Tool holding fixture

A tool holder and tool technology, which is used in the attachment of tool holders, tools for lathes, shrink connections, etc., to achieve the effects of rapid speed change, increased productivity, and less energy input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

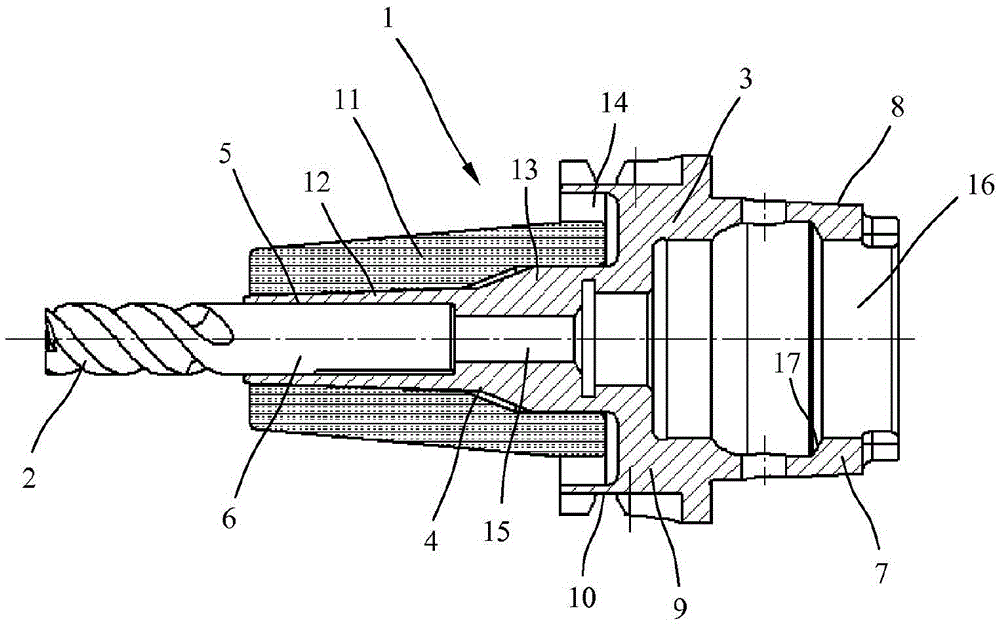

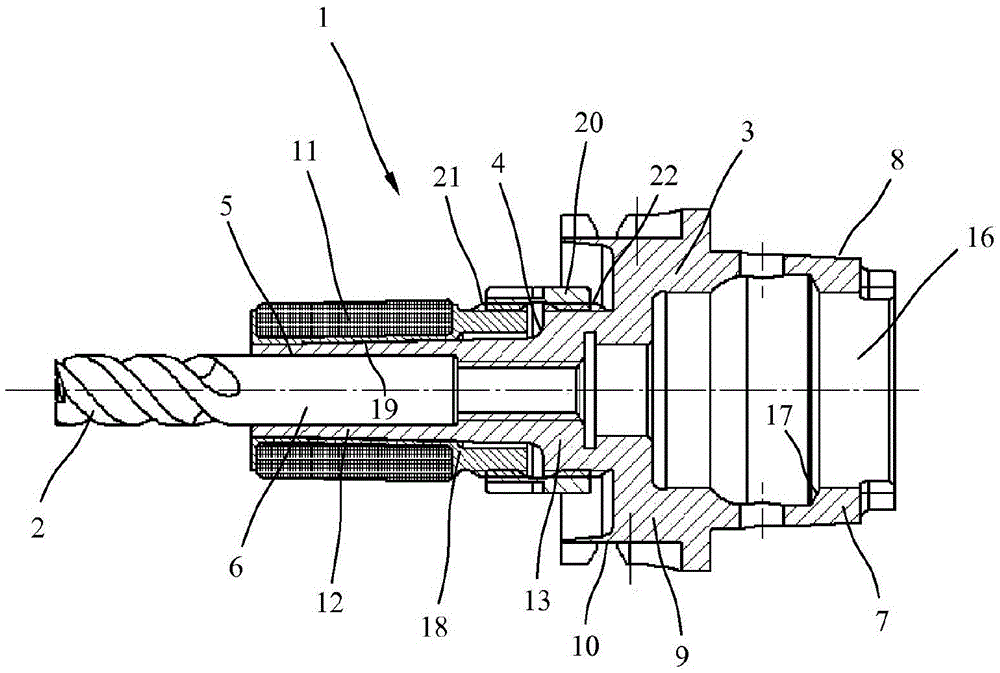

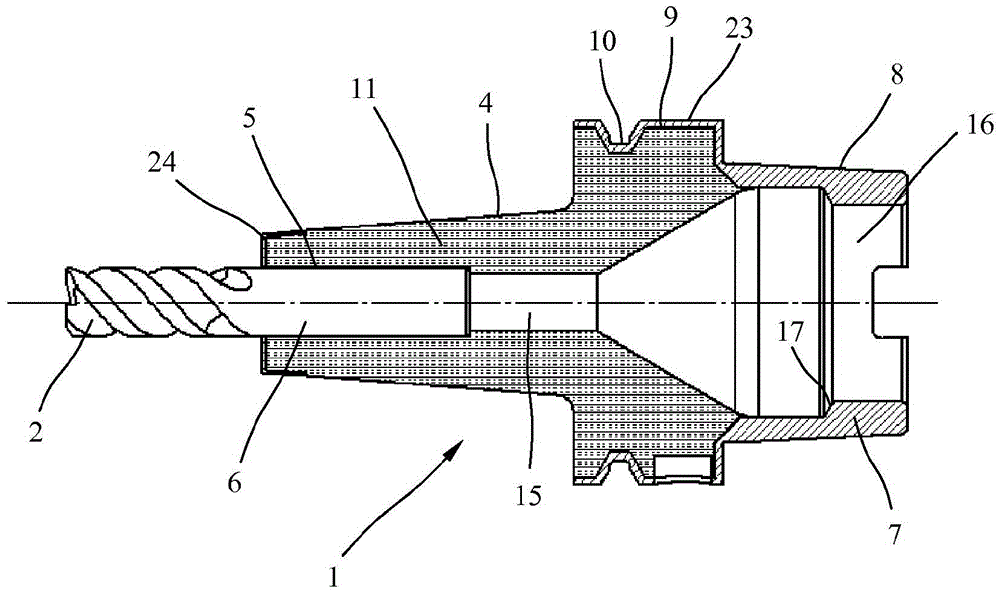

[0032] exist figure 1shows a tool holder 1 here with an HSK interface for non-positive clamping of drills, milling cutters, grinding tools or other rotary-driven tools 2 . The tool holder 1 is formed in the exemplary embodiment shown as a thermotechnical clamping chuck and comprises a rotationally symmetrical receptacle 3 , which has a receiving opening with a shank 6 for the tool 2 at its tool-side front end. 5 and, at its machine-side rear end, a conical rear receiving region 7 with a conical outer clamping surface 8 here for receiving in the machine tool work spindle. The steel receiving body 3 also has a cylindrical central region 9 with a grip groove 10 for engaging a tool changer. A sleeve 11 made of carbon fiber-reinforced plastic (CFK) or another fiber-reinforced plastic is arranged on the front clamping region 4 of the receiving body 3 .

[0033] exist figure 1 In the exemplary embodiment shown, the sleeve 11 made of CFK is arranged with a force fit / interference fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com