Water-cooled screw type cold water unit

A technology for water-cooled units and chillers, applied in refrigerators, refrigeration components, compressors, etc., can solve problems such as unreasonable structural design, and achieve the effects of reasonable structural design, stable and reliable operation, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

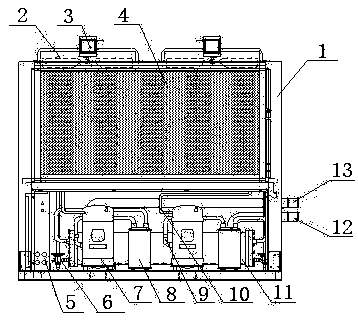

[0011] Such as figure 1 As shown, a water-cooled screw chiller, which includes a water-cooled unit shell 1, an axial fan 2, a motor 3, a finned heat exchanger 4, an electric control cabinet 5, an expansion valve 6, and a semi-hermetic screw compressor 7. Gas-liquid separator 8, low-pressure air return pipe 9, high-pressure exhaust pipe 10, shell-and-tube heat exchanger 11, chilled water inlet 12, and chilled water outlet 13. At least two An axial flow fan 2, the axial flow fan 2 is connected with the motor 3, the upper part of the water-cooling unit housing 1 is provided with a finned heat exchanger 4, and the finned heat exchanger 4 is opposite to the axial flow fan 2 Set, the lower side of the water-cooling unit shell 1 is provided with an electric control cabinet 5, and one side of the electric control cabinet 5 is provided with a semi-hermetic scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com