Method for calculating iron ore powder mixing working performance by actually measured standard deviation of mixing material pile

A technology of standard deviation and iron ore powder, which is applied in the calculation field of iron ore powder mixing operation process effect, can solve the problems of non-use, difficulty in obtaining autocorrelation function of raw materials, and inaccurate reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

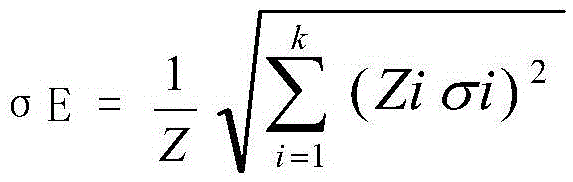

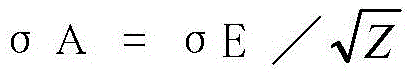

[0113] 1) Use formula (5) to get σa:

[0114] σa can be obtained from the pass rate P data of the mixing stockpile measured in production, using the formula (5), that is, Ф(t / σa)=(1+P) / 2;

[0115] Look up the standard normal distribution function value table, get t / σa=1.81,

[0116] σa=t / 1.81=0.008 / 1.81=0.0044.

[0117] 2) Use the theoretical calculation σa to calculate the mixing efficiency of the iron ore powder mixing operation process:

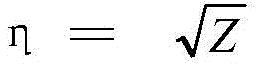

[0118] η = P ( A ) [ 1 - P ( A ) ] / σ a = 0.867 × 0.133 / 0.0044 = 77.176.

[0119] 3) Use the actual measuremen...

Embodiment 2

[0122] 1) Use formula (5) to get σa:

[0123] σa can be obtained from the data of the pass rate P of the mixing stockpile measured in production, using the formula (5), that is, Ф(t / σa)=(1+P) / 2;

[0124] Look up the standard normal distribution function value table, get t / σa=1.15,

[0125] σa=t / 1.15=0.008 / 1.15=0.007.

[0126] 2) Use the theoretical calculation σa to calculate the mixing efficiency of the iron ore powder mixing operation process:

[0127] η = P ( A ) [ 1 - P ( A ) ] / σ a = 0.863 × 0.137 / 0.007 = 49.114.

[0128] 3) Use the actual measu...

Embodiment 3

[0131] 1) Use formula (5) to get σa:

[0132] σa can be obtained from the pass rate P data of the mixing stockpile measured in production, using the formula (5), that is, Ф(t / σa)=(1+P) / 2;

[0133] Check the standard normal distribution function value table, get t / σa=1.75,

[0134] σa = t / 1.75 = 0.008 / 1.75 = 0.0046.

[0135] 2) Use the theoretical calculation σa to calculate the mixing efficiency of the iron ore powder mixing operation process:

[0136] η = P ( A ) [ 1 - P ( A ) ] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com