Method for preparing high-performance material by functionalization of two-dimensional material CaGeTe

A two-dimensional material and functionalization technology, applied in chemical instruments and methods, inorganic chemistry, germanium compounds, etc., can solve problems such as difficult functionalization of GeTe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

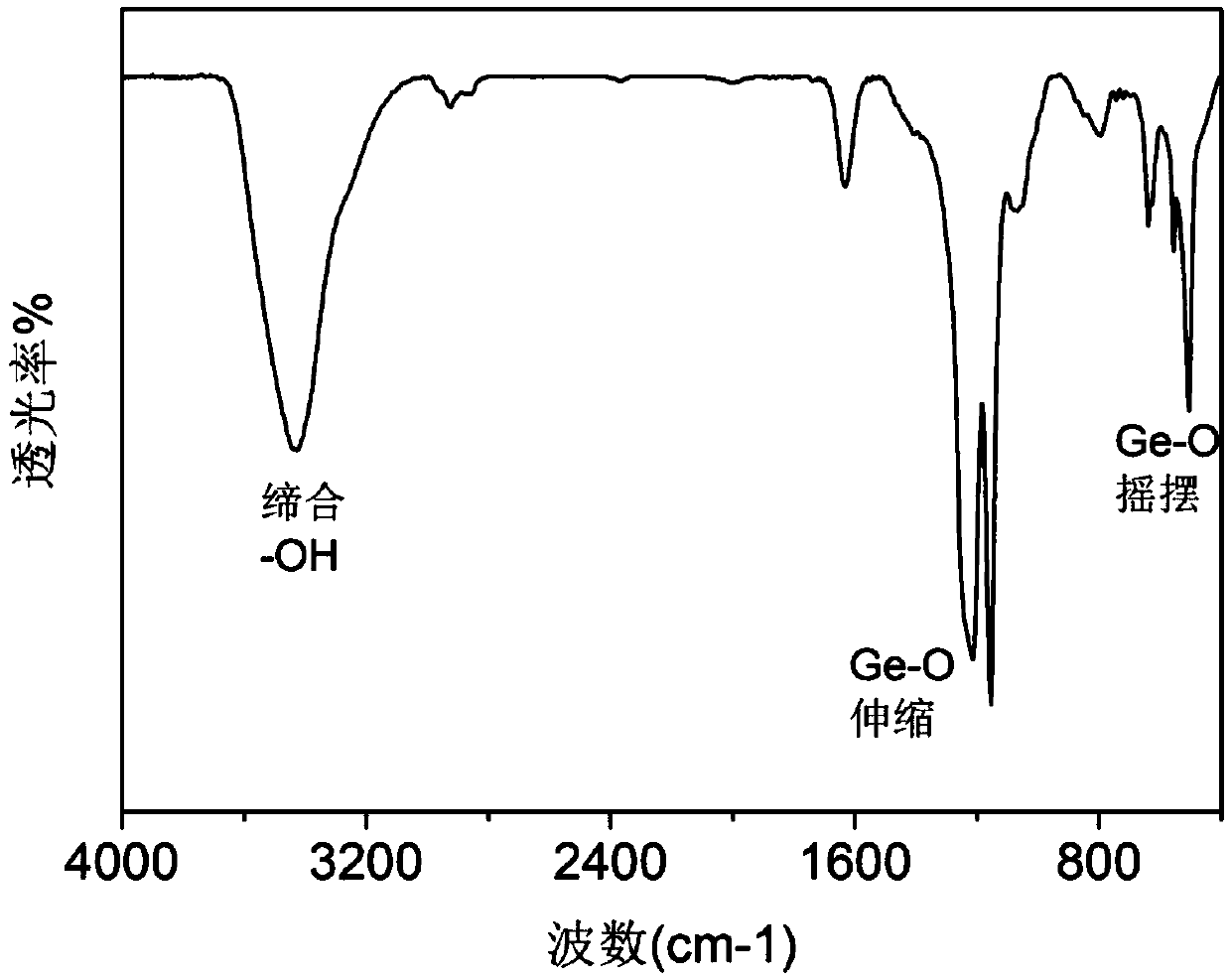

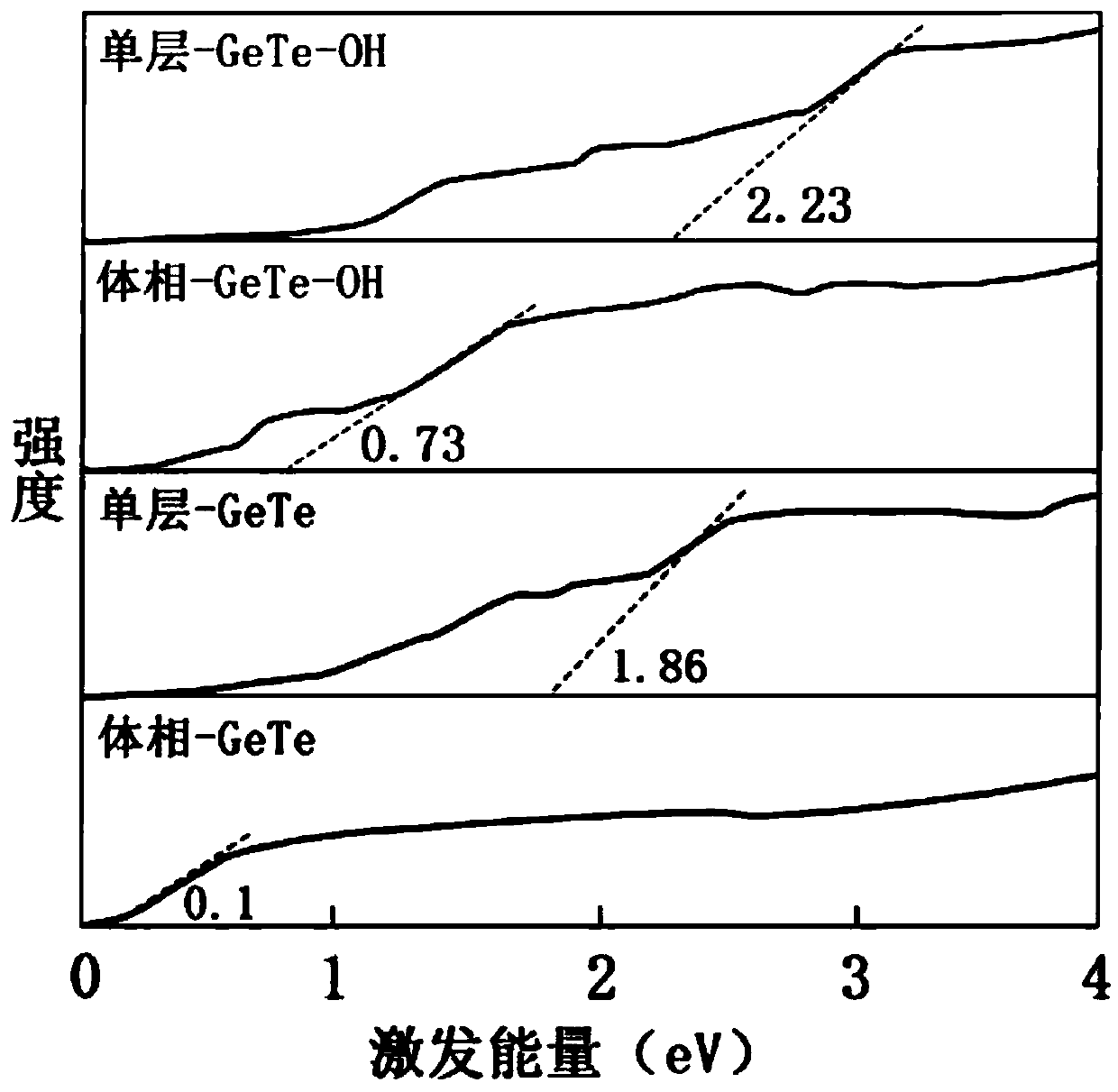

[0025] Weigh 10mmolCa, 10mmolGe, and 11mmolTe in the glove box in turn, put them in the packaged quartz tube, and sinter them in a CVD tube furnace under vacuum. Rise from room temperature to 1050°C in 400min, maintain for 1200min, then cool down to 800°C in 1200min, and then slowly lower the temperature at 0.5°C / min. To room temperature, wash with toluene and ethanol in turn, after drying, add a magnetic stirrer, 15ml deionized water, 2ml acetonitrile, 60mg CaGeTe precursor, 3ml iodoethanol, and stir and seal to avoid light for 3 days (24 hours a day). GeTe-OH is obtained. Disperse in a vial filled with ethanol, seal the mouth of the bottle with Teflon tape, sonicate for 2 hours to avoid overheating of the bathtub and liquid, maintain water cooling at 20°C, and centrifuge at 3000rmp to obtain the two-dimensional layered semiconductor material GeTe-OH.

example 2

