SLM microscopic vision data reconstruction method by using residual feedback

A microscopic vision and residual feedback technology, applied in image data processing, 3D image processing, instruments, etc., can solve problems such as reducing micro-measurement, misoperation, and difficulty in using models, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

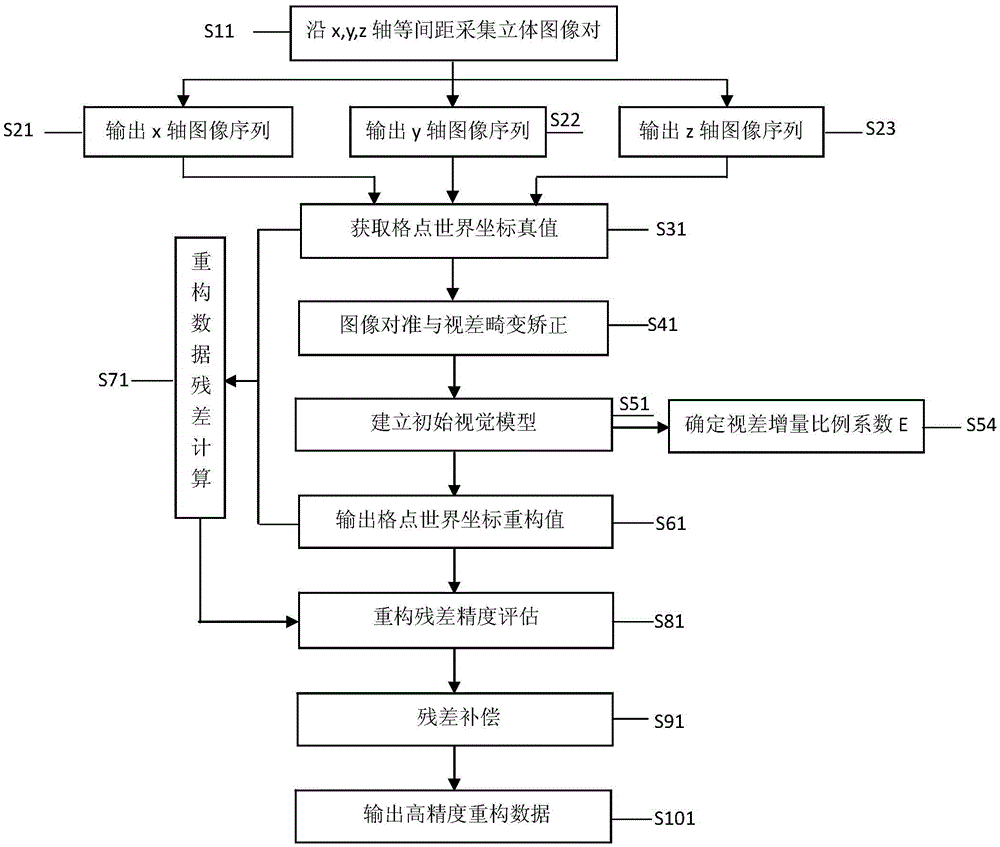

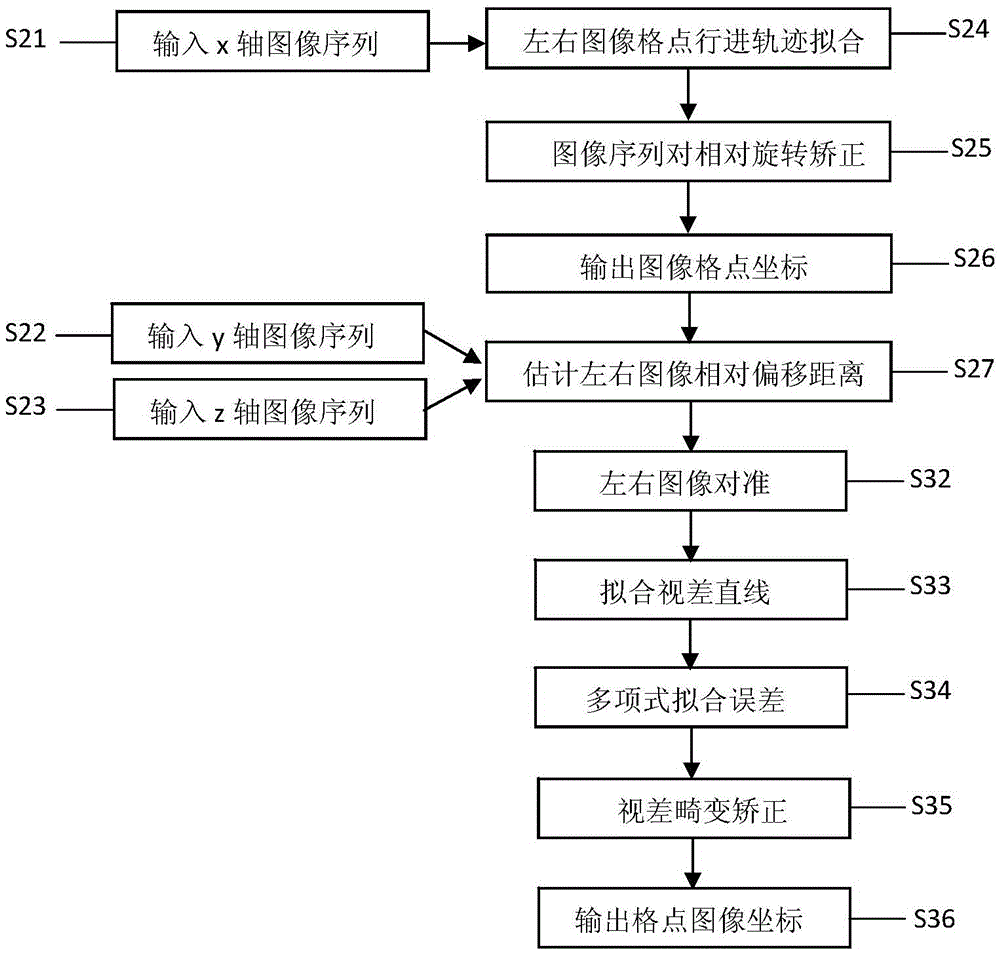

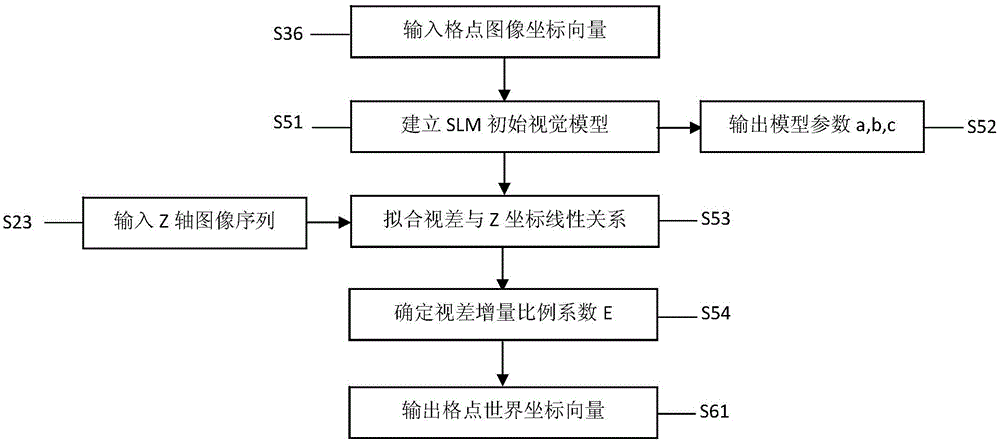

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. figure 1 Show the flow chart of the SLM micro-visual data reconstruction method using residual feedback involved in the present invention, as shown in the figure, the SLM micro-visual data reconstruction method using residual feedback includes the following steps:

[0027] 1. Equidistant acquisition of SLM stereo image pairs

[0028] Make a grid-like plane calibration template by MEMS technology, design a circular pattern with 7 rows x 7 columns, the diameter is 0.15mm, the circular spacing of adjacent logo patterns is 0.3mm, and the positioning accuracy of the array grid points is ±0.25μm , the center point of the circular pattern is defined as the grid point. Fix the calibration template on the driving device, and the image acquisition plane is basically located at the focal plane of the SLM. The SLM has an effective depth range centered on the focal plane. The effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com