Control valves for retrofitting on internal combustion engines

A technology for controlling valves and internal combustion engines, applied in engine control, internal combustion piston engines, combustion engines, etc., can solve the problems of complicated manufacturing and assembly of valves and heat shields, and achieve good heat shielding, low weight, and low assembly costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

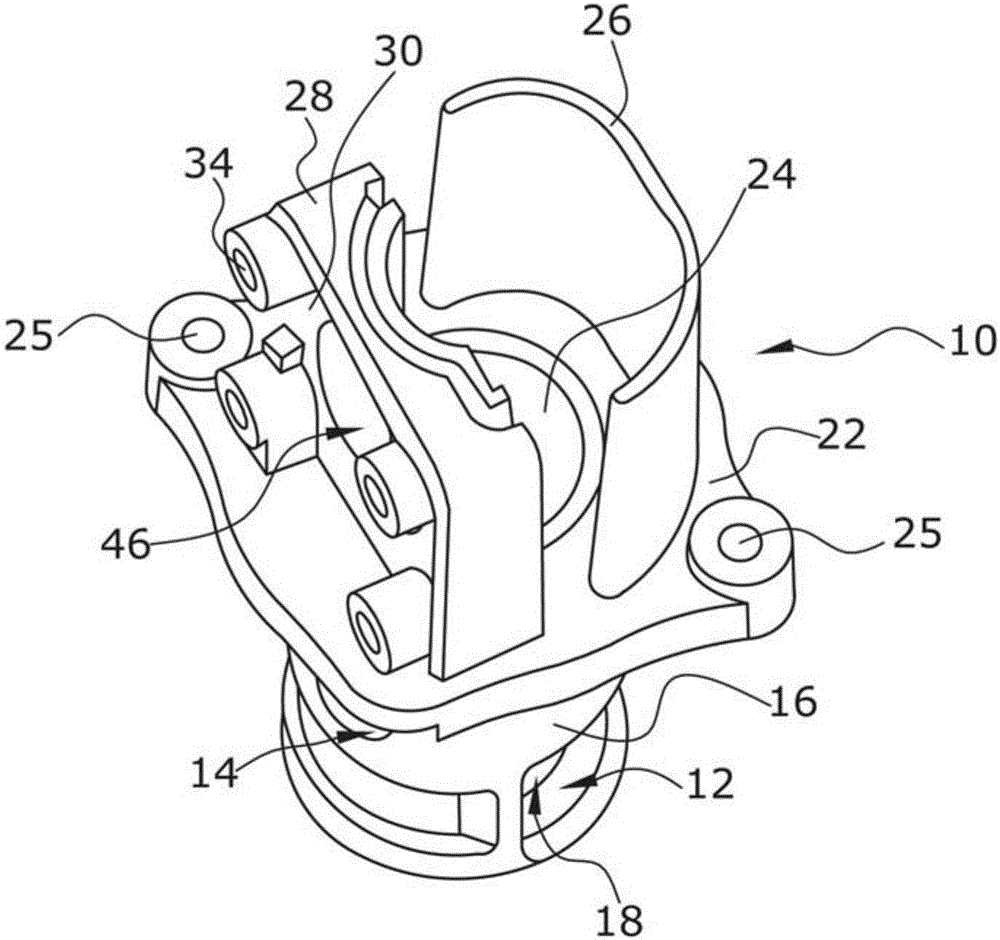

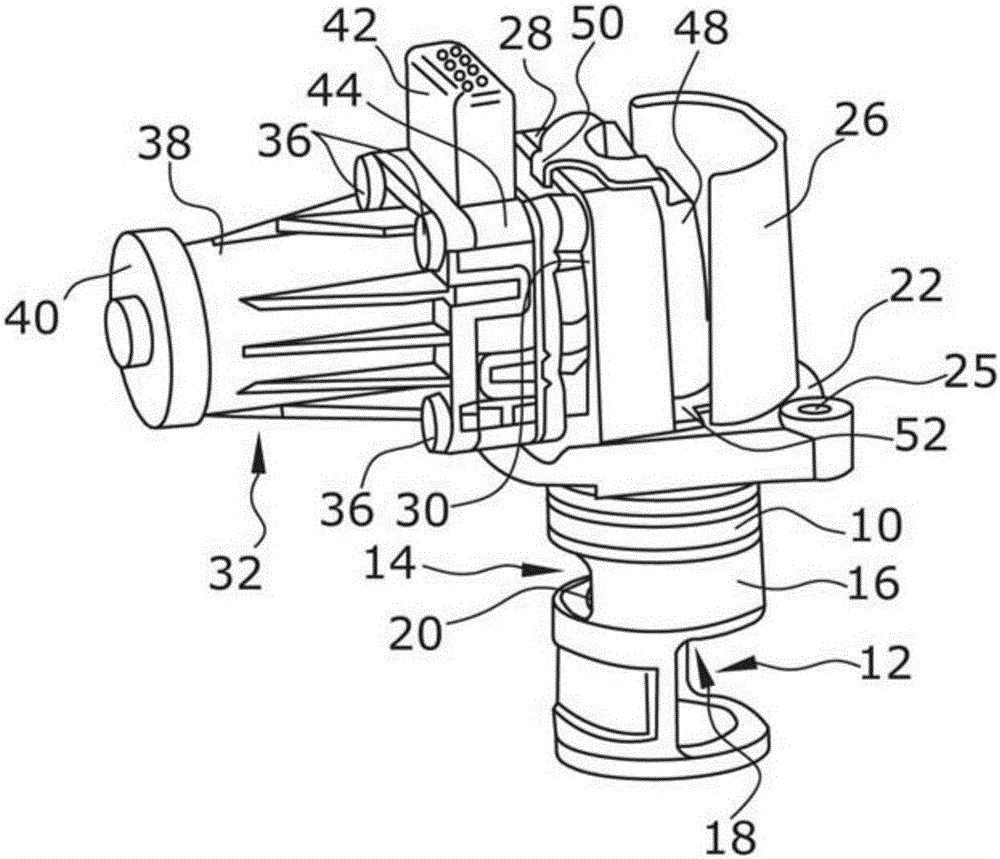

[0023] The control valve according to the invention has figure 1 Housing 10 is shown, which is produced from lightweight metal by die-casting. The control valve is designed as a plug valve, so that the inlet 12 and the outlet 14 are arranged on a cylindrical base body 16 so that they overlap one another. Between the two windows forming the inlet 12 and the outlet 14, a channel 18 is formed on the base body 16, which is surrounded by a valve seat 20 and is used as a valve closing body, not shown in the drawing, as a control body. It can be seated on the valve seat 20 in the closed state of the channel 18 , and the valve closing or control body can be lifted from the valve seat 20 in the control state.

[0024] The control body is fastened to the likewise invisible operating mechanism in the form of a valve stem. The valve stem extends along the central axis of the base body 16 and protrudes through a flange 22 which delimits the base body 16 and has a flange opening 24 for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com