Surveillance camera

A monitoring camera and camera technology, applied in the field of monitoring cameras, can solve problems such as waste of resources, inconvenient adjustment, and waste, and achieve the effects of resource and cost saving, convenient adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

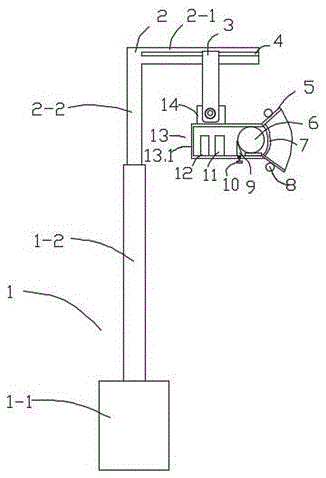

[0021] Such as figure 1 As shown, this embodiment provides a surveillance camera, including a camera body 13 and a mounting bracket 2, characterized in that a hydraulic lifting device 1 is connected under the mounting bracket 2, and the hydraulic lifting device 1 includes a hydraulic adjustment cylinder 1-1 And the hydraulic adjustment rod 1-2, the two ends of the hydraulic adjustment rod 1-2 are respectively connected to the hydraulic adjustment cylinder 1-1 and the installation bracket 2, the installation bracket 2 includes an integrally formed horizontal support plate 2-1 and a vertical support Plate 2-2, the vertical support plate 2-2 is connected with the top end of the hydraulic adjustment rod 1-2, the transverse support plate 2-1 is provided with a chute 4, the shape of the cross section of the chute 4 is a non-return Groove, chute 4 is clamped with camera fixing device 3, and camera fixing device 3 can move back and forth along chute 4, and the other end of camera fixi...

Embodiment 2

[0023] This embodiment is further improved on the basis of embodiment 1, specifically,

[0024] The pixel of the monitoring camera is not less than 250,000.

[0025] Described lighting lamp 8 is 6.

[0026] The inner wall of the camera installation box 13.1 is provided with an interference signal shielding layer.

[0027] The rear of the camera 6 in the camera installation box 13.1 is provided with a focus adjustment block 9, the focus adjustment block 9 is a wedge-shaped structure, and the wedge-shaped surface of the focus adjustment block 9 is arranged directly behind the camera 6. The bottom of the focal length adjustment block 9 is connected with an adjusting bolt 10 passing through the camera installation box 13.1, a sealing ring is arranged between the camera protection glass 7 and the camera installation box 13.1, and the adjustment bolt 10 is installed with the camera installation box 13.1. The boxes 13.1 are hermetically connected by connecting bearings.

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com