Multi-range Powershift Parallel Hybrid Transmission

A power shift and hybrid technology, applied in transmissions, gear transmissions, belts/chains/gears, etc., can solve problems such as power interruption, difficulty in realizing hybrid functions, and affecting vehicle dynamics, achieving easy control, The effect of shortening shift time and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

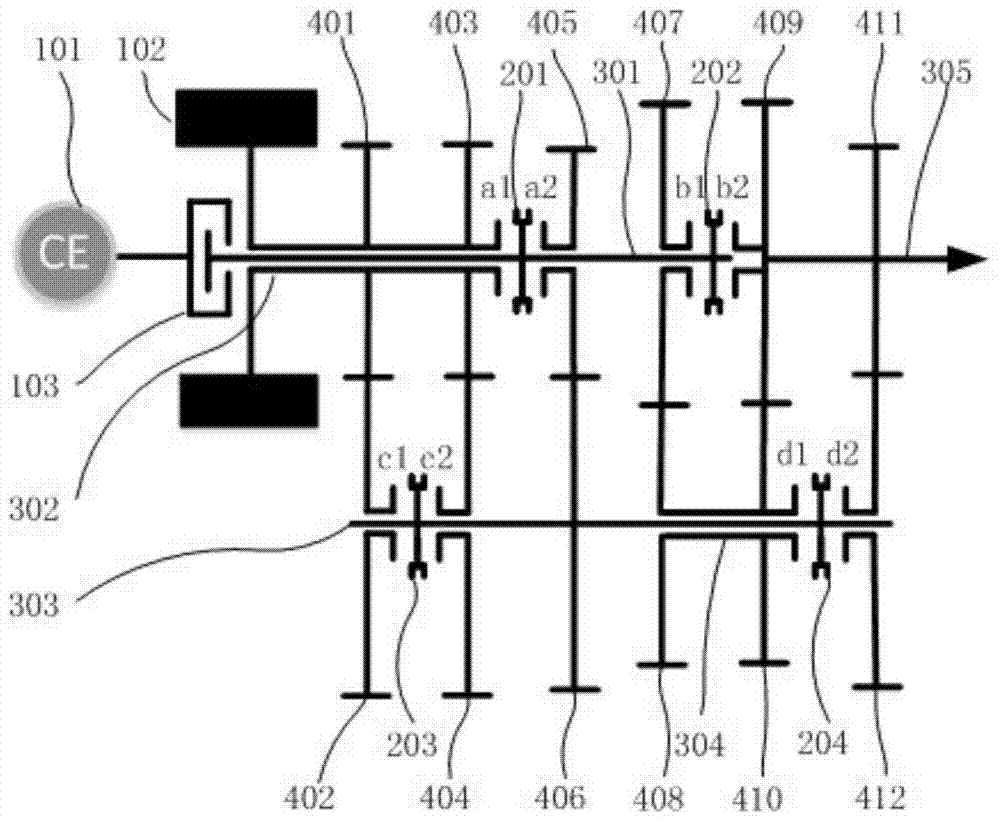

[0037] see figure 1 , a multi-gear power shift parallel hybrid transmission, which includes: an engine input shaft 301, a motor power input shaft 302, an intermediate shaft 303, a sleeve shaft 304, a transmission output shaft 305, a first synchronizer 201, a second Second synchronizer 202, third synchronizer 203, fourth synchronizer 204, first gear 401, second gear 402, third gear 403, fourth gear 404, fifth gear 405, sixth gear 406, seventh gear 407, eighth gear 408, ninth gear 409, tenth gear 410, eleventh gear 411, twelfth gear 412;

[0038] The engine input shaft 301, the motor power input shaft 302 and the gearbox output shaft 305 are coaxially arranged;

[0039] A sleeve shaft 304 is arranged on the intermediate shaft 303, which is arranged in parallel with the engine input shaft 301;

[0040] The first synchronizer 201 and the second synchronizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com