[0027] Weigh 10mmolCa, 10mmolGe, 11mmolTe in the glove box in turn, put them in the packaged quartz tube, CVD tube furnace vacuum sintering, 300min from normal temperature to 1000℃, maintain 1500min, then cool down to 900min in 1000min, and then slowly lower the temperature at 0.5℃ / min To room temperature, wash with toluene and ethanol in turn, after drying, add a magnetic stirrer, 20ml deionized water, 5ml acetonitrile, 100mg CaGeTe precursor, 5ml bromoethanol, stir and seal for 50 hours in the dark to obtain GeTe-OH. Disperse in a vial filled with ethanol, seal the mouth of the bottle with Teflon tape, ultrasonically treat for 5 hours, avoid overheating of the bathtub and liquid, maintain water cooling at 20°C, and centrifuge at 3000rmp to obtain the two-dimensional layered semiconductor material GeTe-OH.

example 3

[0029] Weigh 10mmolCa, 10mmolGe, 11mmolTe in the glove box in turn, put them in the packaged quartz tube, CVD tube furnace vacuum sintering, 400min from room temperature to 1100°C, maintain 1000min, then cool down to 850°C in 1100min, then slowly at 0.1°C / min Cool down to room temperature, rinse with toluene and ethanol in turn, and after drying, add a magnetic stirrer, 10ml deionized water, 1ml acetonitrile, 50mg CaGeTe precursor, 1ml 3-iodopropanol, and stir for 100 hours to obtain GeTe -OH. Disperse in a vial filled with ethanol, seal the bottle mouth with Teflon tape, ultrasonically treat for 1 hour, avoid overheating of the bathtub and liquid, maintain water cooling at 20°C, and centrifuge at 5000rmp to obtain the two-dimensional layered semiconductor material GeTe-OH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com