Modified polyurethane resin and preparation method thereof

A polyurethane resin and modification technology, applied in the field of modified polyurethane resin and its preparation, can solve the problems of poor wear resistance and scratch resistance, affecting the wear resistance and scratch resistance of resin, achieve good wear and scratch resistance effect, and improve hydrolysis resistance. Sex, avoid the effect of needle explosion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

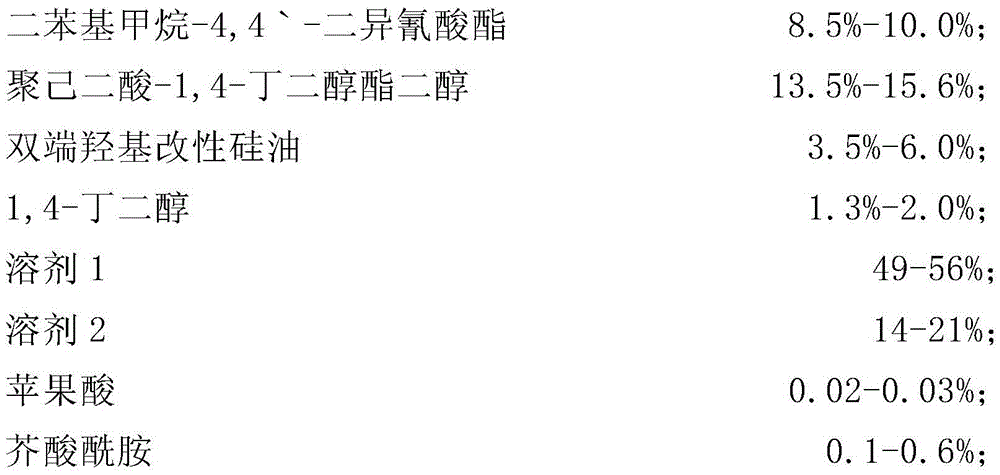

[0042] Group A allocation ratio

[0043]

[0044]

[0045] The number-average molecular weight of described two-terminal hydroxyl modified silicone oil (trade name is 2110, Shanghai Taige) is 1000,

[0046] The polyadipate-1,4-butylene glycol ester diol is self-produced by our company with a number average molecular weight of 1000 and named as PE-10.

[0047] Group B distribution ratio

[0048]

[0049] Described highly reactive polyether triol trade name is GEP330N, and molecular weight is 3000.

[0050] The polyadipate-based polyester polyol is a polyadipate-ethylene glycol-1,4-butylene glycol ester diol with a number average molecular weight of 2000 produced by our company, named PE-1.

[0051] The tetrahydrofuran-ethylene oxide copolyethylene glycol is DC-1800E with a number average molecular weight of 1800.

[0052] The preparation method of A component comprises the following steps:

[0053] (1) Put 42g of double-terminated hydroxyl modified silicone oil 211...

Embodiment 2

[0061] Group A allocation ratio

[0062] With the distribution ratio of group A in embodiment 1

[0063] Group B distribution ratio

[0064]

[0065]

[0066] The trade name of the highly active polyether triol is GEP330N, and its molecular weight is 3000.

[0067] The polyadipate-based polyester polyol is a polyadipate-1,4-butylene glycol ester diol with a number-average molecular weight of 2000 produced by our company, named as PE-6.

[0068] The tetrahydrofuran-ethylene oxide copolyethylene glycol is DC-1800E with a number average molecular weight of 1800.

[0069] The preparation method of A component: the same as the preparation method of A component in Example 1

[0070] The preparation method of component B: (1) put 69g high activity polyether triol GEP330N, 115gPE-1, 46gDC-1800E, 12.37g ethylene glycol and 447g N, N-dimethylformamide calculated according to the solid content of the reaction into After stirring and mixing in the reactor, add 55.5g of MDI50 to ...

Embodiment 3

[0074] Group A allocation ratio

[0075]

[0076]

[0077] The number-average molecular weight of described two-terminal hydroxyl modified silicone oil (trade name is 2110, Shanghai Taige) is 1000,

[0078] The polyadipate-1,4-butylene glycol ester diol is self-produced by our company with a number average molecular weight of 1000 and named as PE-10.

[0079] Group B distribution ratio

[0080] With the B component formula in embodiment 1

[0081] The preparation method of A component comprises the following steps:

[0082] (1) Put 63g of double-terminated hydroxyl modified silicone oil 2110 into the reaction kettle, stir and mix evenly, then add 33.1g of diphenylmethane-4,4'-diisocyanate to start the reaction, the reaction temperature is 70°C-80°C, The solid content of the reaction is 100%, NCO / OH=2.1, the NCO content is tested after 2 hours of reaction time, and after reaching the theoretical value, start the second step of reaction;

[0083](2) Add 378g N,N-dimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap