Five-axis cutting machine

A technology of cutting machine and rotating shaft, which is applied in the direction of metal processing machinery parts, manufacturing tools, positioning devices, etc., can solve the problems of unreasonable structure setting of five-axis cutting machine and cannot meet the requirements of use, so as to ensure the consistency of size and facilitate collection Detritus, structure set reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

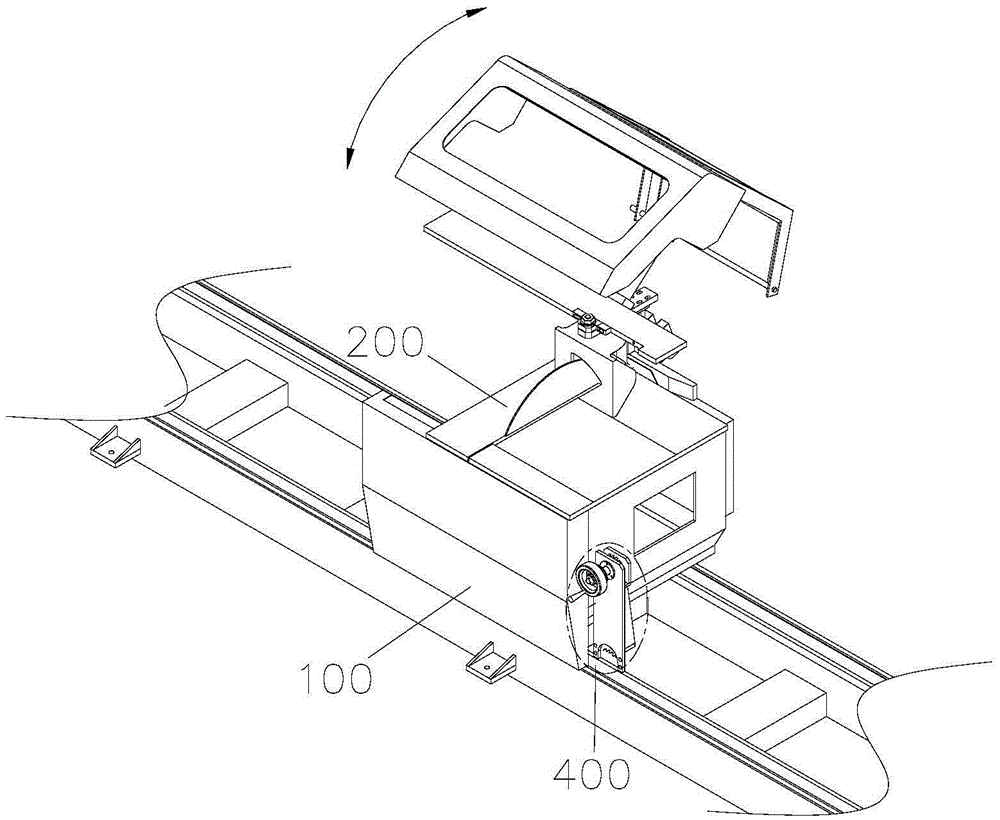

[0033] Such as Figure 1-5 As shown, a five-axis cutting machine includes:

[0034] A base 100 supporting the entire structure;

[0035] A workbench 200 that is arranged on the base 100 and rotates 45° left and right on the base;

