Automatic bolt finish-machining device and bolt finish-machining method adopting same

A bolt and equipment technology, applied in the field of automatic bolt finishing equipment, can solve the problems of shortening time, missed detection of bolt threads, false detection, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

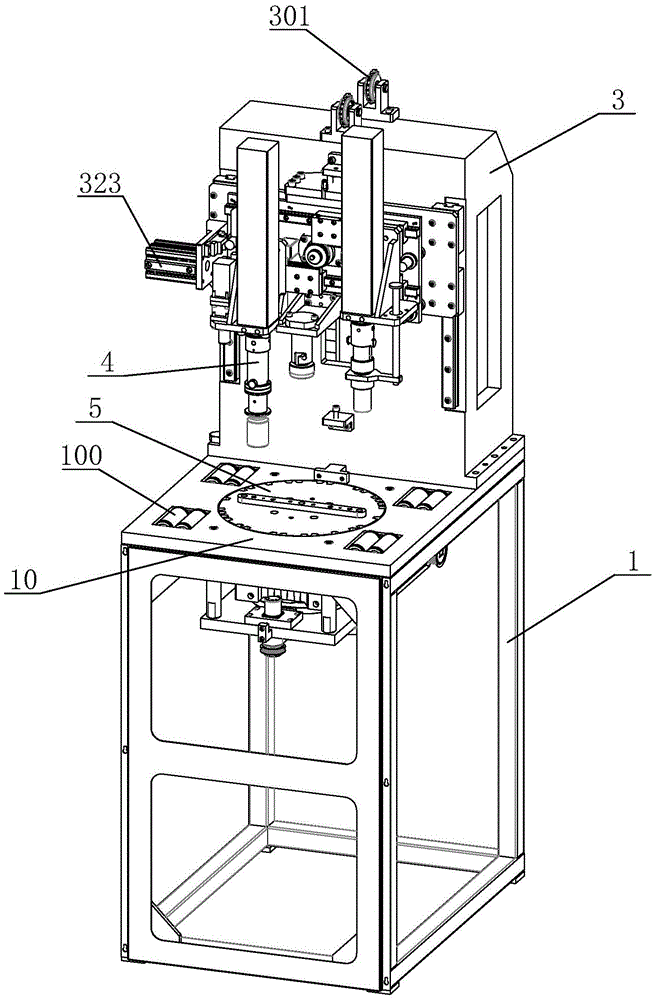

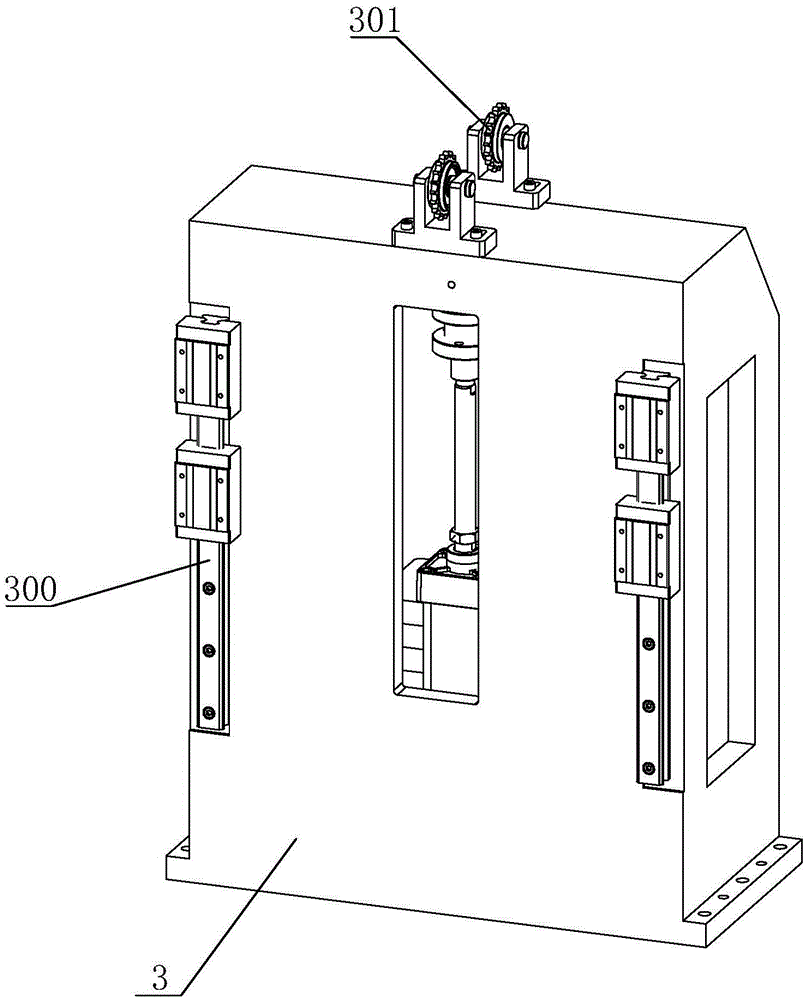

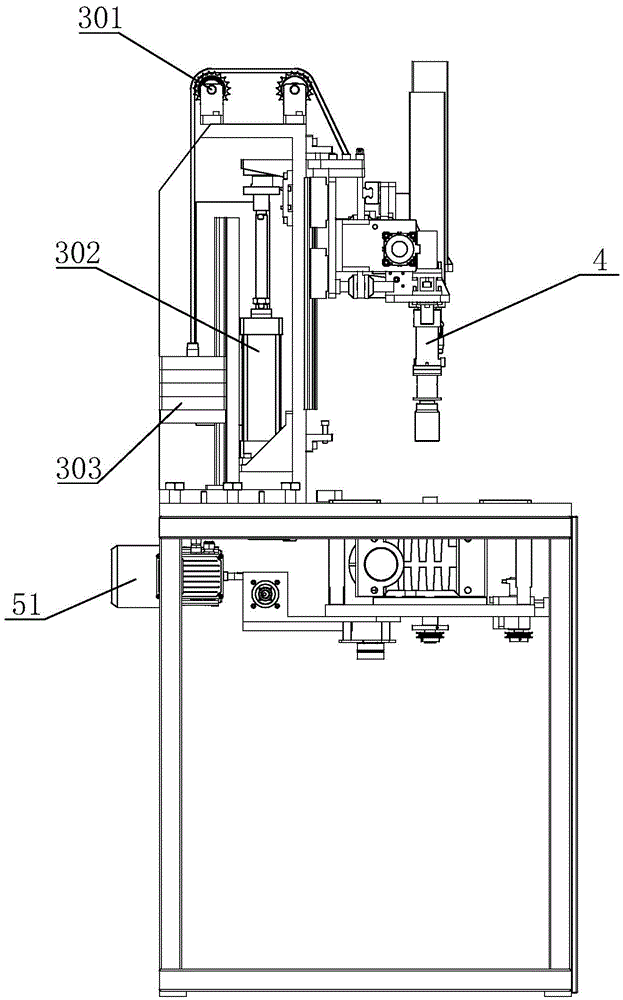

[0052] like Figures 1 to 12 The automatic bolt finishing equipment shown includes a chassis 1, a support 3 and a processing and testing device 4, the processing and testing device 4 is arranged in front of the support, the top of the chassis 1 is a loading panel 10, and the support 3 is fixed on the loading panel 10. The upper surface of the panel 10.

[0053] A rotatable loading platform 5 is provided in the middle of the loading panel 10 , and the bottom frame 1 is provided with a rotation driving device for rotating the loading platform 5 and a rotation limiting device 52 for limiting the rotation angle of the loading platform 5 .

[0054] The rotation driving device 51 is used to drive the rotation of the object stage 5, and the rotation of the object stage can be realized by using a motor in cooperation with a gear box or other components.

[0055] The rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com