Mechanical equipment assembly training method based on assembly interface

A training method and mechanical technology, which is applied in the field of mechanical equipment, can solve the problems of increasing the cost of mechanical equipment assembly training, poor effect, and out of assembly experience, etc., to overcome experience defects and behavior habit development defects, improve effects, and improve skills horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] First, the present invention will be further explained in conjunction with the drawings:

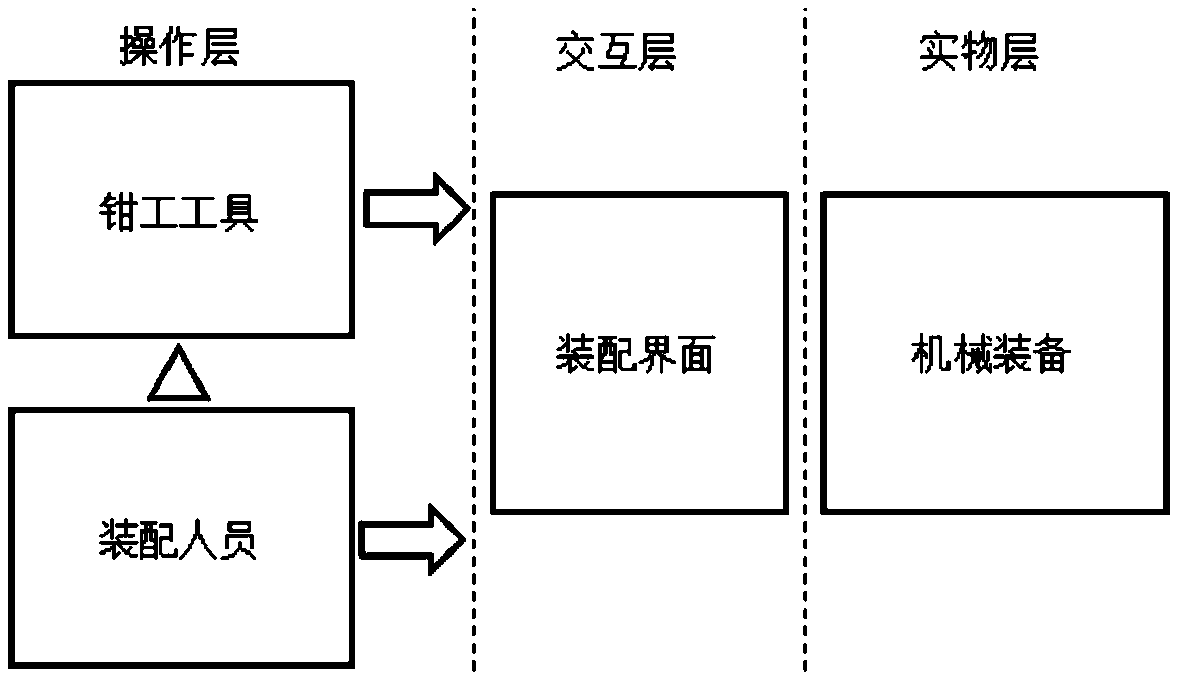

[0035] The invention is a mechanical equipment assembly training method based on an assembly interface, which can abstractly define a system composed of assembly personnel, assembly tools, relevant parts to be assembled and other components related to mechanical equipment assembly as a mechanical equipment assembly training system. Such as figure 1 As shown, in the assembly process of mechanical equipment, the parts or parts that directly receive and measure the assembly operation or the interaction surface of the parts and the personnel and tools are abstractly defined as the assembly interface.

