A kind of preparation method of antibacterial protective film and antibacterial protective film

A protective film and silver salt technology, applied in the direction of film/sheet adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of inability to achieve antibacterial effect, affect the light transmittance of the protective film, Problems such as inability to be precisely controlled, to achieve the effect of less entanglement and agglomeration of silver wires, guaranteed bactericidal performance, and large contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

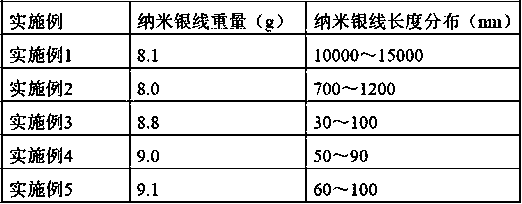

Embodiment 1

[0031] Example 1 is to prepare nano-silver structure solution: dissolve 0.1mol of silver nitrate and 0.08mol of polyvinylpyrrolidone in 22mol of ethylene glycol, stir at room temperature for 10min, heat up to 150°C, and keep warm for 30min to prepare nano-silver structure solution. Nano-silver structure solution of silver wire;

[0032] Specifically, the silver salt may include silver nitrate, silver trifluoromethanesulfonate, fatty acid silver salt (silver acetate), aromatic carboxylic acid silver salt or triazole organic silver salt.

[0033] The stabilizer is an organic polymer stabilizer, such as polyvinylpyrrolidone, polyethylene glycol, polyvinyl alcohol; it can also be a small molecule surfactant, such as oleic acid, cetyltrimethylammonium bromide, lauryl Sodium alkylsulfate, sodium dodecylbenzenesulfonate; it can also be the mixture of the above-mentioned organic polymer stabilizer and small molecule surfactant.

[0034] Polyols have dual functions as reactants and solv...

Embodiment 2

[0036] The difference between Example 2 and Example 1 is that the raw materials of the preparation method of Example 2 also include 0.0005 mol of imidazole-type ionic liquid, and the imidazole-type ionic liquid is added to ethylene glycol together with silver nitrate and polyvinylpyrrolidone. The imidazole-type ionic liquid is 1-methylimidazolium-3-propylsulfonate.

[0037] Imidazole-type ionic liquids equivalent to 1-methylimidazole-3-propylsulfonate can also choose 1-methylimidazole-3-butylsulfonate, 1-n-butyl-3-methylimidazole tetra Fluoroborate, 1-alkyl-3-methylimidazole bromide, N-methylimidazole p-toluenesulfonate.

Embodiment 3

[0039] The difference between Example 3 and Example 2 is that the composition of reactants in S1 is 0.1 mol of silver nitrate, 0.1 mol of polyvinylpyrrolidone, 20 mol of ethylene glycol, and 0.001 mol of imidazole-type ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com