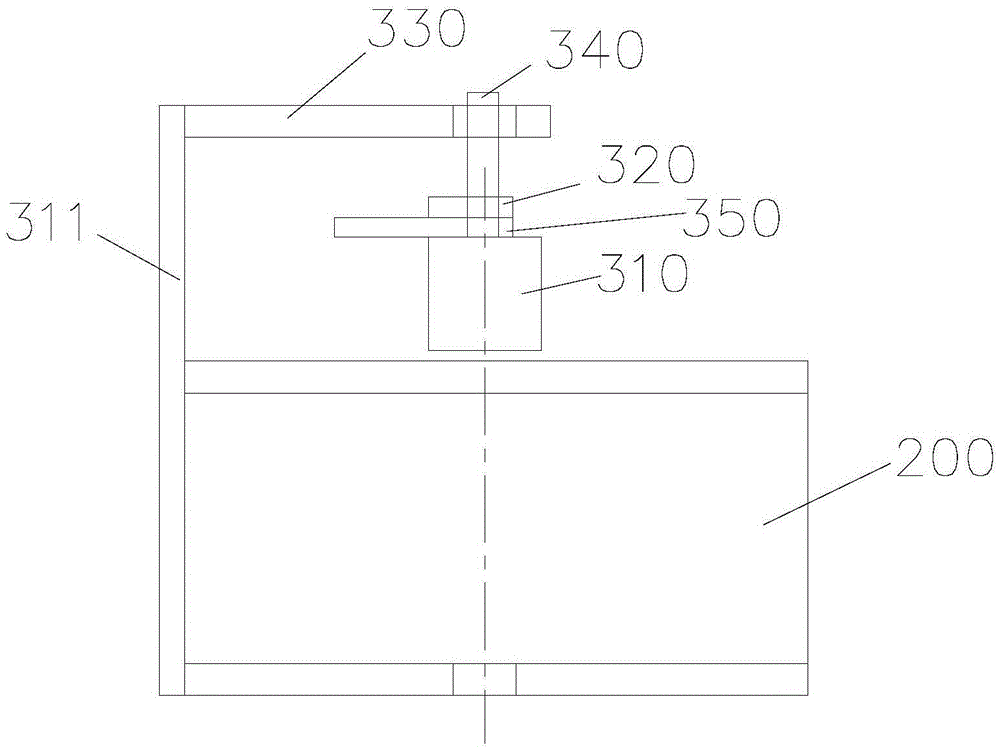

[0036] The feeding and pressing mechanism for feeding and pressing materials;

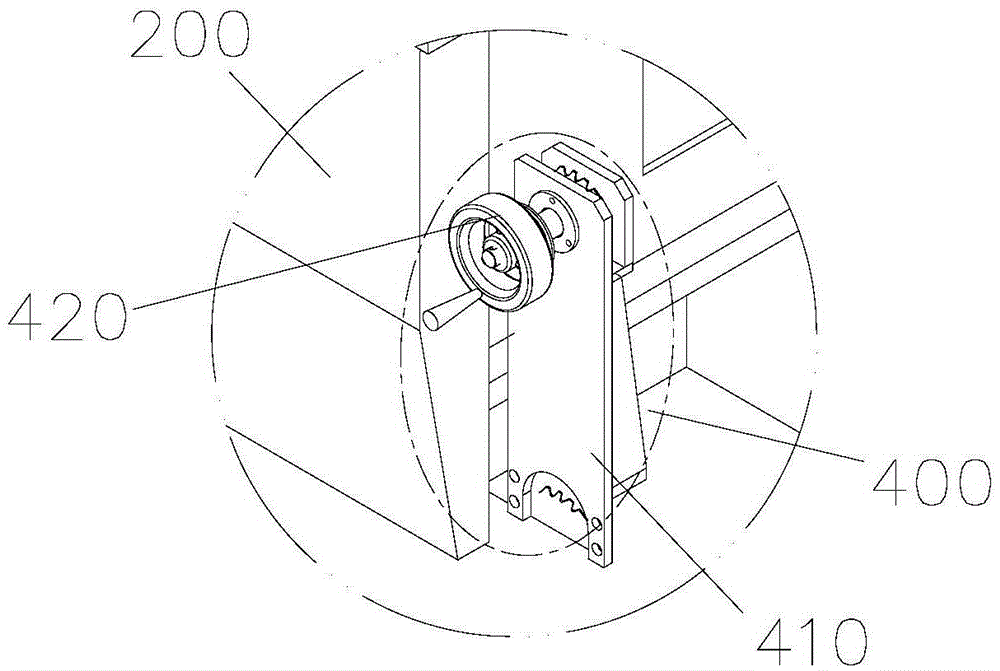

[0037] A fine-tuning sprocket mechanism 400 for driving the workbench 200 to perform micro-precise rotation on the base;

[0038] The feeding and pressing mechanism includes a feeding seat 310 and a pressing power device mounting plate 320 separated from each other; the workbench 200 is connected with a rotating power device, and the rotating power device drives the workbench 200 to rotate over a large distance, fine-tuning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com