Torque Overload Protector

An overload protector, steel ball technology, applied in the direction of coupling, slip coupling, mechanical equipment, etc., can solve the problems of complicated assembly, complex structure, poor applicability, etc., achieve simple structure, solve complex structure, easy Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

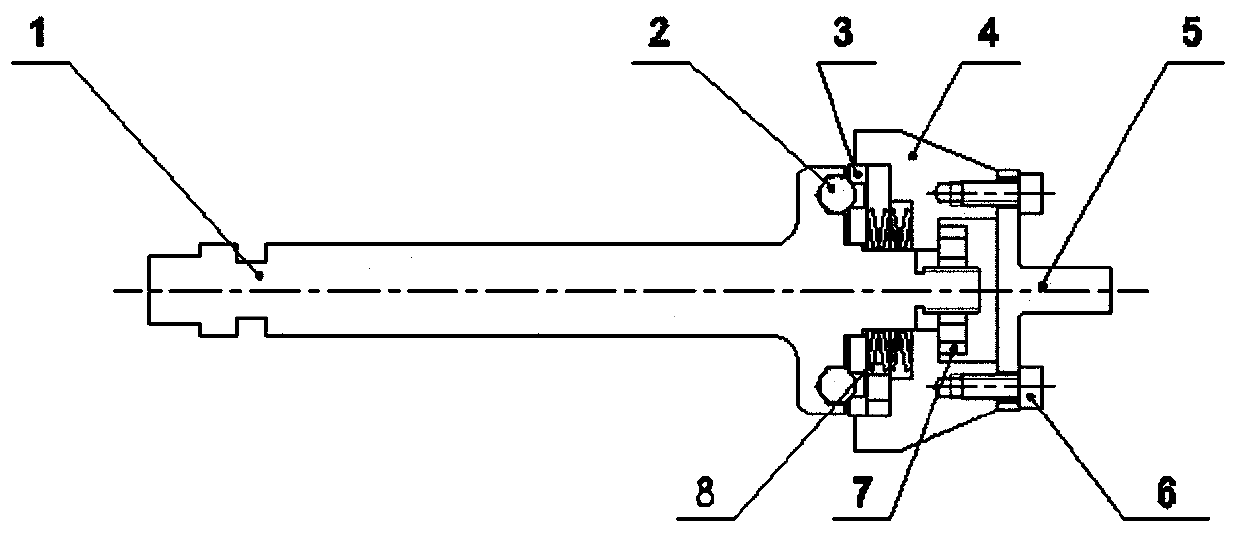

[0016] The torque overload protector includes a main shaft 1 and an end cover shaft 5, and is characterized in that: the steel ball 2 is embedded in the groove of the main shaft 1, the clutch plate 3 is attached to the steel ball 2, and the other end of the clutch plate 3 is connected with a coupling sleeve 4 The disc spring 8 is clamped, and the lock nut 7 is used to tighten the coupling sleeve 4 on the main shaft 1 to preload the disc spring 8 , and the end cover shaft 5 is fixed on the coupling sleeve 4 through the screw 6 .

[0017] The combination sleeve 4 is an integral structure, which is a circular platform structure as a whole, and a circular through hole is arranged inside, and the inner surface of the combination sleeve 4 opposite to the steel ball 2 is sequentially provided with stepped butterfly spring clips from the inside to the outside. Groove and clutch plate slot, the inner surface of the coupling sleeve 4 opposite to the end cover shaft side is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com