Bipolar plate for fuel cell

A fuel cell and bipolar plate technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve problems such as fluid inflow, closed inlet and outlet, and achieve the effect of ensuring balance and improving untimely supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

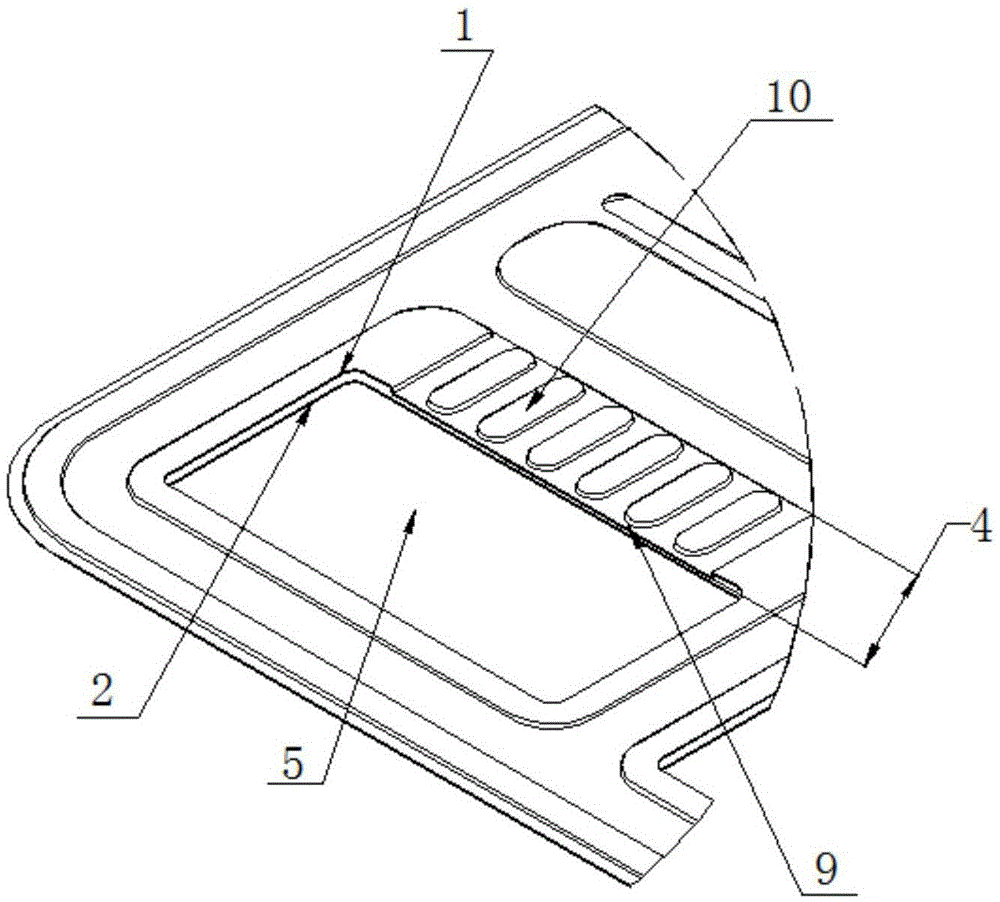

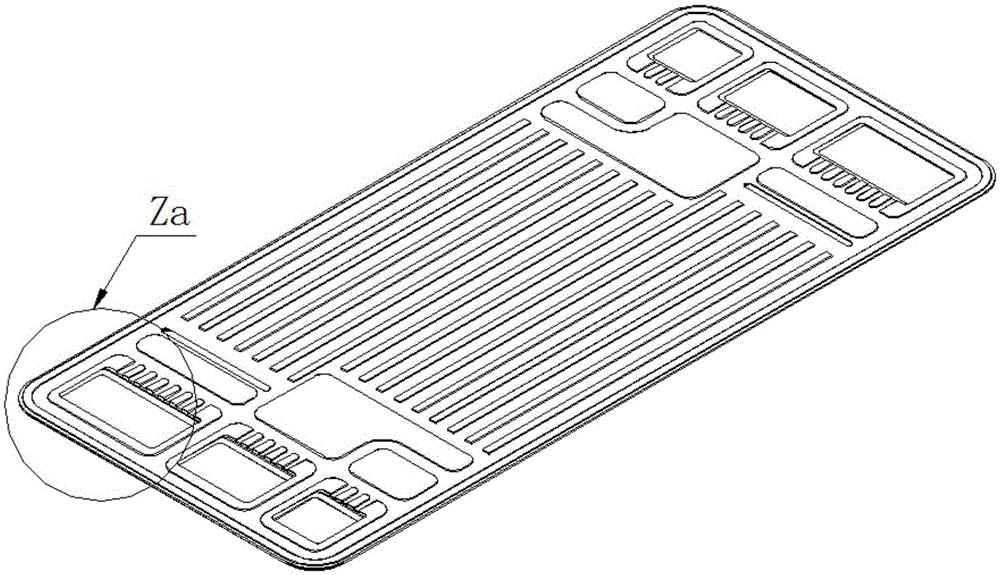

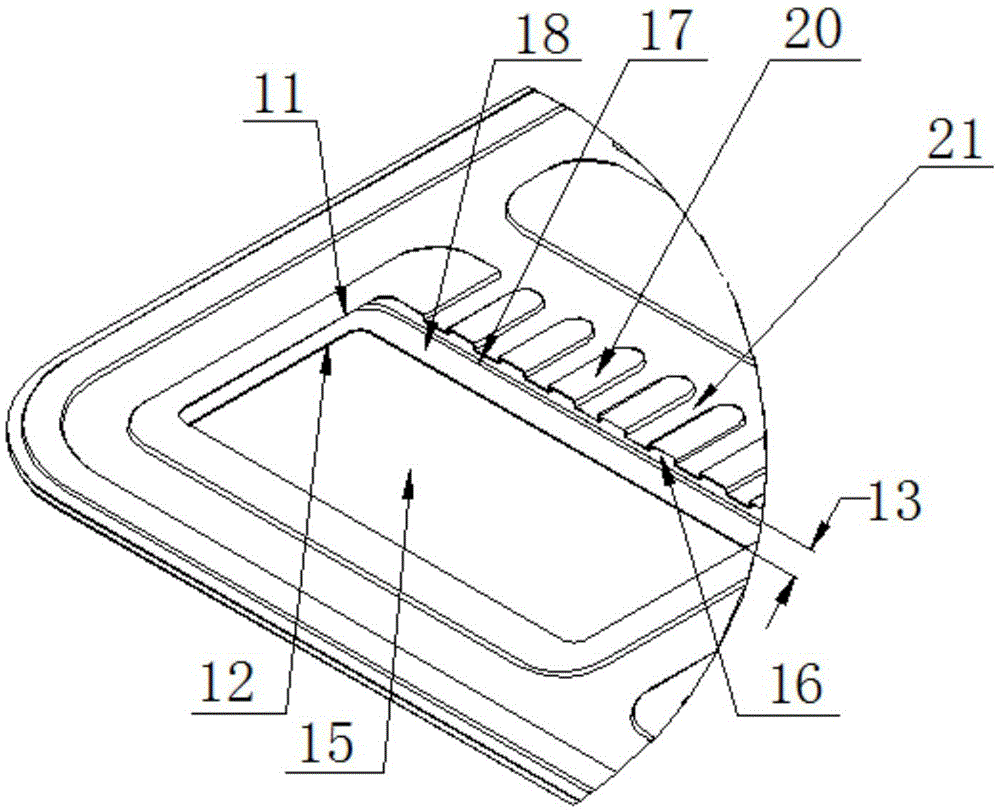

[0025] Such as figure 2 with image 3 As shown, it is a fuel cell bipolar plate provided in this embodiment, which includes a first plate 11, a second plate 12, and a manifold 15. The first electrode plate 11 is an anode hydrogen-conducting flow field plate, the second electrode plate 12 is a cathode air-conducting flow field plate, and a cooling fluid interlayer is formed between the first electrode plate 11 and the second electrode plate 12. The fluid inlet and outlet area of the first electrode plate 11 is provided with a plurality of diversion grooves 20 adjacent to the protrusions of the manifold 15. The second plate 12 includes an area 13 composed of a header pipe 17 and a header pipe 18. A plurality of protruding diversion grooves 20 are arranged at intervals, and a pressure-resistant connecting plate 21 is formed between every two adjacent diversion grooves 20. One end of each diversion groove 20 is set as a fluid inlet and outlet 16, and each diversion groove 20 Th...

Embodiment 2

[0032] Such as Figure 4 with Figure 5 As shown, it is a fuel cell bipolar plate provided by this embodiment, which is roughly the same as Embodiment 1, except that the projection line of the corresponding position of the second plate 12 is located in the fluid of the plurality of flow channels 20 The right side of the projection line of the longitudinal section defined by the inlet and outlet 16 is the side close to the flow field plate.

[0033] The design of the fuel cell bipolar plate, which is beneficial to the steady-state gas and water supply, can effectively reduce fuel loss and avoid water blocking. Improve fuel utilization and improve fuel cell efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com