Gas purge device and gas purge method

A gas cleaning and gas introduction technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, optics, etc., can solve problems such as cleaning gas leakage, hindering container sliding, and poor container positioning, so as to improve durability and prevent leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

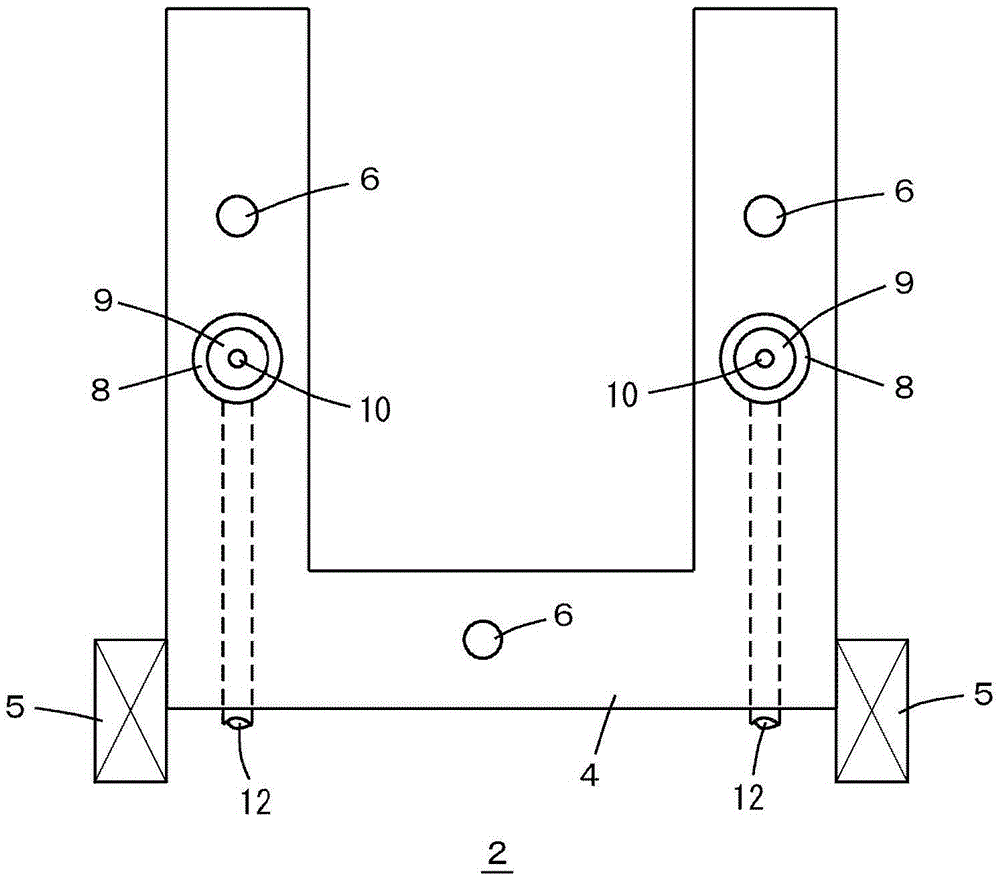

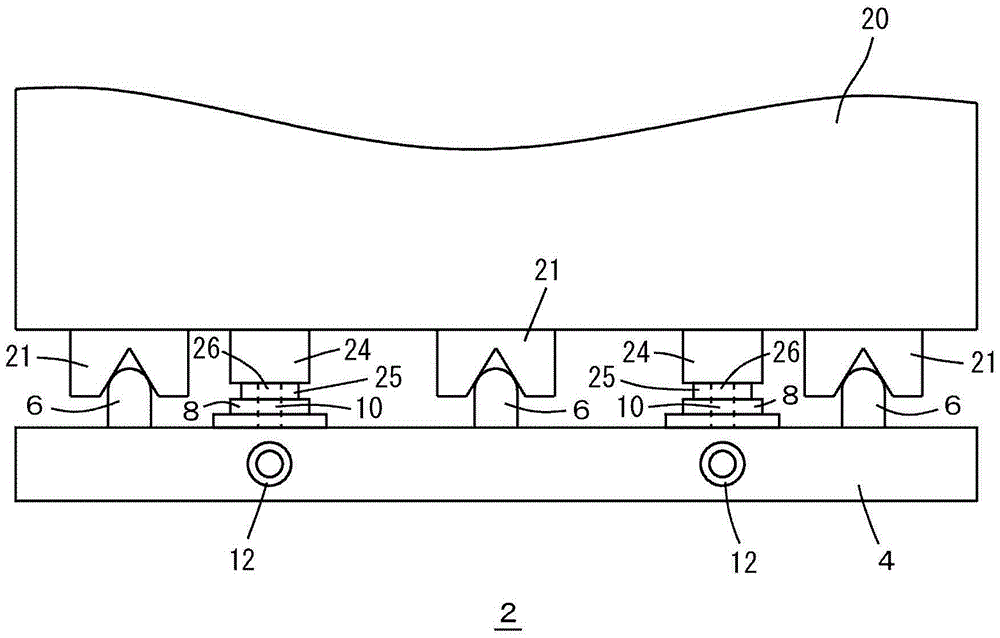

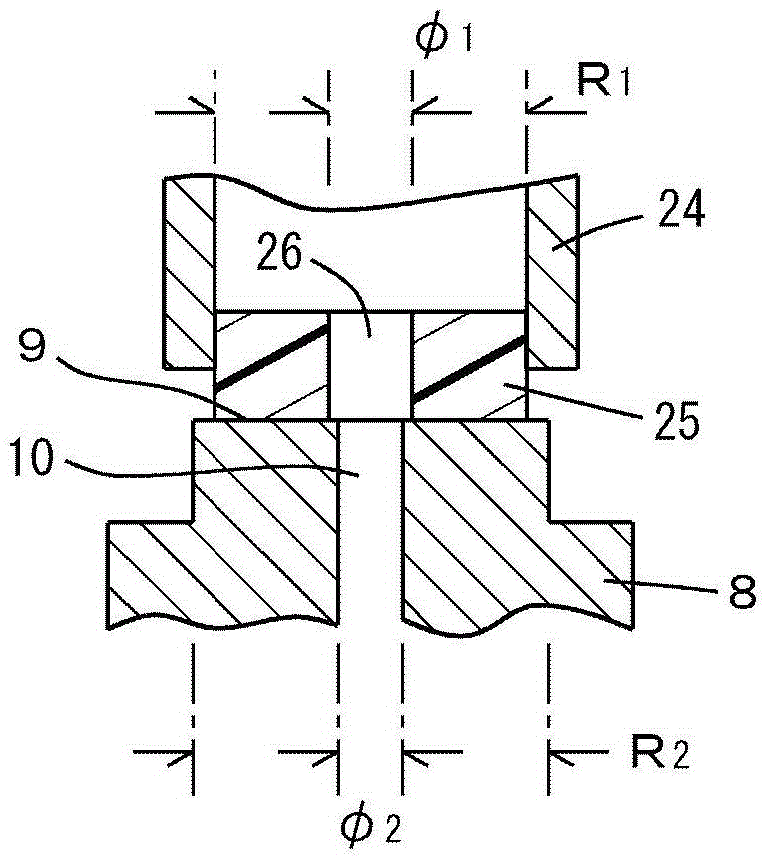

[0031] Figure 1 to Figure 7 Indicates an example. The gas cleaning device 2 is installed in, for example, a storage or an automated warehouse, and positions and stores containers containing semiconductor substrates and reticles, while supplying cleaning gas into the containers. 4 is a shelf seat, which is supported by the pillar 5 of the storage. For example, three pins 6 protrude from the shelf seat 4, and are connected in the positioning groove of the storage to position the container. 8 is a nozzle for introducing cleaning gas, one or two are provided, protruding from the shelf base 4 to the upper part. The tip of the nozzle 8 has a circular tip surface 9, and a circular nozzle hole 10 is provided at the center thereof. Moreover, the material of the nozzle 8 is, for example, durable stainless steel, and the pipeline 12 of the cleaning gas is connected to the nozzle 8, and the nozzle 8 is fixed on the shelf base 4, that is, neither lifts nor slides horizontally.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com