Multilayer film comprising biopolymers

A multi-layer film, polymer technology, applied in the direction of packaging items, special packaging items, synthetic resin layered products, etc., can solve problems such as plasticizer migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0230] Example 1: Preparation of a multilayer film according to an embodiment of the present invention

[0231] A pre-compound comprising:

[0232] 65% by weight NatureWorks PLA4060D, which is a commercially available amorphous PLA

[0233] resin.

[0234] 30% PBAT, and

[0235] 5% black MB which is a commercial black pigment in PLA provided as a masterbatch.

[0236] This compound was used as layer A in the coextruder. Layer B is 100% PBAT. Using from BASF FBlendC1200 as PBAT. Extruder A for layer A was heated from 140°C to 220°C while extruder B for layer B was heated from 120°C to 200°C. Coextruded layers A / B (100 μm / 100 μm) were calendered between two rolls at 20-60° C. to give layer A a glossy appearance.

Embodiment 2

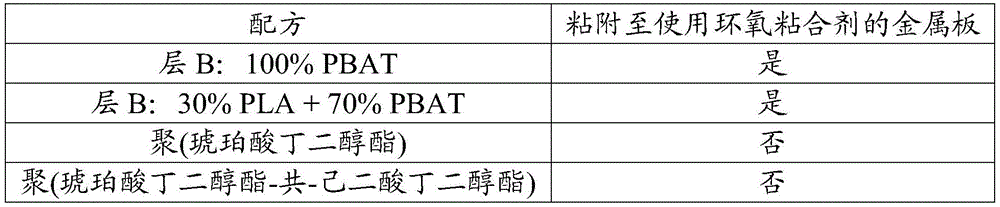

[0238] Adhesion of Layer B to the metal plate was evaluated using a two rubber roll calender. The adhesion properties were compared with other types of polymers. The results are shown in Table 1. Using from BASF FBlendC1200 as PBAT. As PLA, NatureWorks PLA4060D, which is a commercially available amorphous PLA resin, was used.

[0239] Adhesion was tested using the following procedure: After glue activation at 200-240°C, the glued metal was pressed onto the multilayer film under two rubber rollers and rapidly cooled in a water bath. Use a knife to create only scratches with the following cross-hatched shape # on the film layer. High-speed embossing is performed on the scratched area. Adhesion was then assessed by manually attempting to remove the film from the metal with a knife.

[0240] Table 1.

[0241]

[0242]

Embodiment 3

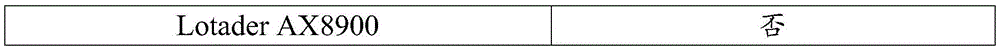

[0243]Example 3: Preparation of Multilayer Films According to the Invention and Comparative Examples

[0244] Different combinations of layers A and B were coextruded to confirm the level of adhesion between these two layers. The compositions and results are shown in Table 2. Using from BASF FBlendC1200 as PBAT. As PLA, NatureWorks PLA4060D, which is a commercially available amorphous PLA resin, was used.

[0245] When a mixture is used, the pre-compound is extruded on a twin screw at a temperature in the range of 140-220°C. This compound was used as layer A in the coextruder. Use the same procedure for layer B. The co-extruder was heated from 140 to 220°C, while extruder B for layer B was heated from 120 to 220°C. Coextruded layers A / B (100 μm / 100 μm) were calendered between two rolls at 20-60° C. to give layer A a glossy appearance.

[0246] Table 2. Coextrusion results.

[0247]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com