A milling and air conditioning system combined with waste heat utilization and a milling and air conditioning method

A technology for air regulation and waste heat, which is applied in combustion methods, lighting and heating equipment, block/powder fuel preparation, etc. It can solve the problem of decreased coal drying capacity, prolonged transition period of auxiliary fuel combustion, and increased pollution of denitration catalysts and dust collectors. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

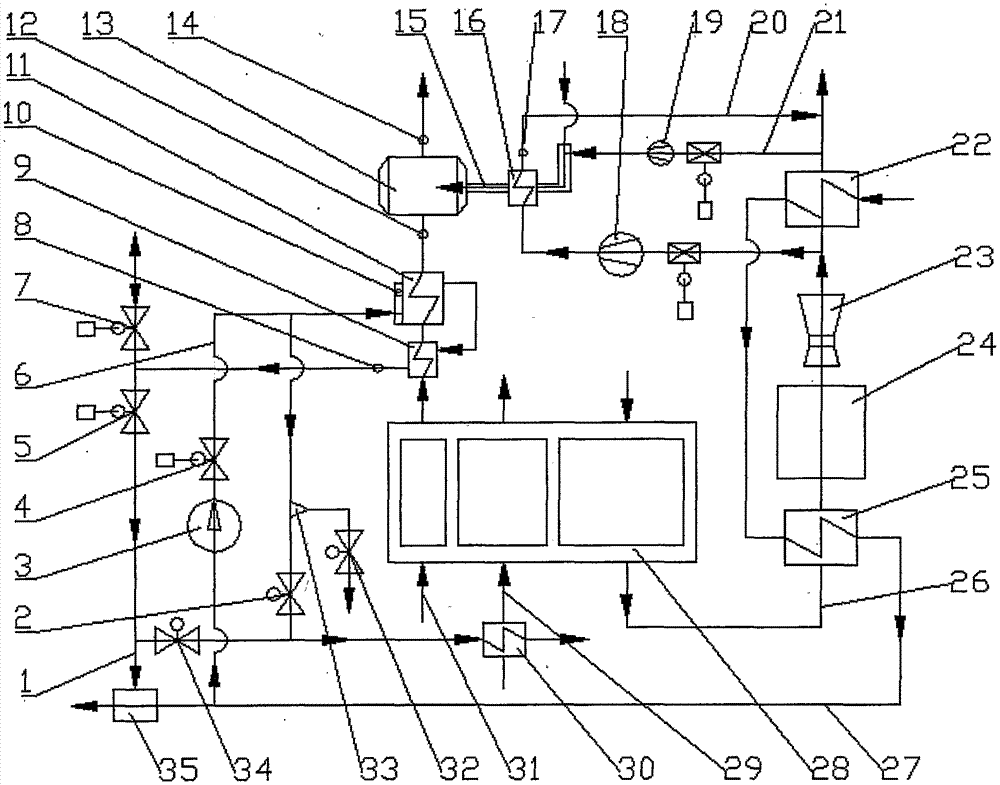

[0110] This embodiment provides a pulverizing air conditioning system combined with waste heat utilization, the specific connection relationship is as follows figure 1 As shown, the pulverizing air conditioning system combined with waste heat utilization includes: air preheater 28, pre-empty air supply heater 30, hot primary air phase change cooler 11, coal mill 13, dust collector 24, induced draft fan 23 And condensed water low temperature heater 22;

[0111] The heat medium inlet of the air preheater 28 communicates with the flue 26, and the heat medium outlet of the air preheater 28 communicates with the dust remover 24 inlet; the first refrigerant inlet and the second refrigerant of the air preheater 28 The refrigerant inlet communicates with the primary air duct and the refrigerant outlet of the air preheater 30 respectively; the first refrigerant outlet of the air preheater 28 communicates with the heat medium inlet of the hot primary air phase change cooler 11, and the ...

