A motor control system

A motor control and control system technology, applied in the control system, AC motor control, electrical components, etc., to achieve the effects of improving system stability, simplifying circuits, and controlling flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

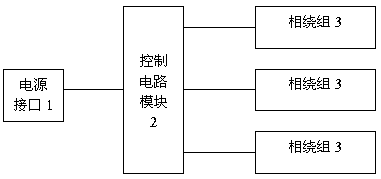

[0041] Embodiment 1: This embodiment provides a motor control system, the control system includes a power interface 1, a control circuit module 2 and a controlled motor;

[0042]The controlled motor includes more than three phase windings 3 that are not connected to each other (also known as windings, coil windings, for example, it is generally considered that a three-phase motor contains three phase windings 3; in some cases, one phase winding 3 is considered Contains one coil. In other cases, a phase winding 3 may contain multiple coils connected in series, or phase winding 3 is considered to be one or more parallel branches connected in series and in parallel according to regulations. a set of windings);

[0043] Each phase winding 3 is connected to the power supply through the sequentially connected control circuit module 2 and power supply interface 1;

[0044] The control circuit module 2 controls each phase winding 3 according to the combination of control parameters; ...

Embodiment 2

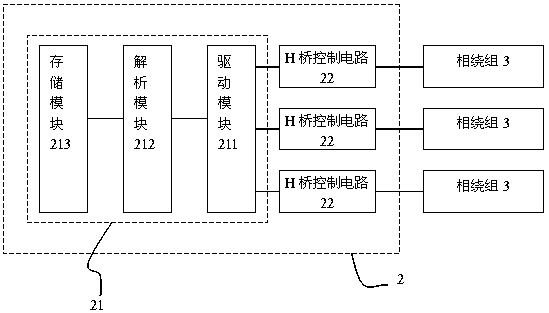

[0063] Embodiment 2: The difference from Embodiment 1 is that in this embodiment, as image 3 As shown, the control circuit module 2 includes a server, a controller 21 and an H-bridge control circuit 22 having the same number as the phase windings 3; the H-bridge control circuit 22 is connected to each phase winding 3 in a one-to-one correspondence; the controller 21 and Each H-bridge control circuit 22 is connected;

[0064] The server is provided with a remote storage module 231, and at least one control parameter combination of the controlled motor is stored in the remote storage module 231;

[0065] Such as image 3 As shown, the controller 21 includes a communication module 214, an analysis module 212 and a drive module 211, the communication module 214 is used to receive the control parameter combination from the server; the analysis module 212 combines the control parameters according to a specific algorithm It is parsed into a control command; the drive module 211 co...

Embodiment 3

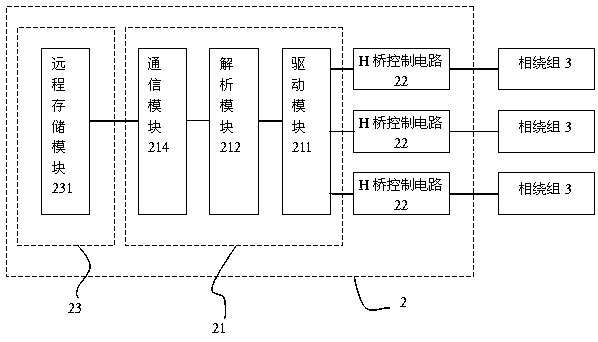

[0070] Embodiment 3: The difference from Embodiment 1 is that in this embodiment, as Figure 4 As shown, the control circuit module 2 includes a server, a controller 21 and an H-bridge control circuit 22 having the same number as the phase windings 3; the H-bridge control circuit 22 is connected to each phase winding 3 in a one-to-one correspondence; the controller 21 and Each H-bridge control circuit 22 is connected;

[0071] The server is provided with a remote storage module 231 and a remote analysis module 232, and at least one control parameter combination of the controlled motor is stored in the remote storage module 231; the remote analysis module 232 analyzes the control parameter combination into a control instruction according to a specific algorithm ;

[0072] Such as Figure 4 As shown, the controller 21 includes a communication module 214 and a driving module 211, the communication module 214 is used to receive the control parameter combination instruction from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com