Gas turbine and heat shield for a gas turbine

A technology for gas turbines and heat shields, applied in the direction of machines/engines, mechanical equipment, engine functions, etc., can solve problems such as gas turbine efficiency loss, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

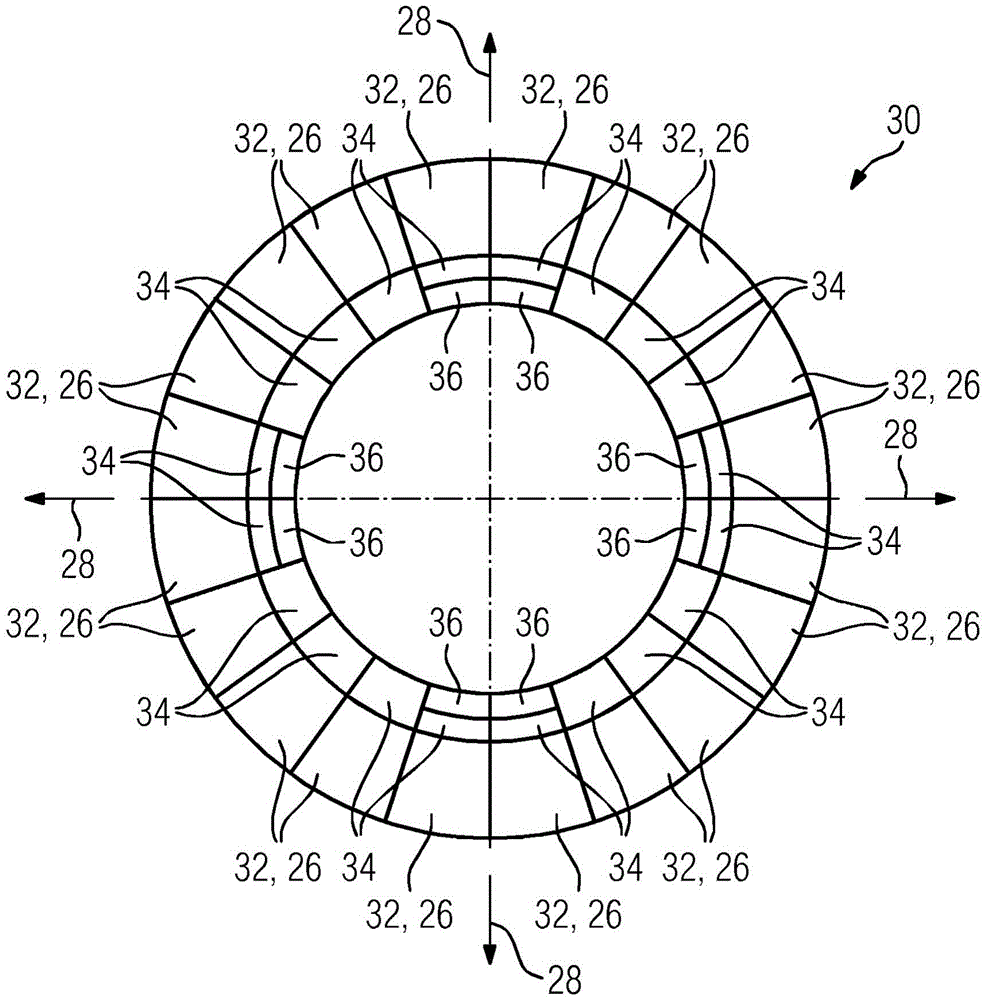

[0022] Mutually corresponding parts are indicated by the same reference numerals throughout the figures.

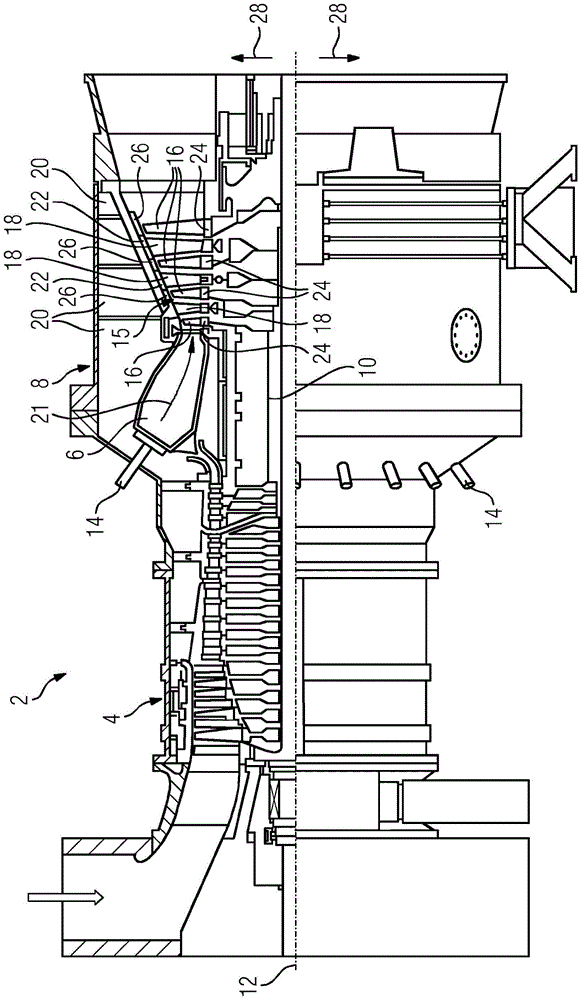

[0023] The gas turbine 2 described below by way of example is figure 1 Shown in , and in a manner known per se, is a compressor 4 , a combustion chamber 6 and a turbine unit 8 .

[0024] The combustion chamber 6 , formed in the form of an annular combustion chamber, is in this case equipped with several burners 14 for the combustion of liquid or gaseous fuels and opens into the hot gas duct 15 of the turbine unit 8 .

[0025]The turbine unit 8 and the compressor 4 are further arranged on a common turbine rod 10, also called a turbine rotor, to which a working machine (not shown) is also connected in a non-deterministic locking manner, and the turbine rod 10 is mounted It is made rotatable about the turbine shaft 12 . Further, the turbine unit 8 has a plurality of rotor blades 16 arranged in the hot gas duct 15 and connected to the turbine shaft 10 and rotatably mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com