A New Wheel Tread Structure for High-speed EMUs

A technology for high-speed EMUs and wheel treads, applied to wheels, wheels characterized by track running parts, vehicle components, etc., can solve the problem of considering and balancing the dynamic performance of trains, the shape of wheel treads cannot be matched at the same time, and the repair cycle cannot be turned Improvement and other issues to achieve the effects of alleviating abnormal vehicle vibration, increasing the adaptability of vehicle suspension parameters, and improving the matching relationship between wheels and rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

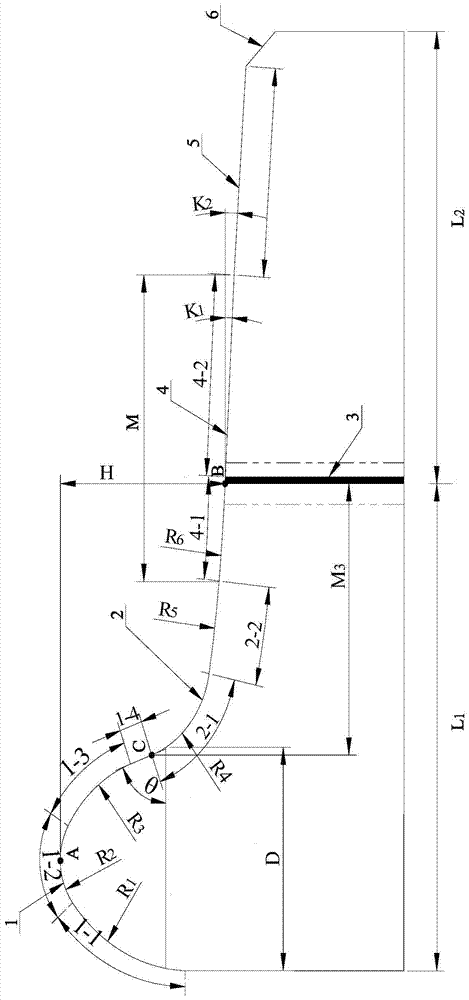

[0022] Such as figure 1 As shown, the new wheel tread structure of the high-speed EMU of the present invention includes a wheel rim 1, a throat root circle height taper area 2, a rolling circle 3, a normal working area 4, an outer end low taper area 5 and an outer end face chamfer area 6, It is characterized in that: the rim 1 includes the end face 1-1 of the first arc segment of the rim, the end face 1-2 of the second arc segment of the rim, the end face 1-3 of the third arc segment of the rim and the end face 1 of the straight segment of the rim -4, they are all smoothly connected in a tangent form sequentially. Throat root circular height taper zone 2 includes the end face 2-1 of the first circular arc segment in the throat root circular height taper zone and the end face 2-2 of the second circular arc segment in the throat root circular height taper zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com