Welding anti-adhesion structure, welding device and welding method

A welding device and welding method technology, applied in welding/welding/cutting items, auxiliary devices, welding equipment, etc., can solve the problem of easy adhesion between the workpiece to be welded and the tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

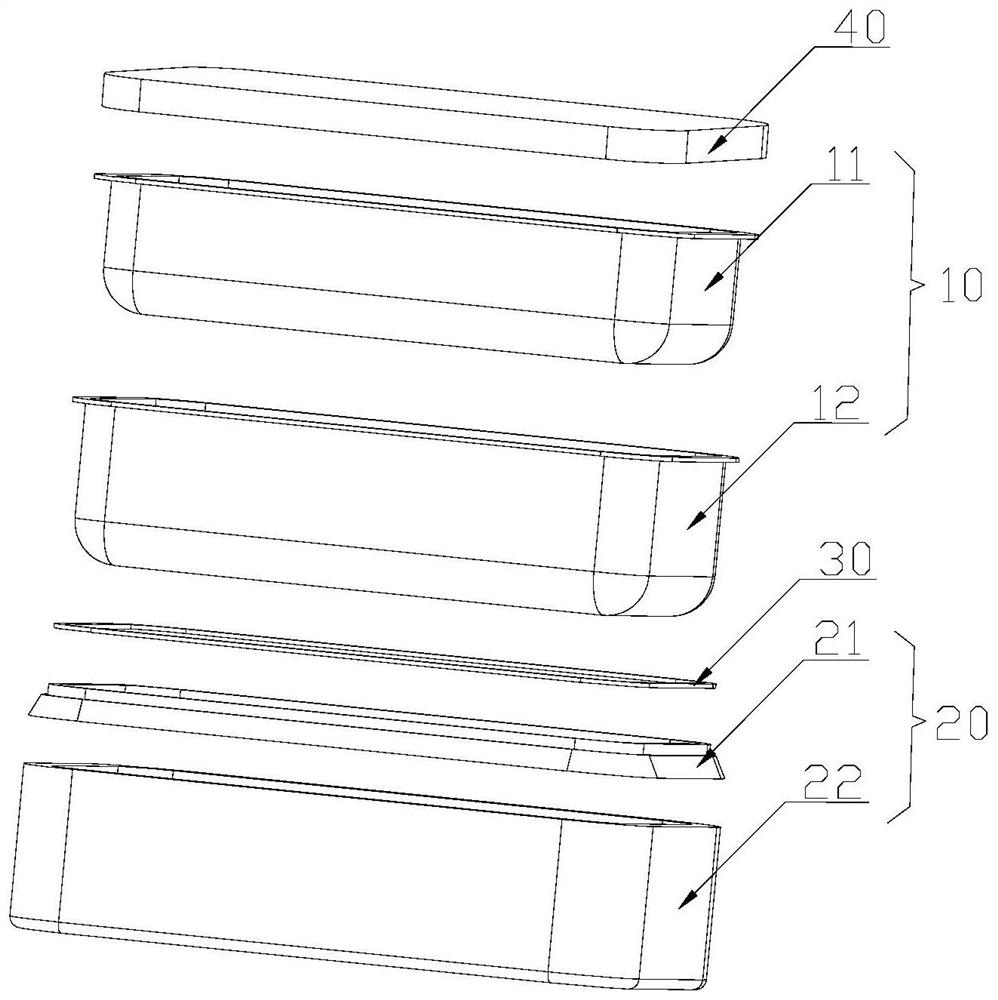

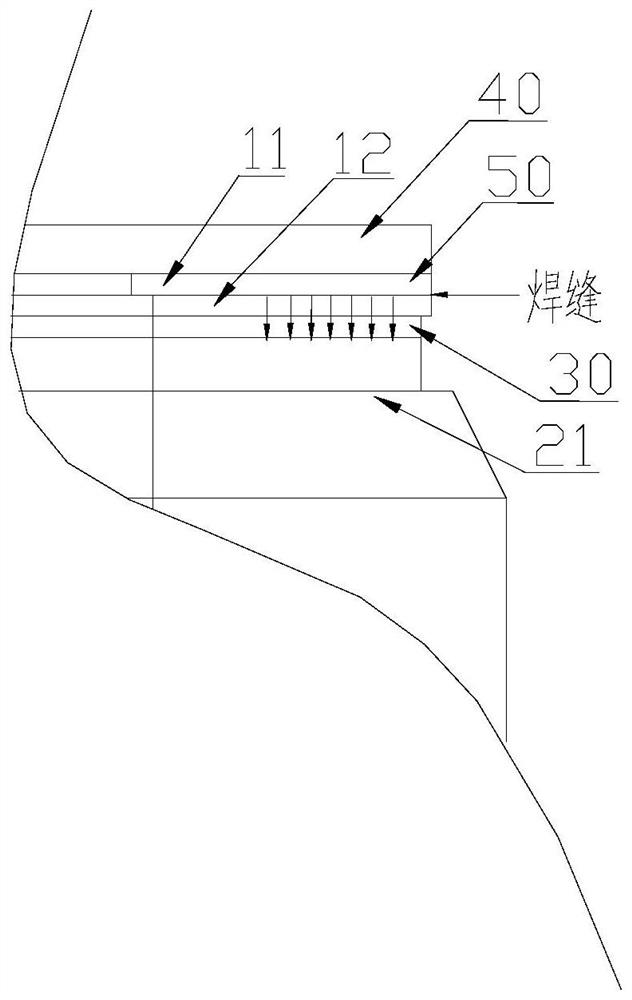

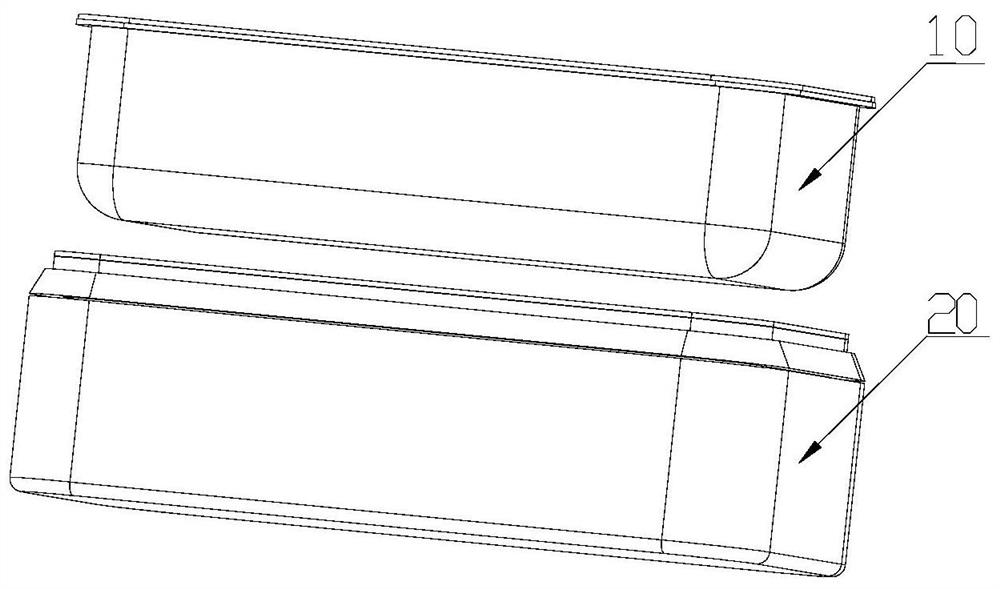

[0026] The present invention provides a welding anti-adhesion structure, comprising a piece to be welded, a welding tool 20 and a spacer 30 arranged between the piece to be welded and the welding tool 20, and the spacer 30 has chemical stability and thermal stability, preventing During welding, the weldment and the welding tooling 20 are oxidized and / or melted at high temperature to be bonded together.

[0027] The spacer 30 has chemical stability and thermal stability, and can isolate the piece to be welded and the welding tool 20. During welding, the piece to be welded and the welding tool 20 are not easy to produce oxidation reaction and adhesion, and will not stick to each other due to high temperature melting, eliminating The problem of easy adhesion between the workpiece to be welded and the welding tool 20 during the welding process improves work efficiency and product quality.

[0028] As an optional implementation manner, the spacer 30 is covered and fixed on the weld...

Embodiment 2

[0030] The welding anti-adhesion structure includes the piece to be welded, the welding tool 20, and the spacer 30 arranged between the piece to be welded and the welding tool 20. The spacer 30 is made of ceramic-magnesium-based composite material, which is high temperature resistant, wear resistant, strong and tough. Features, when welding stainless steel, it will not react with other materials, and has good stability, preventing the weldment and the welding tool 20 from being oxidized and adhering to each other during welding.

Embodiment 3

[0032] The welding anti-adhesion structure includes the piece to be welded, the welding tool 20, and the spacer 30 arranged between the piece to be welded and the welding tool 20. The difference between embodiment 3 and embodiment 2 is that the spacer 30 is made of bakelite material. The bakelite material has the characteristics of high temperature resistance, wear resistance, and strong toughness, which prevents the welding parts and welding tooling from melting at 20°C at high temperature during welding to prevent them from sticking together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com