Casting shakeout hopper based on timing forward and reverse rotation control

A forward-reversing, sand-shaking bucket technology, which is applied in the direction of manufacturing tools, casting molding equipment, and cleaning/processing machinery for mold materials, can solve the problems of low sand-shaking efficiency and high labor intensity, and achieve continuous The effect of feeding materials, improving feeding efficiency, reducing labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

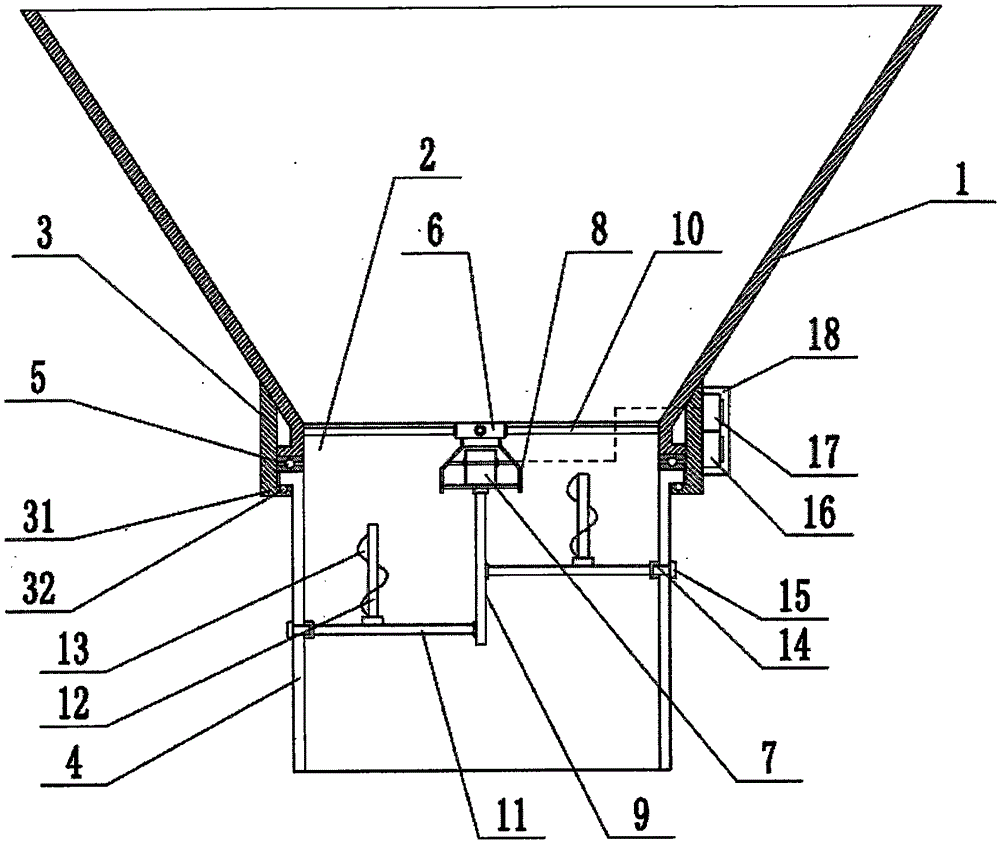

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the sand shakeout bucket for casting based on timing forward and reverse control in this embodiment includes a bucket body 1, the lower end of the bucket body 1 has a discharge port 2, and a support sleeve 3 is installed on the outside of the discharge port 2 to support The inner side of the cover 3 is equipped with a material guide sleeve 4, and the material guide sleeve 4 is installed between the lower end of the discharge port 2 and the inner fold ring 31 of the support sleeve 3 through the thrust bearing 5, and in the ring groove on the upper surface of the inner fold ring 31. Balls 32 are installed; the inner wall of the discharge port 2 is equipped with a support base 6 through a plurality of support rods 10, and the lower surface of the support base 6 is equipped with a motor protection cover 8 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com