Anti-torsion and even-abrasion heading machine

A roadheader and anti-torsion technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of reducing the use efficiency of roadheaders, increasing maintenance time, and inconsistent time for replacing cutters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

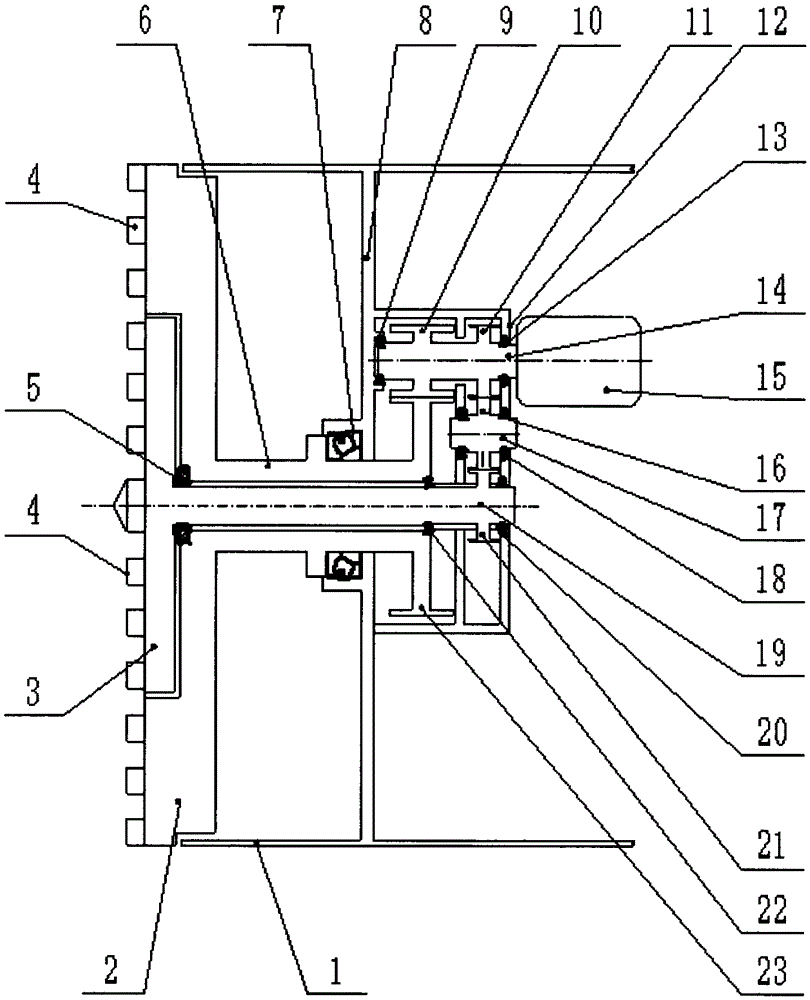

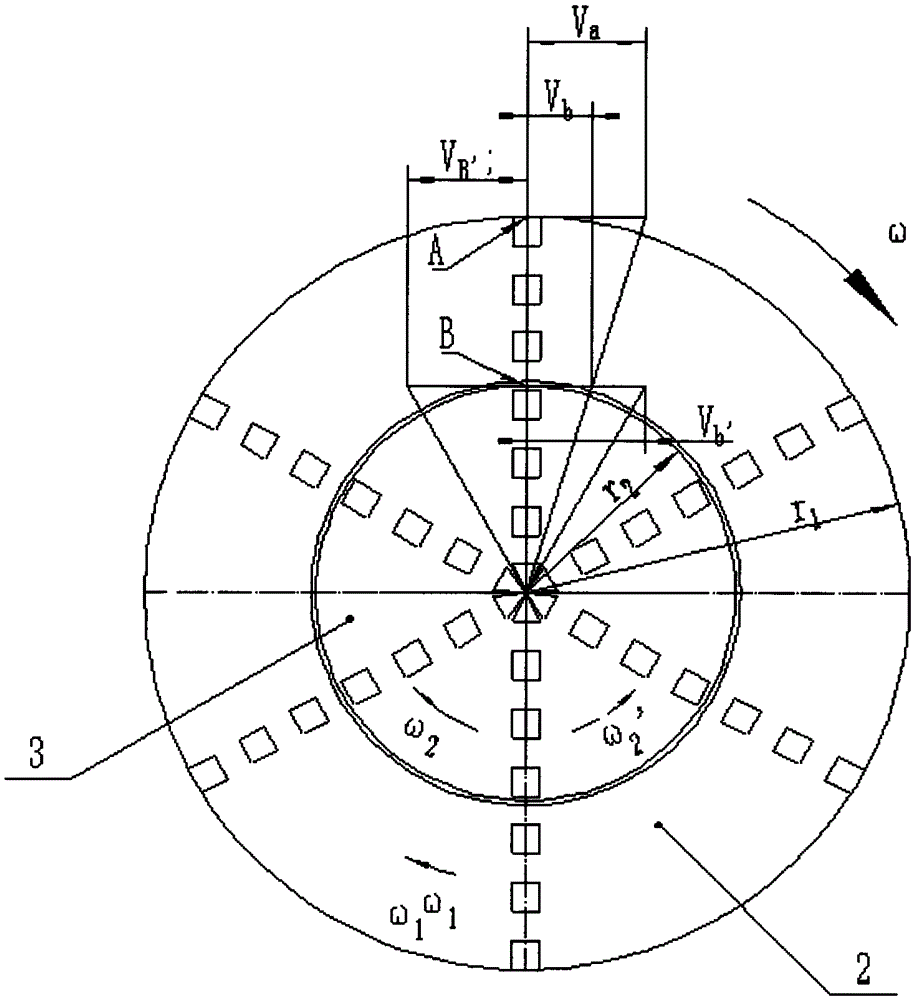

[0007] Such as figure 1 Shown: the present invention includes the hollow shaft 6 that is arranged in the casing cylinder 1 of the roadheader, the rear portion of the hollow shaft 6 is connected with the gear box 12 and the motor 15 , and the front portion of the hollow shaft 6 is fixedly connected with the outer cutter head 2 . The power of the motor 15 drives the gear 10 through the input shaft 14 in the gearbox 12, meshes with the gear 23 on the hollow shaft 6, drives the hollow shaft 6 to rotate, and drives the outer cutter head 2 to rotate, and the cutter on the outer cutter head 2 4. Cut the rock and soil on the peripheral part of the face.

[0008] Inside the hollow shaft 6, a central shaft 19 is interspersed, its rear part is connected with the gear box 12 and the motor 15, and the front part of the central shaft 19 is fixedly connected with the inner cutterhead 3. Gear box 12 li is provided with intermediate shaft 17, and idler gear 16 is housed on it. The power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com