A battery assembly for engineering vehicles

A technology for engineering vehicles and battery components, which is applied to battery pack components, vehicle components, electrical components, etc., which can solve the problems of difficulty in battery installation and positioning, poor flexibility, and danger, and achieve convenient and quick replacement and fixing, and improve use efficiency , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

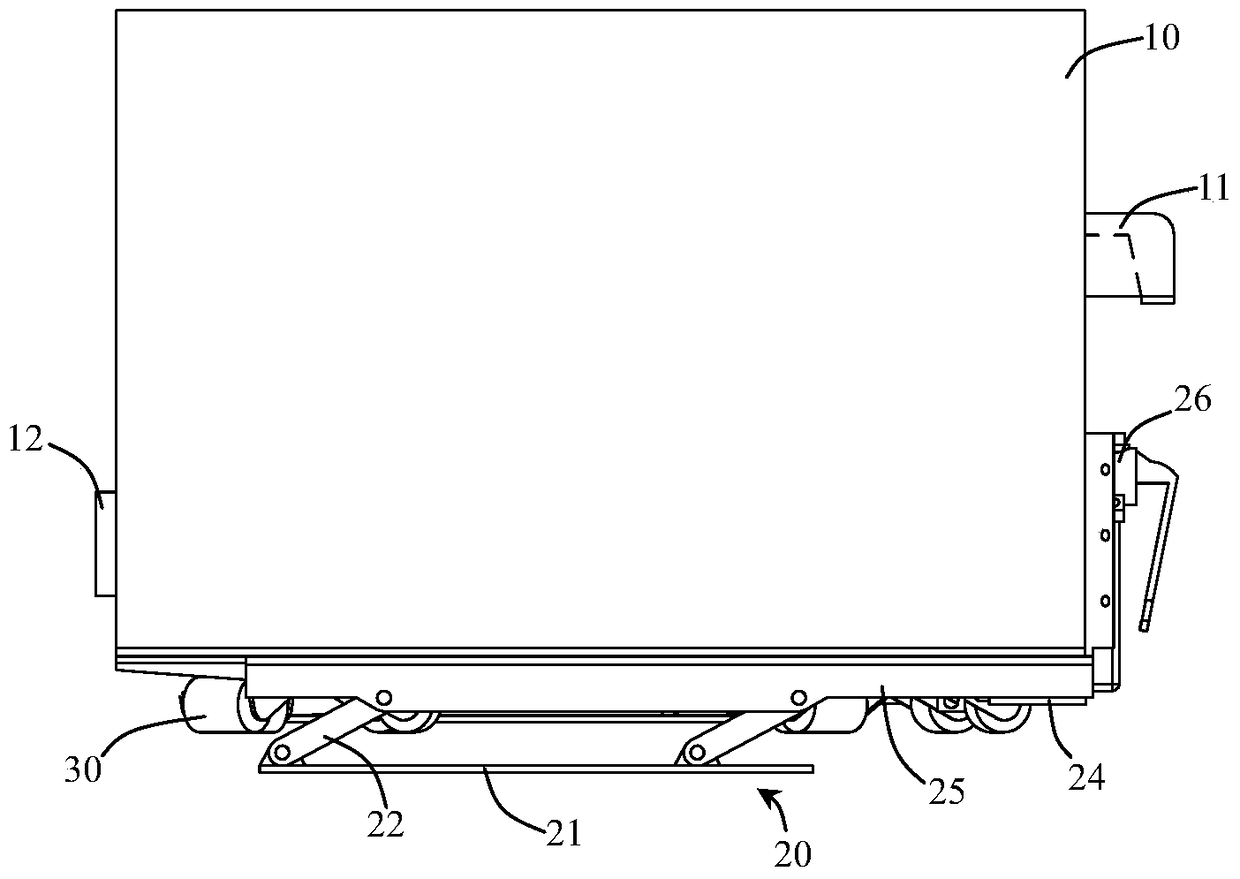

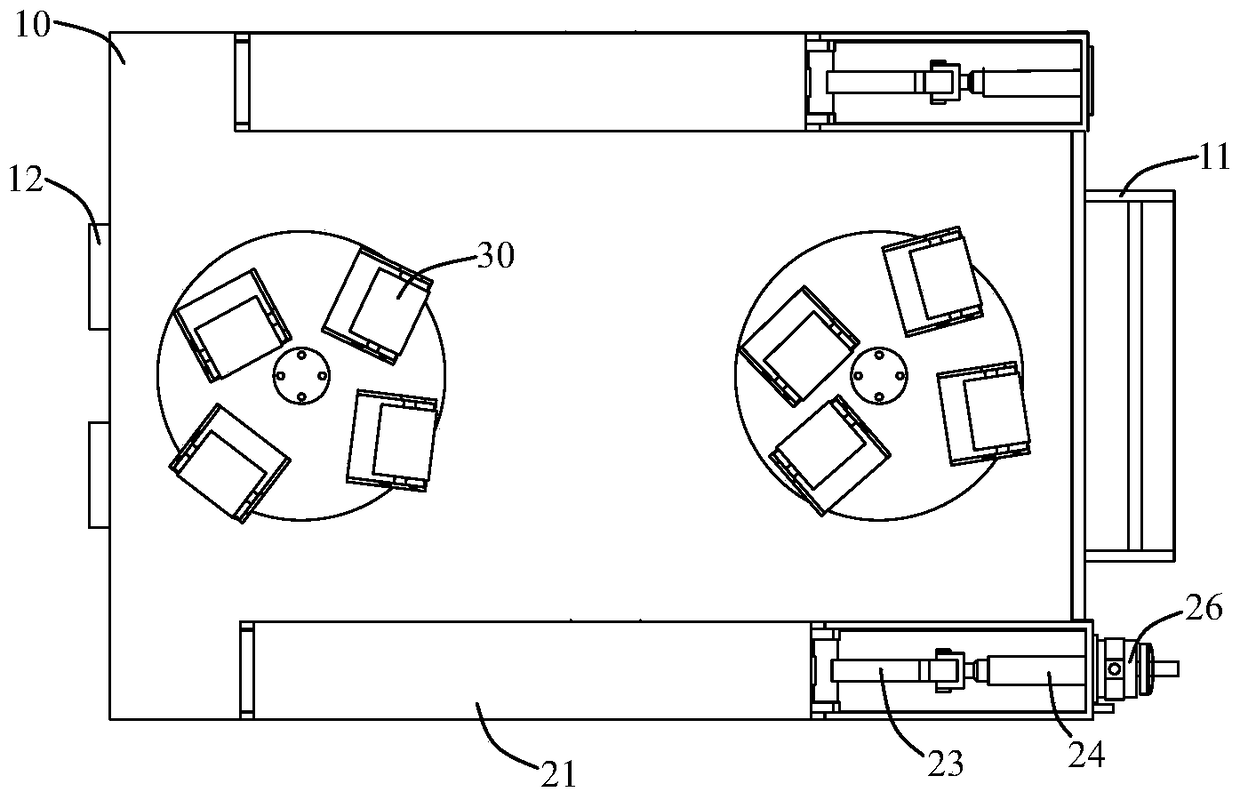

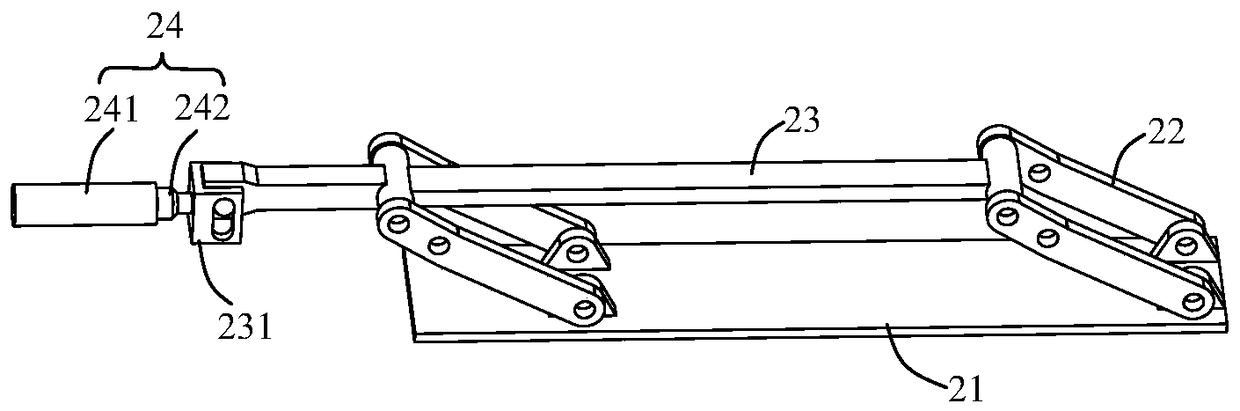

[0030] Such as Figure 1~6 Shown is the first embodiment of the battery assembly for engineering vehicles of the present invention, the battery assembly for engineering vehicles of the present invention includes a battery main body 10, a hook portion 11, a limiting portion 12, a lifting support mechanism 20 and The rolling mechanism 30, the hooking part 11 is arranged at one end of the battery body 10, and is used to hook up with the external liftable push-pull mechanism 201 when replacing the battery, and push or pull the battery body 10; the limit The part 12 is arranged at the other end of the battery main body 10, and is used to position the battery main body 10 in the battery installation part 100 of the engineering vehicle. 101, the limit part 12 can ensure the stability of the battery main body 10 in the construction machinery, and prevent the battery main body 10 from moving in the engineering vehicle battery installation part 100 due to external factors such as road c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com