Multi-degree of freedom polishing workbench

A workbench and degree of freedom technology, applied in the direction of manufacturing tools, grinding racks, grinding bed, etc., can solve the problems of complex workpieces, heavy base weight of the workbench, inconvenient movement, etc., to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

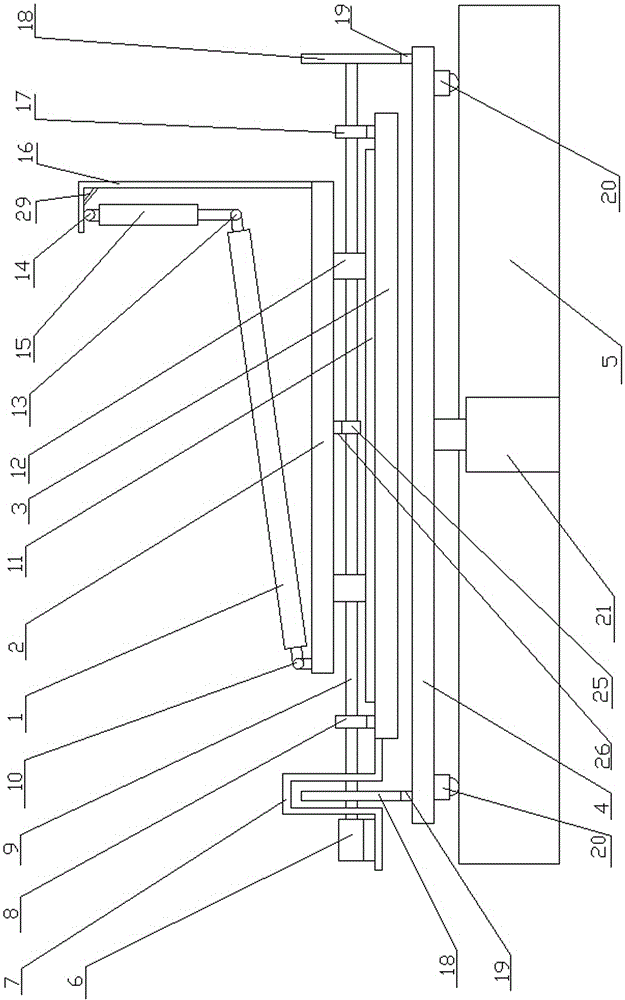

[0021] Combine below figure 1 The structure and working process of the present invention are further described.

[0022] A multi-degree-of-freedom grinding workbench of the present invention includes a workbench body 1 , and an upper load-bearing platform 2 is arranged below the workbench body 1 . The left end of the workbench body 1 is hinged to the upper load-bearing platform 2 through two hinge points, and the two hinge points are respectively referred to as the first hinge point 10 and the second hinge point (the second hinge point is not marked in the drawings ), and the first hinge point 10 and the second hinge point are arranged along the Y direction, and the connecting line between the first hinge point 10 and the second hinge point is parallel to the upper load-bearing platform 2 to ensure the stability of the working surface of the workbench body 1 . The right end of the workbench body 1 is connected with a cylinder 15, and a cylinder support frame 16 fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com