Device and method for measuring friction characteristics of rocking bearing under the combined action of shaft radial load

A radial load and co-action technology, which is used in measuring devices, mechanical bearing testing, and the use of mechanical devices to achieve the effects of accurate bearing rocking boundaries, high load loading accuracy, and high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

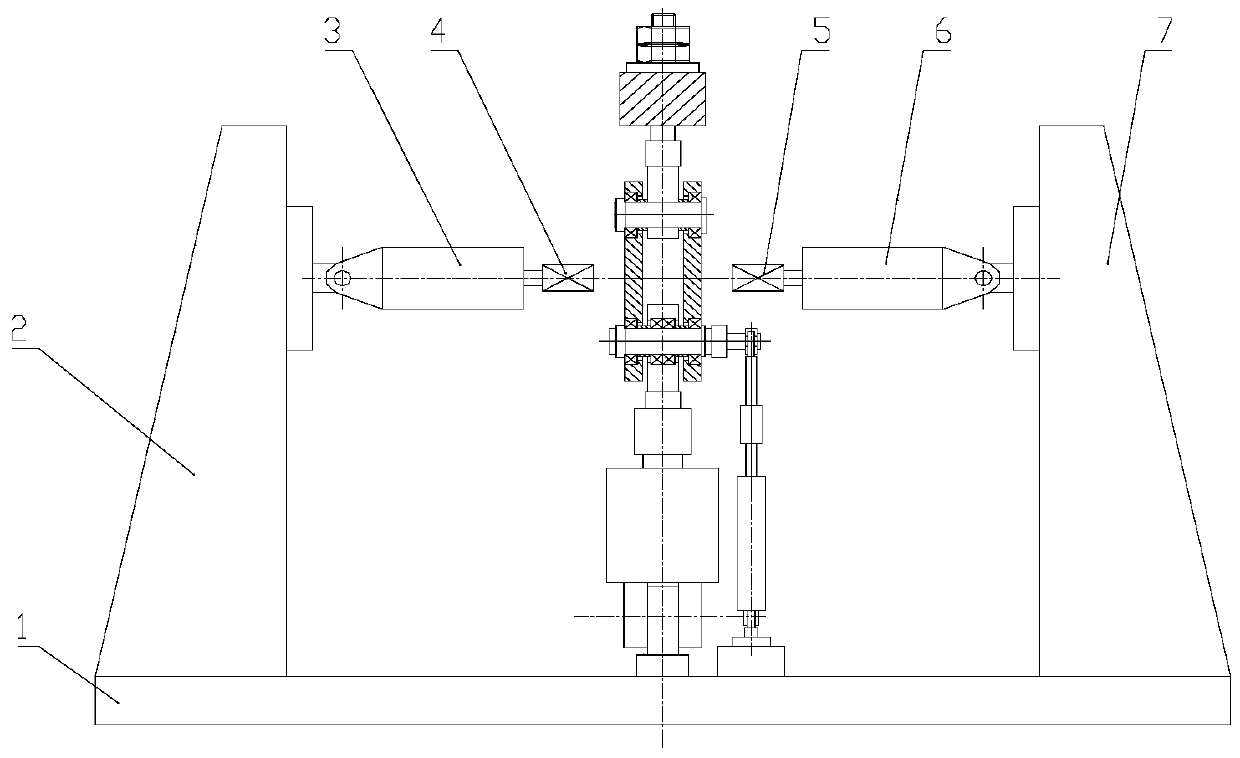

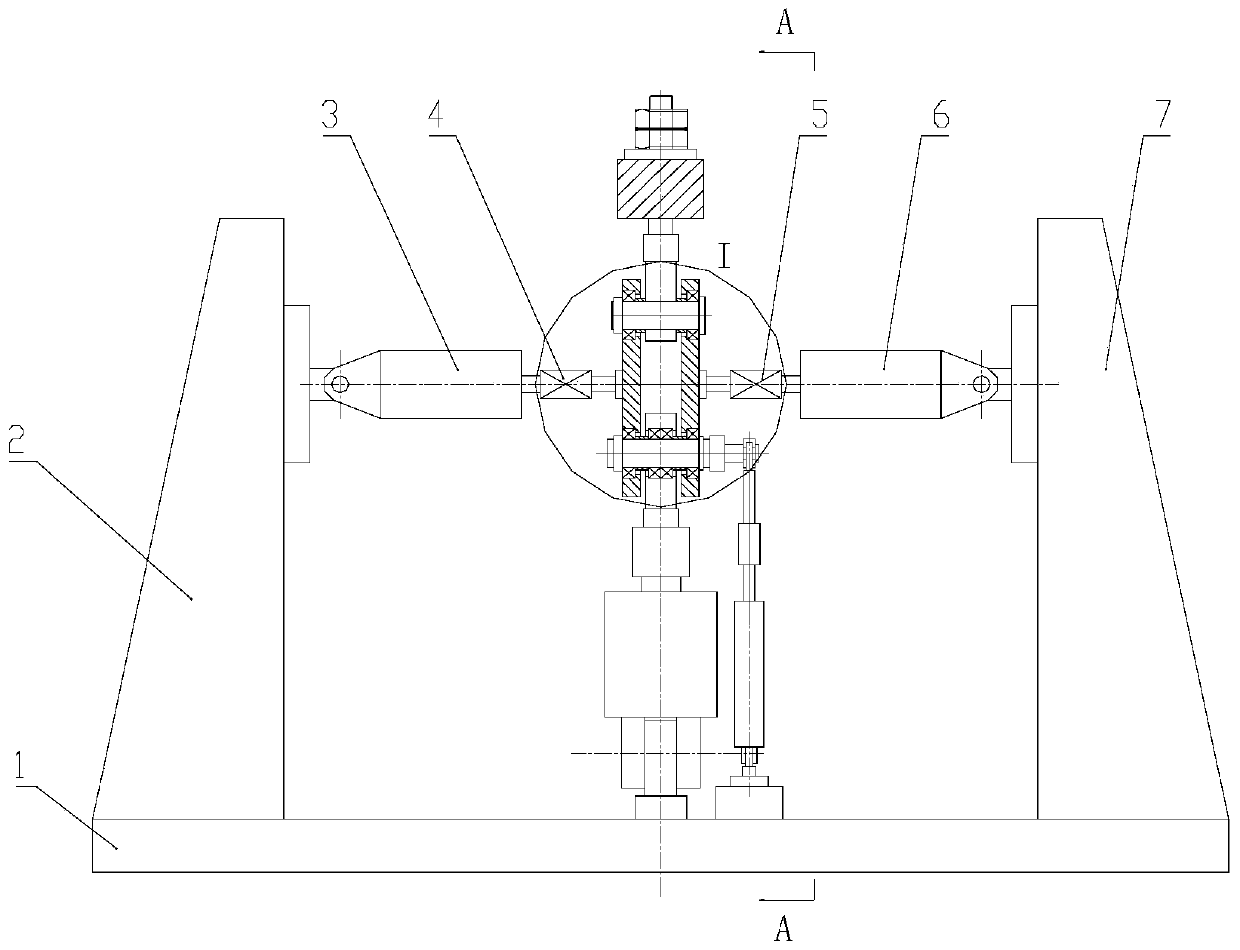

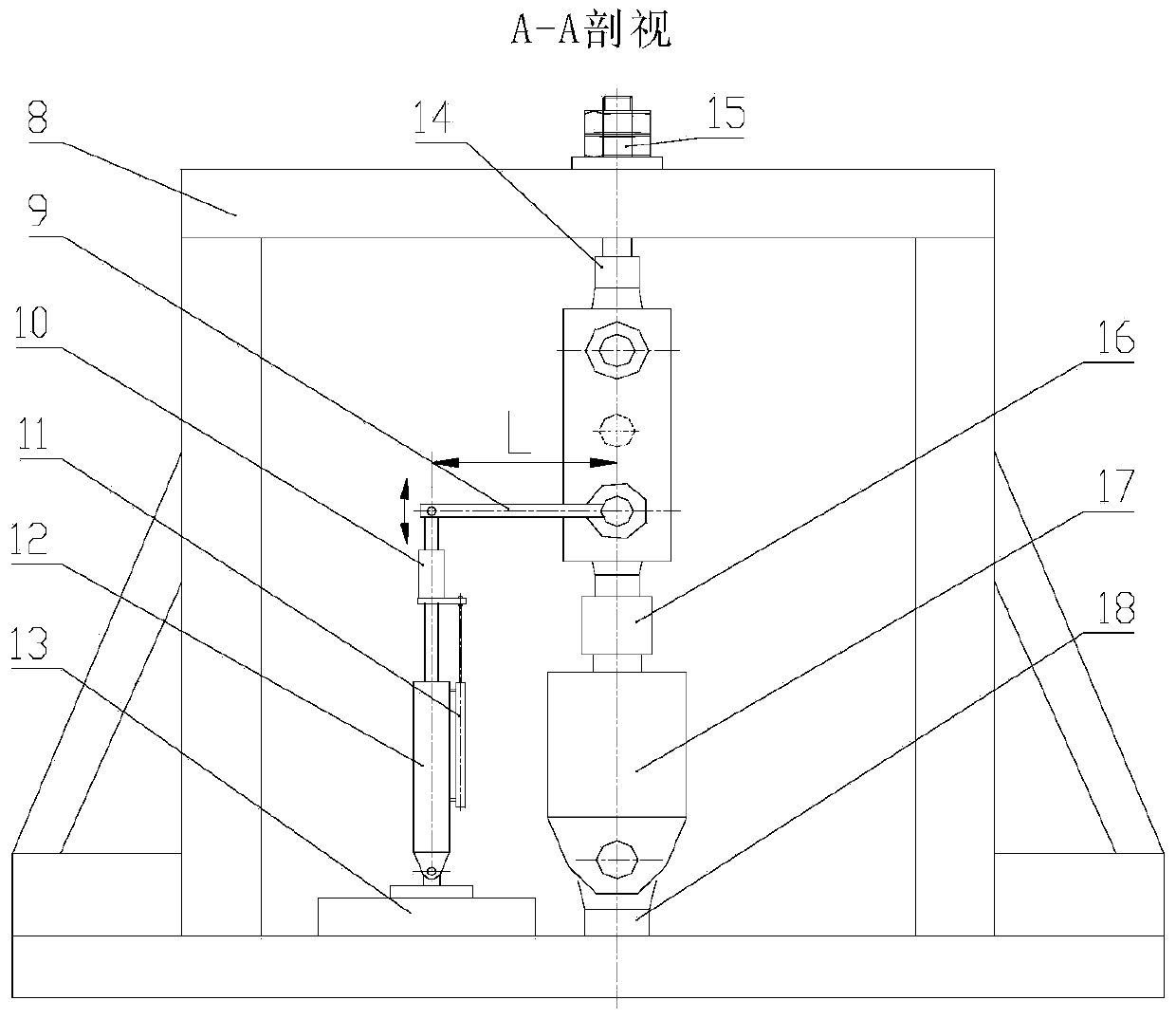

[0048] (1) attached figure 1 , attached image 3 , attached Figure 4 The process bearing 25, the test bearing 23 and the auxiliary bearing 19 with an inner diameter of 70 mm, an outer diameter of 105 mm, an inner ring width of 49 mm, and an outer ring width of 40 mm are combined with the swing shaft 22, the process shaft 20, the bearing plate 21, and the diameter of the radial loading assembly. Install the servo oil cylinder 17, the third load sensor 16, the gantry frame 8, the bearing platform 1, etc. to the load. One end of the process shaft 20 is designed as a step, and the other end is a threaded structure, and the threaded end is fixed by a nut to constrain the horizontal displacement of each component on the process shaft. The same one end of the rocking shaft 22 is designed as a stepped form, and the other end utilizes a nut to fix and constrain the horizontal displacement of each part on the rocking shaft. 1000mm;

[0049] (2) Radial load loading The servo cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com