Steam power generation device, and modification method and operation method thereof

A technology for power generation equipment and steam, which is used in steam generation, mechanical equipment, steam application, etc., and can solve problems such as reducing the efficiency of turbine equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

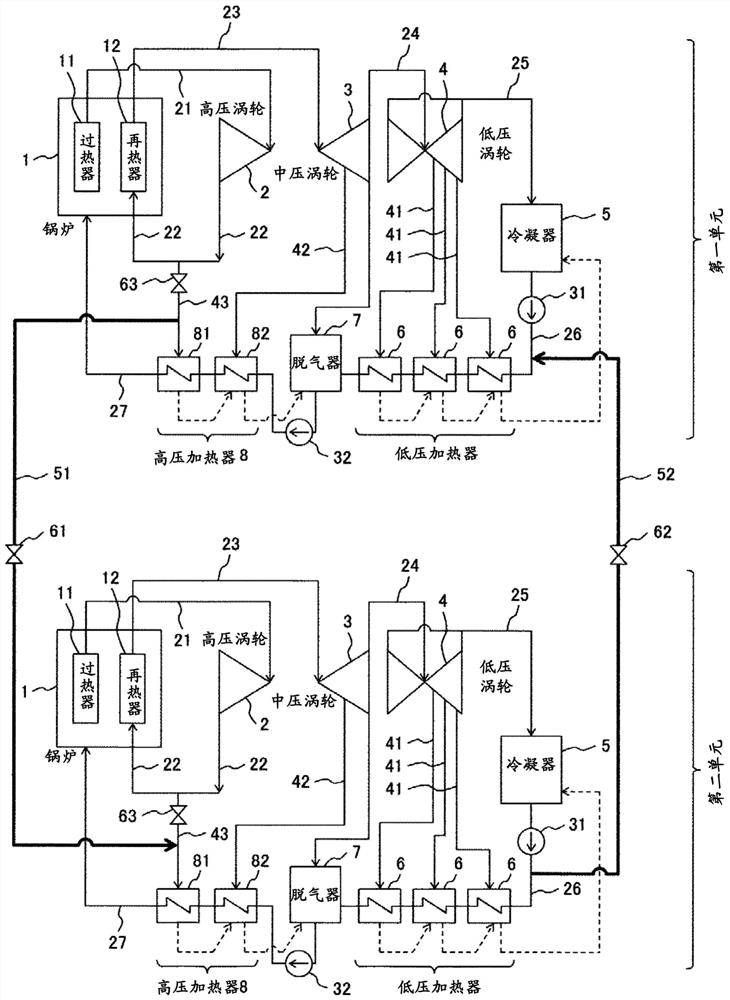

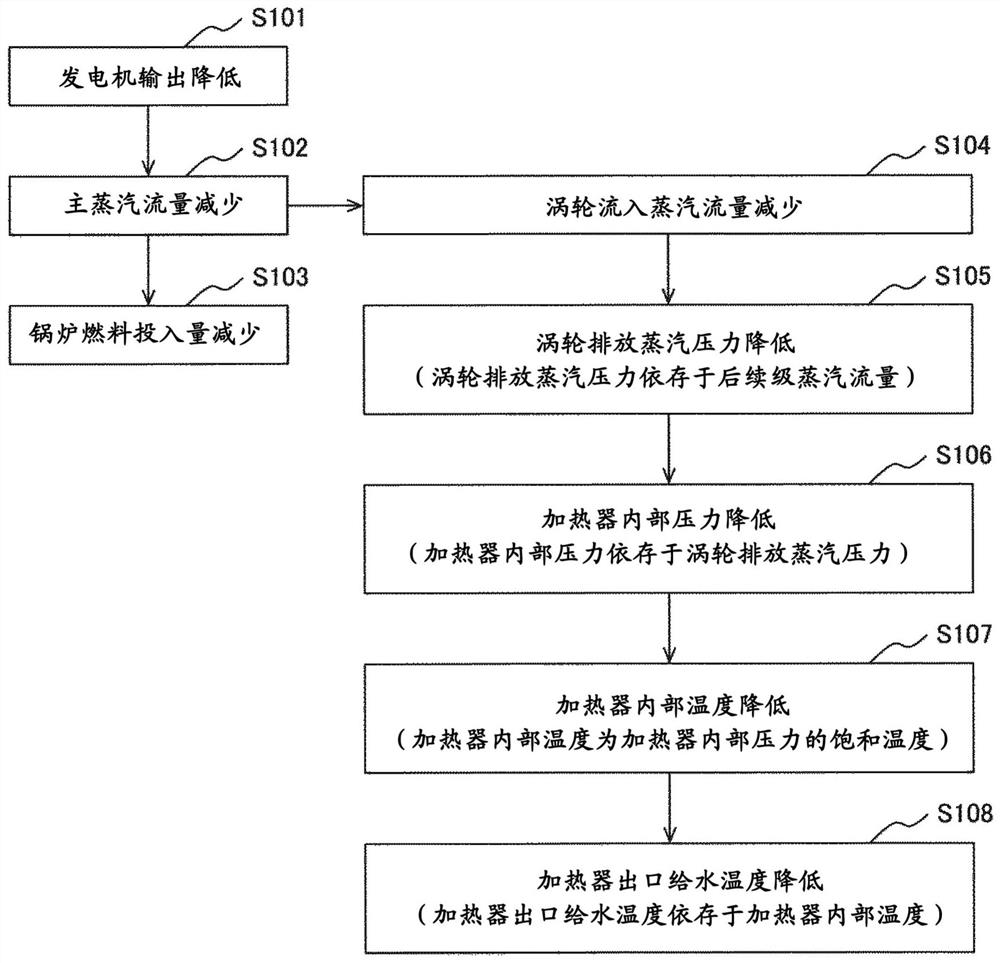

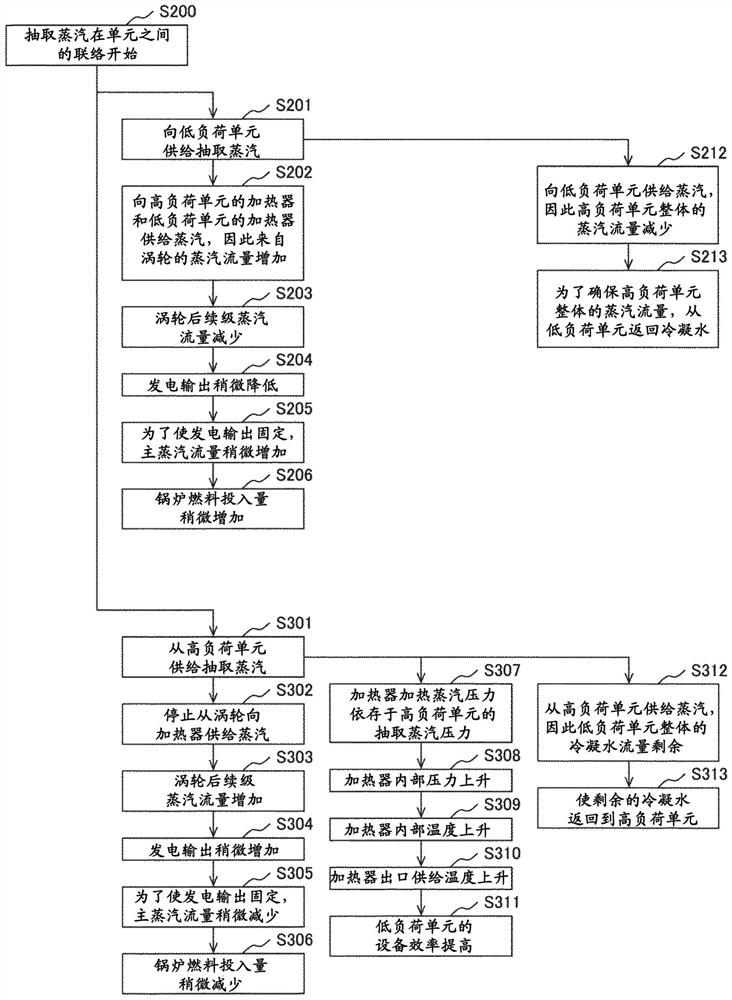

[0020] First, a schematic configuration of a steam power plant including a plurality of units described in this embodiment will be described.

[0021] figure 1 It is an explanatory drawing explaining the schematic structure of the steam power plant provided with the several units demonstrated in this Example.

[0022] The steam power generation facility described in this embodiment includes a boiler 1 for generating steam, a high-pressure steam turbine (high-pressure turbine) 2 driven by steam generated by the boiler 1, an intermediate-pressure steam turbine (intermediate-pressure turbine) 3, and a low-pressure steam turbine ( low pressure turbine) 4, condenser 5 to return steam to condensed water, degasser 7 to degas condensed water (remove dissolved gas (such as oxygen) from condensed water) and become feed water.

[0023] In addition, steam discharged from the intermediate-pressure turbine 3 is supplied to the deaerator 7 . This steam becomes feed water.

[0024] The boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com