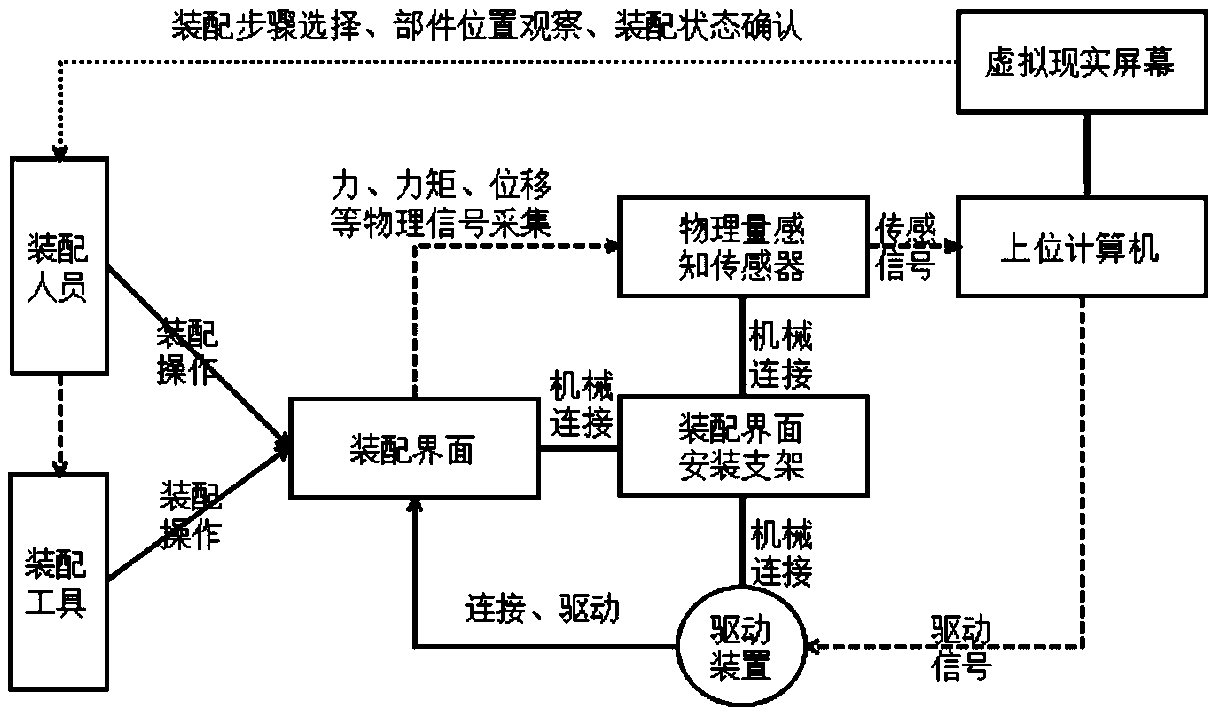

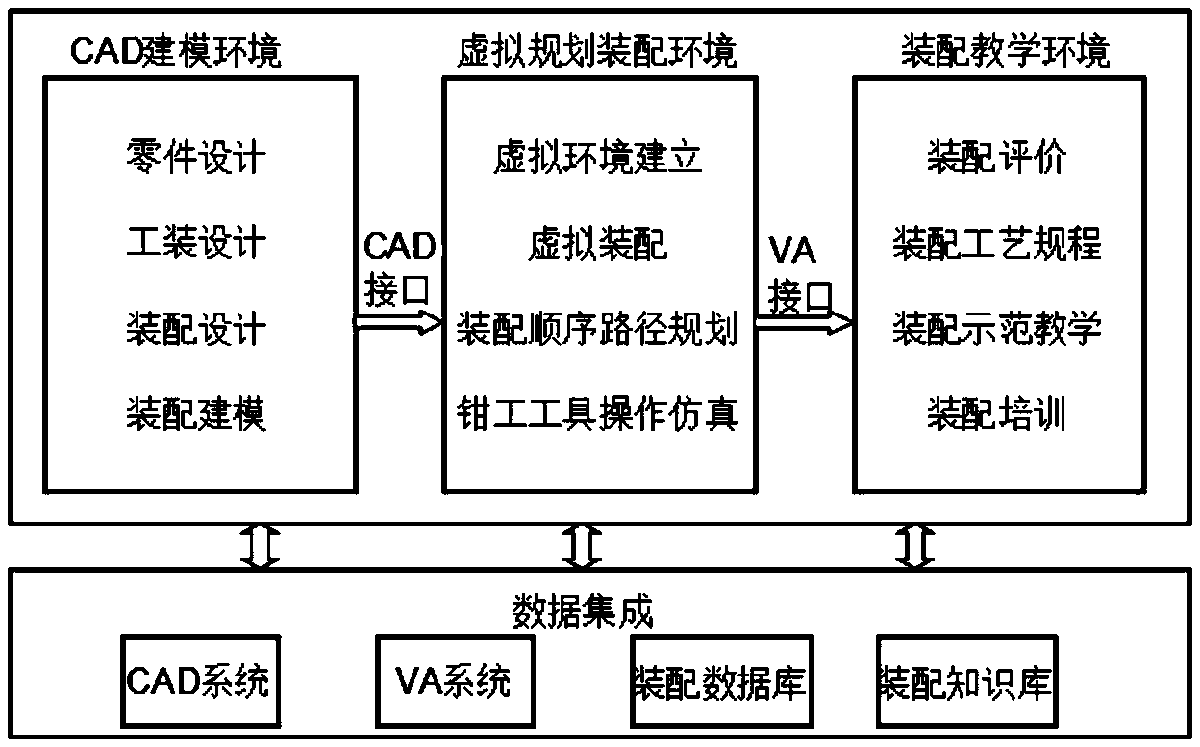

[0036] The trained workers complete the assembly procedure training, assembly tool use training and fitter process training of the mechanical equipment by combining the virtual assembly scene of the mechanical equipment with the actual assembly behavior; this method uses the virtual reality s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com