Automatic conducting strip sticking, welding and bending equipment and machining technology thereof

An automatic patch, conductive sheet technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of conductive sheet falling off, difficult to control, slow manual operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

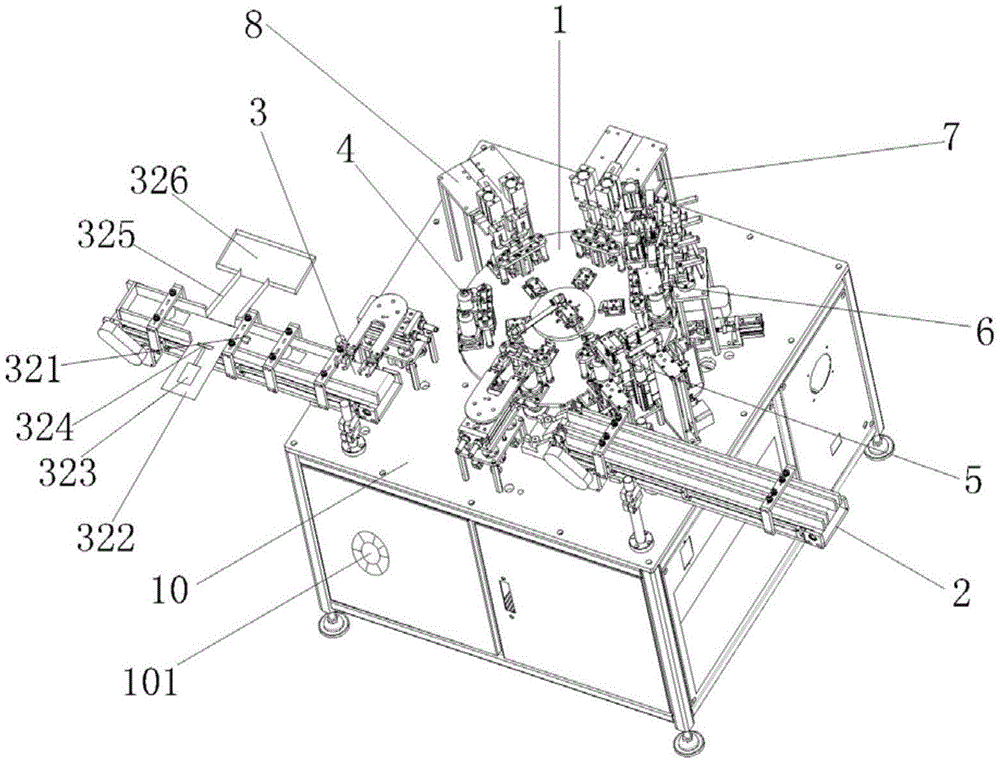

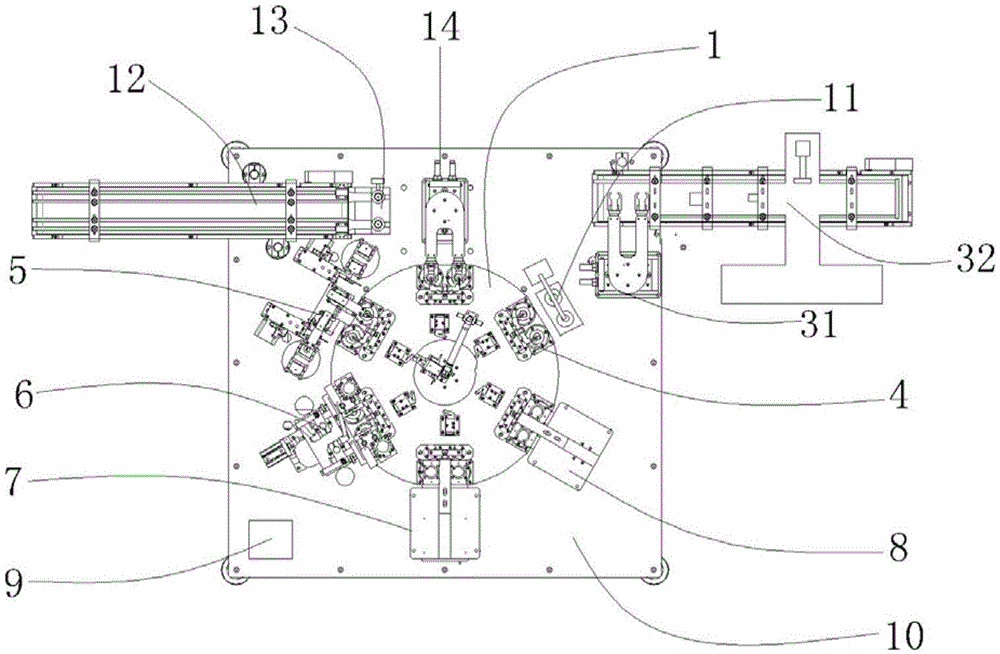

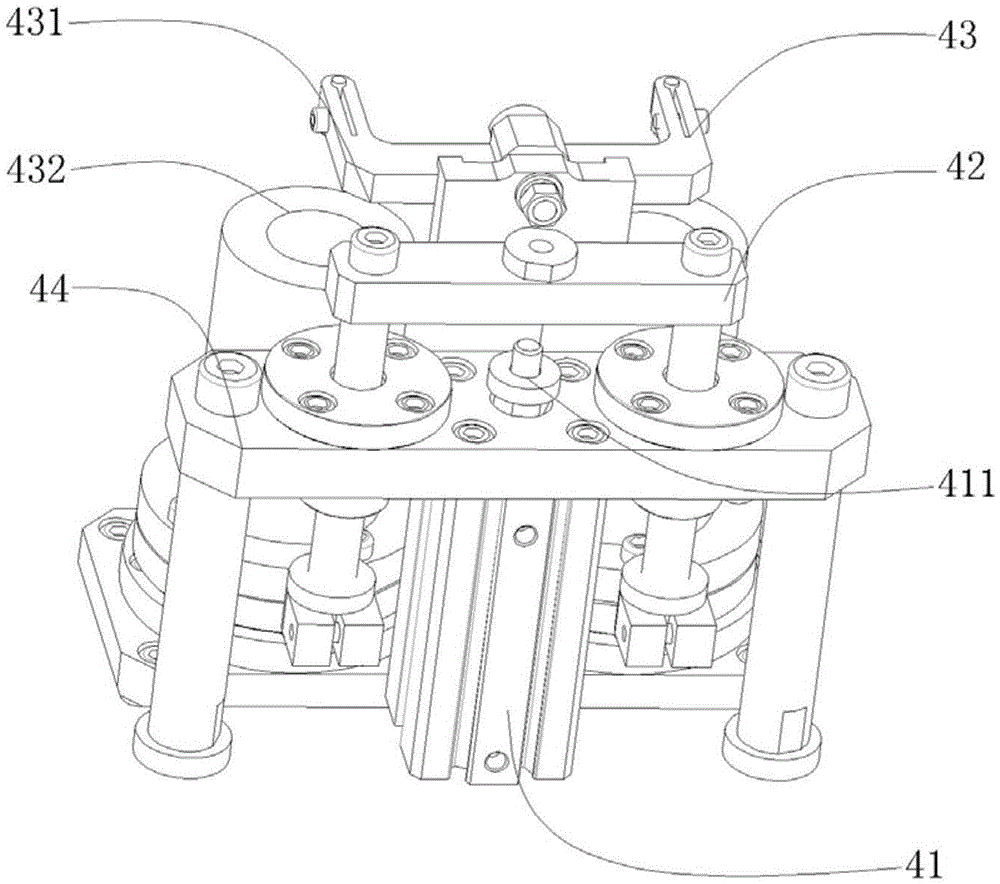

[0043] Such as Figure 1-9 As shown, the automatic patch welding and bending equipment for conductive sheets includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed, and the feeding device 2 includes a clamping device 14, a conveyor belt 1 12. The end of the conveyor belt 12 is provided with a tray 13; the discharge device 3 includes a clamping device 2 31 and a conveyor belt 2 32, and the middle part of the conveyor belt 2 32 is provided with a good product detector 321, and the good product detector After 321, a support frame 322 is also installed on one side of the conveyor belt 2 32, and a push cylinder 323 is installed on the support frame 322, and a push rod 324 is provided on the push cylinder 323, and the good product detector 321 is connected with the The above-described push cylinder 323 is electrically linked; the other side of the conveyor belt 2 32 is also provided with a slope 325, and the outlet end of the slope 3...

Embodiment 2

[0061] Such as Figure 1-9 As shown, the automatic patch welding and bending equipment for conductive sheets includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed, and the feeding device 2 includes a clamping device 14, a conveyor belt 1 12. The end of the conveyor