Oil casing pipe communicating device for separate-layer fracturing string

A technology of layered fracturing and oil casing, which is applied in the direction of casing, drill pipe, wellbore/well valve device, etc. It can solve the problems of inconvenient construction, eruption and lifting of the pipe string, environmental pollution, etc., and achieve convenience Operational construction, significant economic and social benefits, and the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

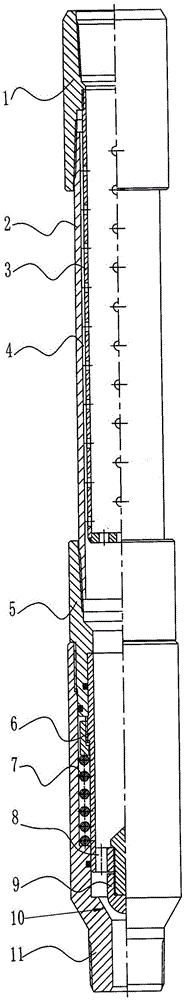

[0008] Attached below figure 1 Embodiments of the present invention will be described.

[0009] As can be seen from the figure, the embodiment of the present invention includes a connecting head 5, a sliding sleeve 6, a spring 7, a valve core 9, and a valve body 11. The upper end of the sliding sleeve 6 rests on the shoulder inside the connecting head 5, so that the sliding sleeve 6 is limited position, the spring 7 is sleeved on the sliding sleeve 6, the upper end surface of the spring 7 is supported on the outer shoulder of the sliding sleeve 6, the valve core 9 is installed in the middle position of the bottom of the sliding sleeve 6, the bottom surface of the sliding sleeve 6 has a communication hole 8, the valve The upper part of the body 11 is connected with the lower part of the connecting head 5, so that the lower end face of the spring 7 is supported on the inner shoulder of the valve body 11, and there is a valve port 10 in the lower part of the valve body 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com