Embodiment 2

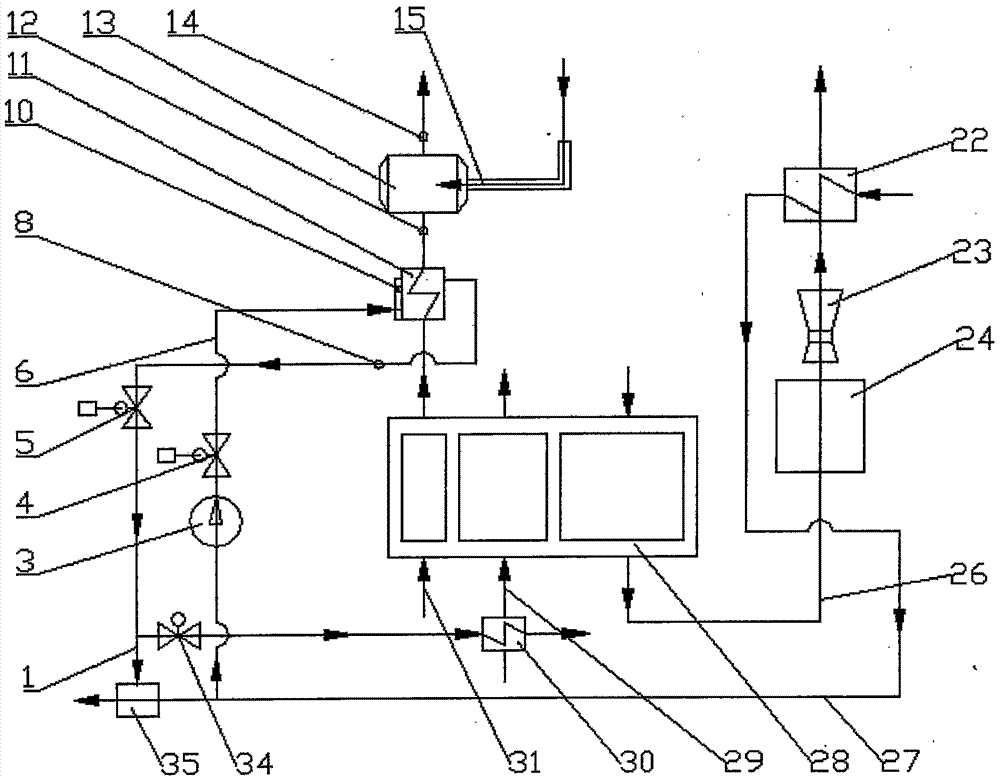

[0128] This embodiment provides a pulverizing air regulating system combined with waste heat utilization, and its specific structure is as follows figure 2 As shown, the air conditioning system for milling milling combined with waste heat utilization in this embodiment is basically the same as that of Embodiment 1, the difference is that the air conditioning system for milling milling combined with waste heat utilization in this embodiment also includes a superheater 9, and the air is preheated The first refrigerant outlet of the device 28 communicates with the heat medium inlet of the superheater 9, and the heat medium outlet of the superheater 9 communicates with the heat medium inlet of the hot primary air phase change cooler 11, and the hot primary air phase change cooler 11 The refrigerant outlet of the superheater 9 communicates with the refrigerant inlet of the superheater 9, and the refrigerant outlet of the superheater 9 is connected with the heat medium inlet of the ...

Embodiment 3

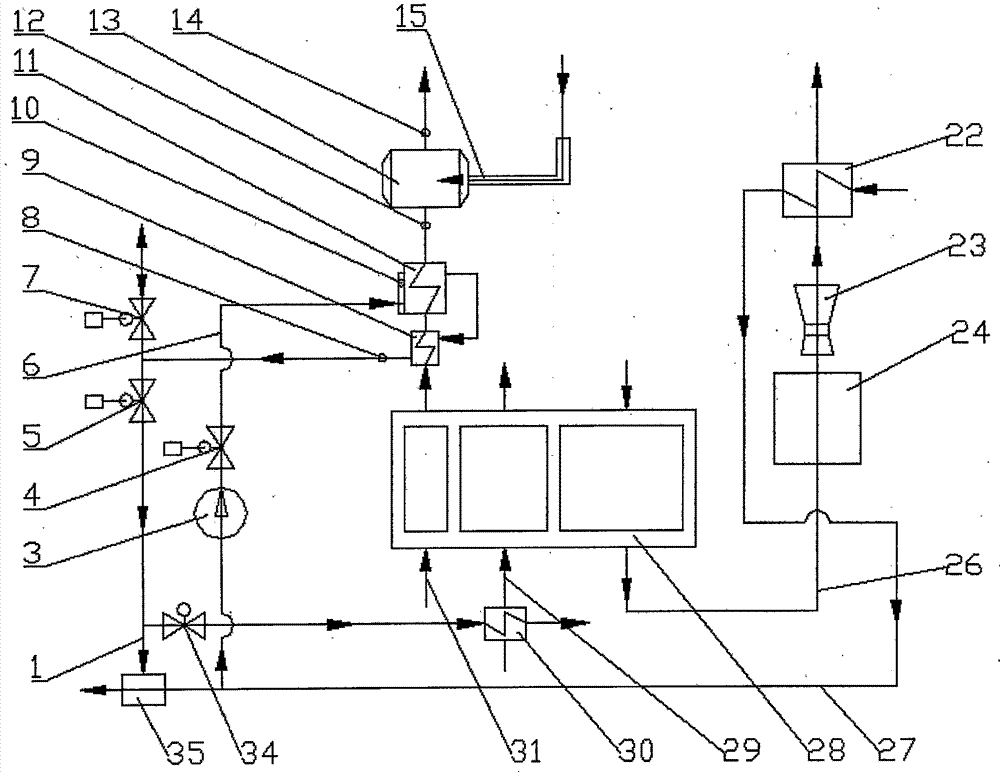

[0134] This embodiment provides a pulverizing air regulating system combined with waste heat utilization, and its specific structure is as follows image 3 As shown, the powder-making air conditioning system combined with waste heat utilization in this embodiment is basically the same as that in Embodiment 2, the difference is that the refrigerant outlet of the condensed water low-temperature heater 22 and the refrigerant of the hot primary air phase change cooler 11 in this embodiment The pipeline between the inlets is a variable-diameter pipe, and the diameter of a section of the pipe between the liquid flow regulating valve 4 and the hot primary air phase-change cooler 11 close to the hot primary air phase-change cooler 11 is larger than other pipe diameters; the combined waste heat utilization The pulverizing air conditioning system also includes a discharge pipe, one end of the discharge pipe is connected with a variable diameter pipe with a larger pipe diameter and close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com