Fuel assembly and fuel rod capable of improving reactor security of fuel assembly

A fuel assembly and fuel rod technology, applied in the field of nuclear power, can solve the problems of poor safety, fuel rod line power density limitation, high nuclear fuel energy storage, etc., to reduce the probability of deviation from nucleate boiling, increase safety margin, and increase heat transfer area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

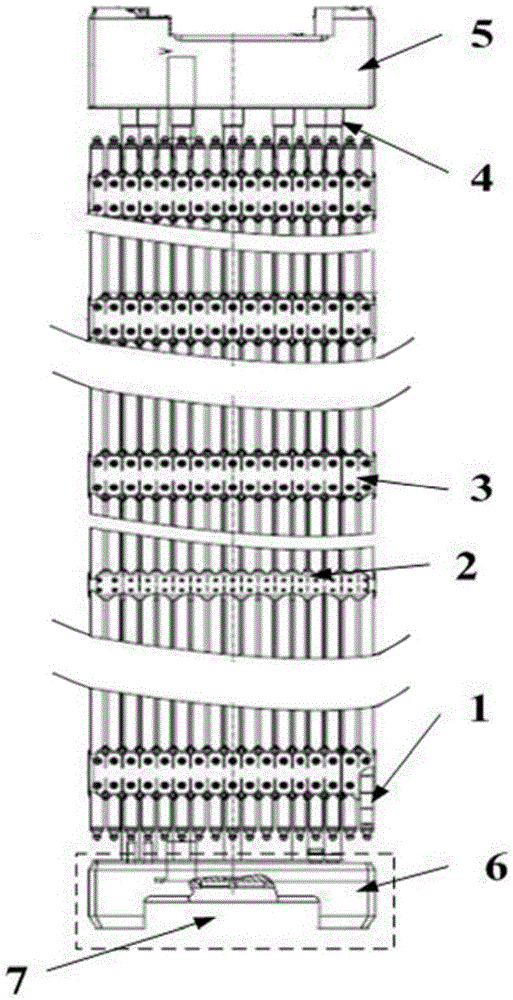

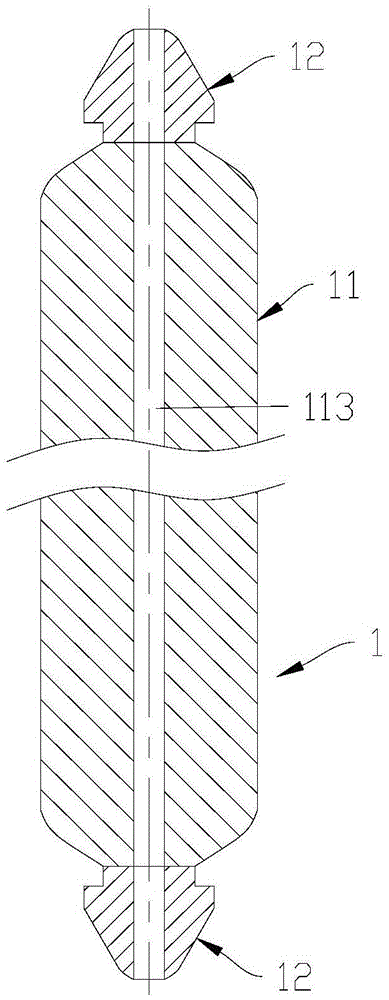

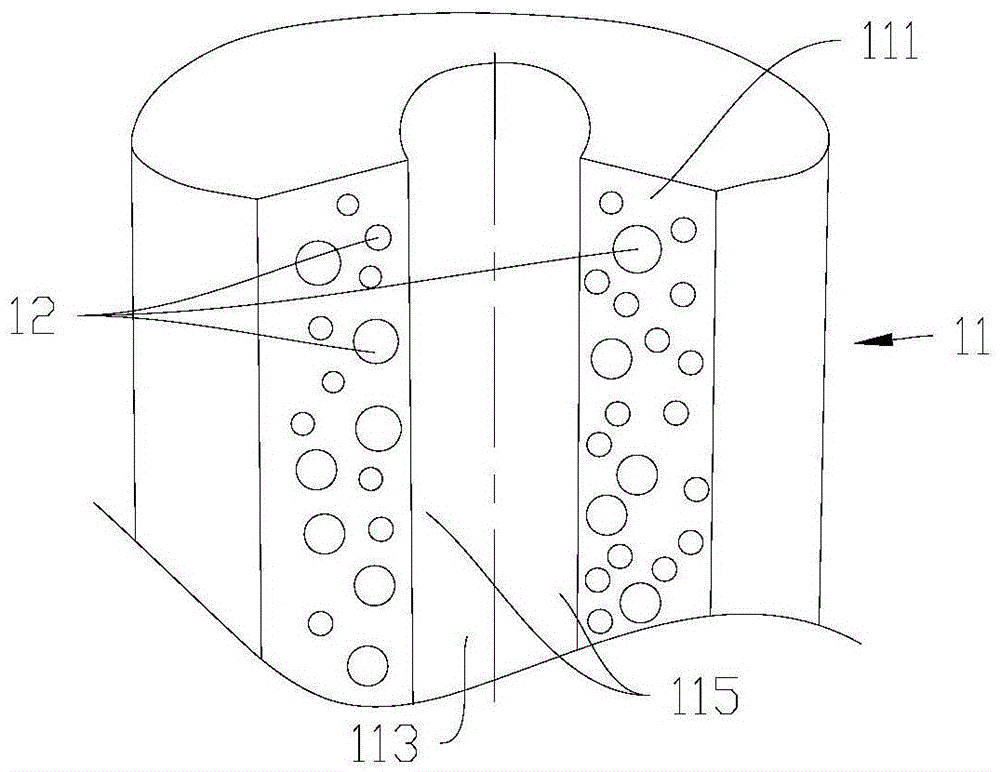

[0042] Such as figure 1 As shown, the fuel assembly in a preferred embodiment of the present invention includes a fuel rod 1 , a mixing grid 2 , a spacer grid 3 , a guide tube 4 , and an upper tube base 5 and a lower tube base 6 . The mixing grid 2 includes several mixing cells arranged at intervals along the axial direction of the fuel rod 1 , and the number of the spacer grids 3 is usually multiple, arranged at intervals along the axial direction of the fuel rod 1 . Fuel rod 1 and guide tube 4 are clamped and fixed on the mixing grid 2 and the positioning grid 3, and the two ends of the guide tube 4 stretch out from the two ends of the fuel rod 1 to cooperate with the upper tube base 5 and the lower tube base 6 respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com