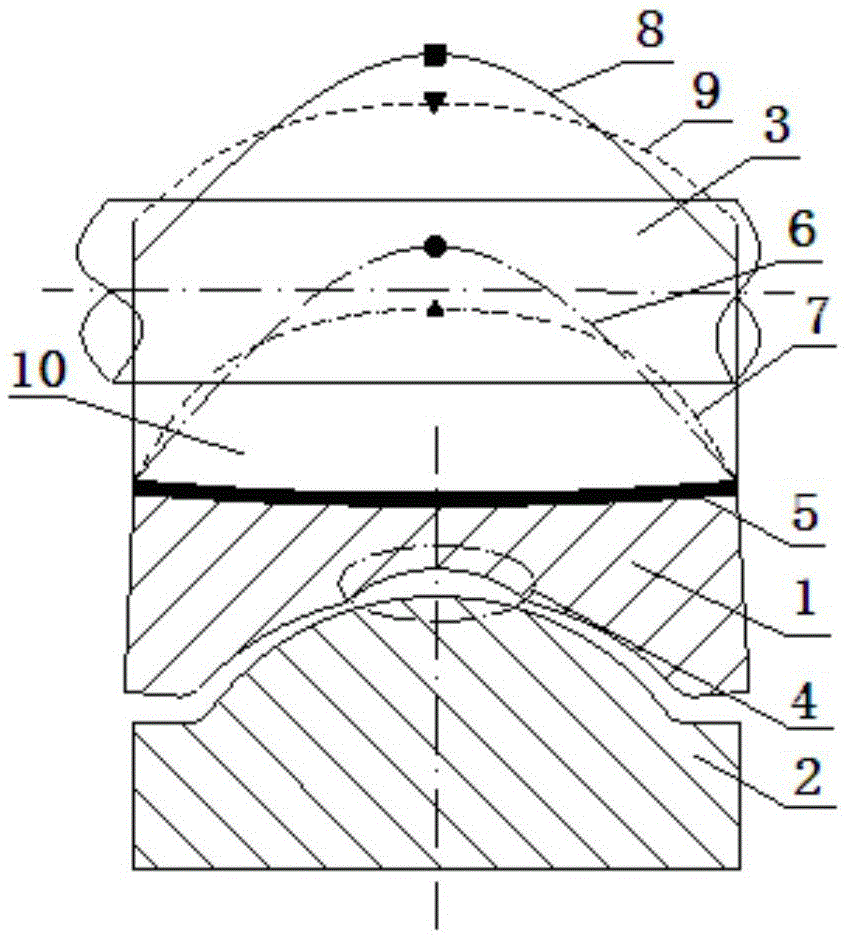

[0023] like image 3 , Figure 5 As shown, a load-sharing sliding bearing is characterized in that it includes an inner spherical bearing bush 1 and an outer spherical bushing 2; the inner spherical bearing bush 1 and the outer spherical bushing 2 form a spherical fit, and the inner spherical bearing bush 1 There is a rigidity-reducing groove 4 on the spherical surface; the inner spherical bearing 1 is the upper and lower halves of the split support bearing; the rigidity-reducing groove 4 is an annular groove with a cross-sectional shape of a spline curve, and the annular angle β is 120° °; There is a space for storing grease in the annular gap between the inner spherical bearing bush 1 and the outer spherical bushing 2 in the rigidity-reducing groove 4 .

[0024] like Figure 4 As shown, the rotary groove designed at the axial center position of the bearing pad with an inner spherical surface in the present invention is the rigidity-reducing groove 4 that reduces the rigidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com