Resin-base composite material building template and manufacture method thereof

A technology of composite materials and building formwork, which is applied in the direction of building elements, chemical instruments and methods, lamination, etc., can solve the problems of high cost of aluminum formwork, affecting the surface of the wall, prone to deformation and depression, etc., to improve quality, Reduces the effect of felling, not easily deformed and dented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

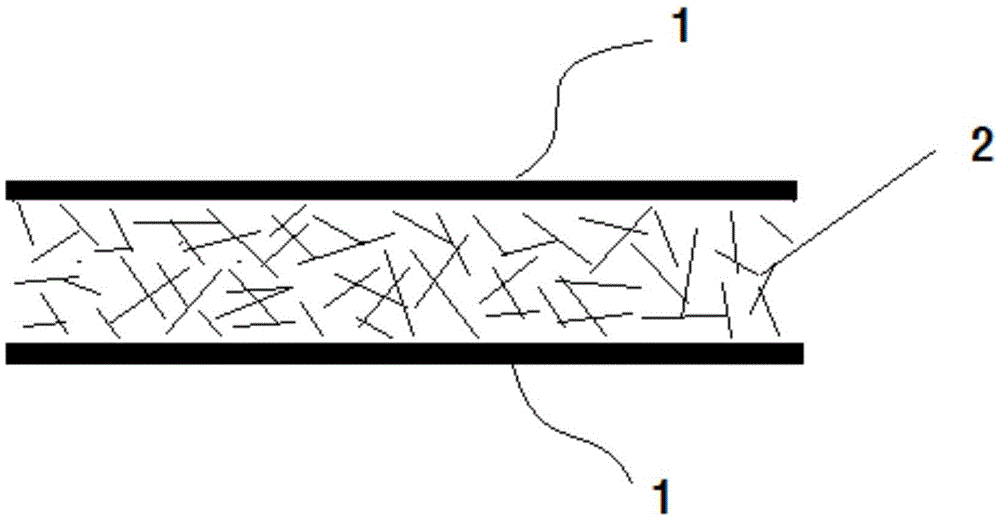

[0038] Such as figure 1 As shown, the resin-based composite building template includes two layers of continuous fiber-reinforced resin-based composite material layer 1 and one layer of long-fiber-reinforced resin-based composite material layer 2 . Two continuous fiber-reinforced resin-based composite material layers 1 are stacked on both sides of the long-fiber-reinforced resin-based composite material 2 respectively.

[0039]The continuous fiber reinforced resin-based composite material layer 1 includes continuous fibers and a first resin. The mass of the continuous fibers accounts for 20% of the total mass of the continuous fiber-reinforced resin-based composite material layer, and the mass of the first resin accounts for 80% of the total mass of the continuous fiber-reinforced resin-based composite material layer. Wherein, the aspect ratio of the continuous fiber is greater than 1000.

[0040] The long-fiber-reinforced resin-based composite material layer 2 includes long ...

Embodiment 2

[0055] The building formwork of resin-based composite material includes two layers of continuous fiber-reinforced resin-based composite material layer 1 and one layer of long-fiber-reinforced resin-based composite material layer 2 . Two continuous fiber-reinforced resin-based composite material layers 1 are stacked on both sides of the long-fiber-reinforced resin-based composite material 2 respectively.

[0056] The continuous fiber reinforced resin-based composite material layer 1 includes continuous fibers and a first resin. The mass of continuous fibers accounts for 40% of the total mass of the continuous fiber-reinforced resin-based composite material layer, and the mass of the first resin accounts for 60% of the total mass of the continuous fiber-reinforced resin-based composite material layer. Wherein, the aspect ratio of the continuous fiber is greater than 1000.

[0057] The long-fiber-reinforced resin-based composite material layer 2 includes long fibers and a second...

Embodiment 3

[0070] The building formwork of resin-based composite material includes two layers of continuous fiber-reinforced resin-based composite material layer 1 and one layer of long-fiber-reinforced resin-based composite material layer 2 . Two continuous fiber-reinforced resin-based composite material layers 1 are stacked on both sides of the long-fiber-reinforced resin-based composite material 2 respectively.

[0071]The continuous fiber reinforced resin-based composite material layer 1 includes continuous fibers and a first resin. The mass of continuous fibers accounts for 45% of the total mass of the continuous fiber-reinforced resin-based composite material layer, and the mass of the first resin accounts for 55% of the total mass of the continuous fiber-reinforced resin-based composite material layer. Wherein, the aspect ratio of the continuous fiber is greater than 1000.

[0072] The long-fiber-reinforced resin-based composite material layer 2 includes long fibers and a second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com