Low-temperature regeneration combined type turning wheel dehumidifying unit

A technology of rotary dehumidification and low-temperature regeneration, applied in the field of air-conditioning units, can solve the problems of high regeneration energy consumption, high regeneration temperature, and high cost, and achieve the effect of improving energy efficiency ratio, reducing regeneration energy consumption, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

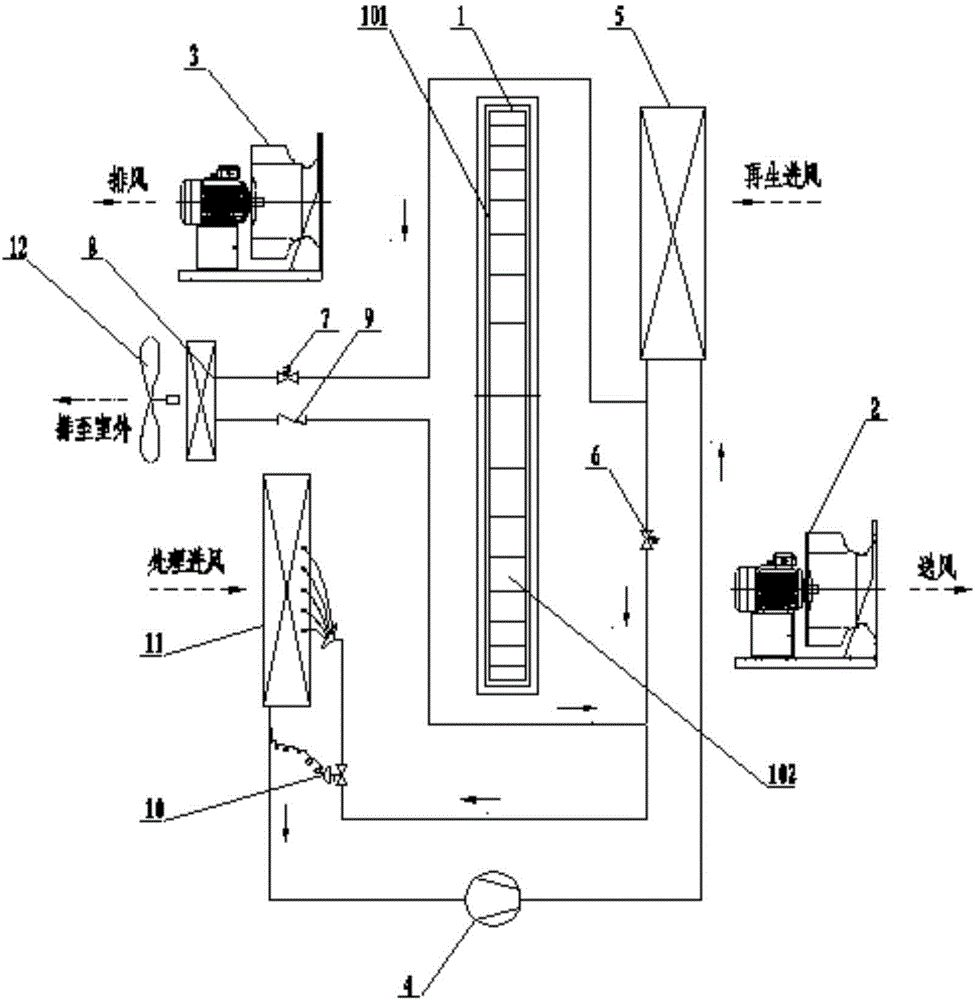

[0022] Such as figure 1 As shown, a low-temperature regenerative compound dehumidifier unit includes a dual-air duct air system composed of a regeneration air channel and a treatment air channel; it also includes a refrigeration device, a dehumidification rotor 1, a blower 2 and a regeneration fan 3; The refrigerating device includes a compressor 4, a reheating condenser 5, a first solenoid valve 6, a second solenoid valve 7, a bypass condenser 8, a one-way valve 9, a throttling component 10 and an evaporator 11; the compressor 4 The exhaust end of the exhaust port is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com