An anti-overload transmission device for a power output shaft

A technology for power output shafts and transmissions, which is applied to transmissions, belts/chains/gears, mechanical equipment, etc., and can solve problems such as transmission shaft damage, overload, and drive motor burnout due to overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

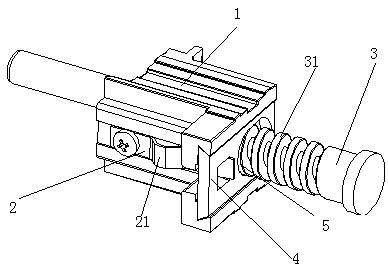

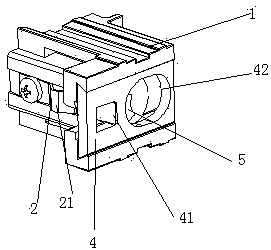

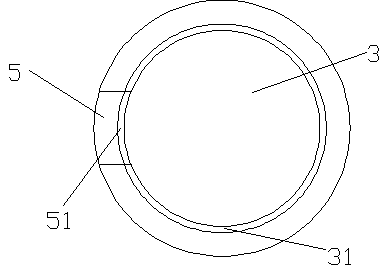

[0018] Such as figure 1 , figure 2 , Figure 4 As shown, the present invention provides a transmission device that prevents the drive shaft from being able to stop the transmission when an overload occurs. The device is mainly composed of a transmission block 1, a transmission shaft 3, a sensing slider 4 and a reed 2. An external thread 31 is provided on the transmission shaft 3, and a chute is provided on the front end of the transmission block 1. In this embodiment The chute in is set as a dovetail slot. At the same time, the chute can also be set as a T-shaped slot. When it is set as a T-shaped slot, the corresponding sides of the sensing slider are bosses that match the T-shaped slot. The slider is slidably arranged in the T-shaped slot through the boss. The corresponding two sides of the sensing slider 4 are slopes compatible with the dovetail groove, the sensing slider 4 is slidably arranged in the dovetail groove through the slope, and a transmission shaft with a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com