belt 12 is provided with a tray 13; the discharge device 3 includes a clamping device 2 31 and a conveyor belt 2 32, and the middle part of the conveyor belt 2 32 is provided with a good product detector 321, and the good product detector After 321, a support frame 322 is also installed on one side of the conveyor belt 2 32, and a push cylinder 323 is installed on the support frame 322, and a push rod 324 is provided on the push cylinder 323, and the good product detector 321 is connected with the The above-described push cylinder 323 is electrically linked; the other side of the conveyor belt 2 32 is also provided with a slope 325, and the outlet end of the slope 3...

Embodiment 3

[0078] Such as Figure 1-10 As shown, the automatic patch welding and bending equipment for conductive sheets includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed, and the feeding device 2 includes a clamping device 14, a conveyor belt 1 12. The end of the conveyor belt 12 is provided with a tray 13; the discharge device 3 includes a clamping device 2 31 and a conveyor belt 32, and the front part of the conveyor belt 2 32 is provided with a deburring structure 327, and the deburring The structure 327 is pressed down by the lifting cylinder 328 to flatten the burrs on the solder of the conductive sheet; the middle part of the conveyor belt 2 32 is also provided with a good product detector 321, and the good product detector 321 is also installed on one side of the conveyor belt 2 32 There is a support frame 322, a push cylinder 323 is installed on the support frame 322, a push rod 324 is arranged on the push cylinder 323, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com