Chafing dish provided with lifting filtering tray

A technology for trays and hot pots, which is applied to the structure of cooking utensils, multi-unit cooking utensils, inserts, etc., can solve the problems of inconvenient selection and easy to stick to the bottom, so as to prevent the bottom from sticking, prevent scalding, and prevent excessive boiling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

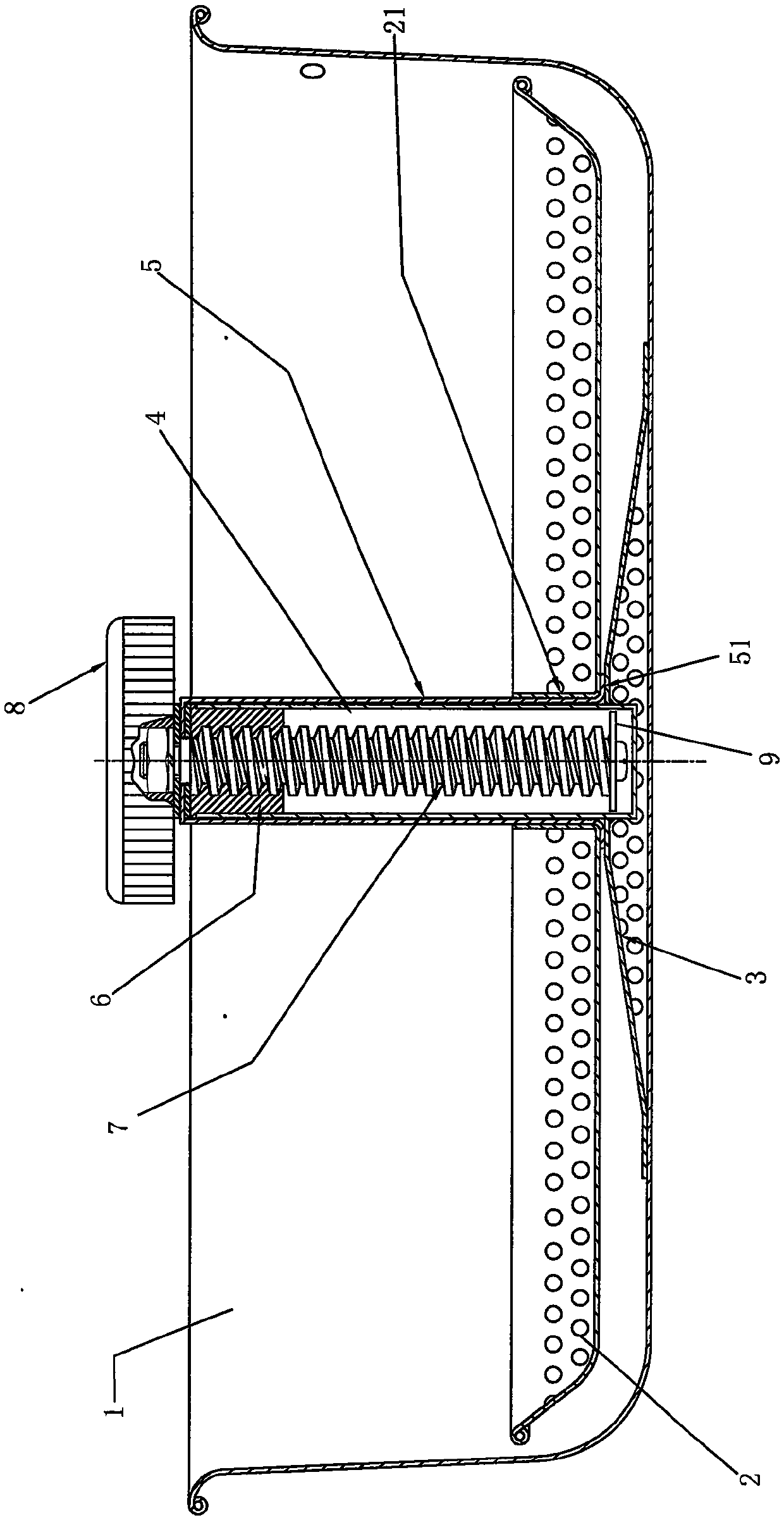

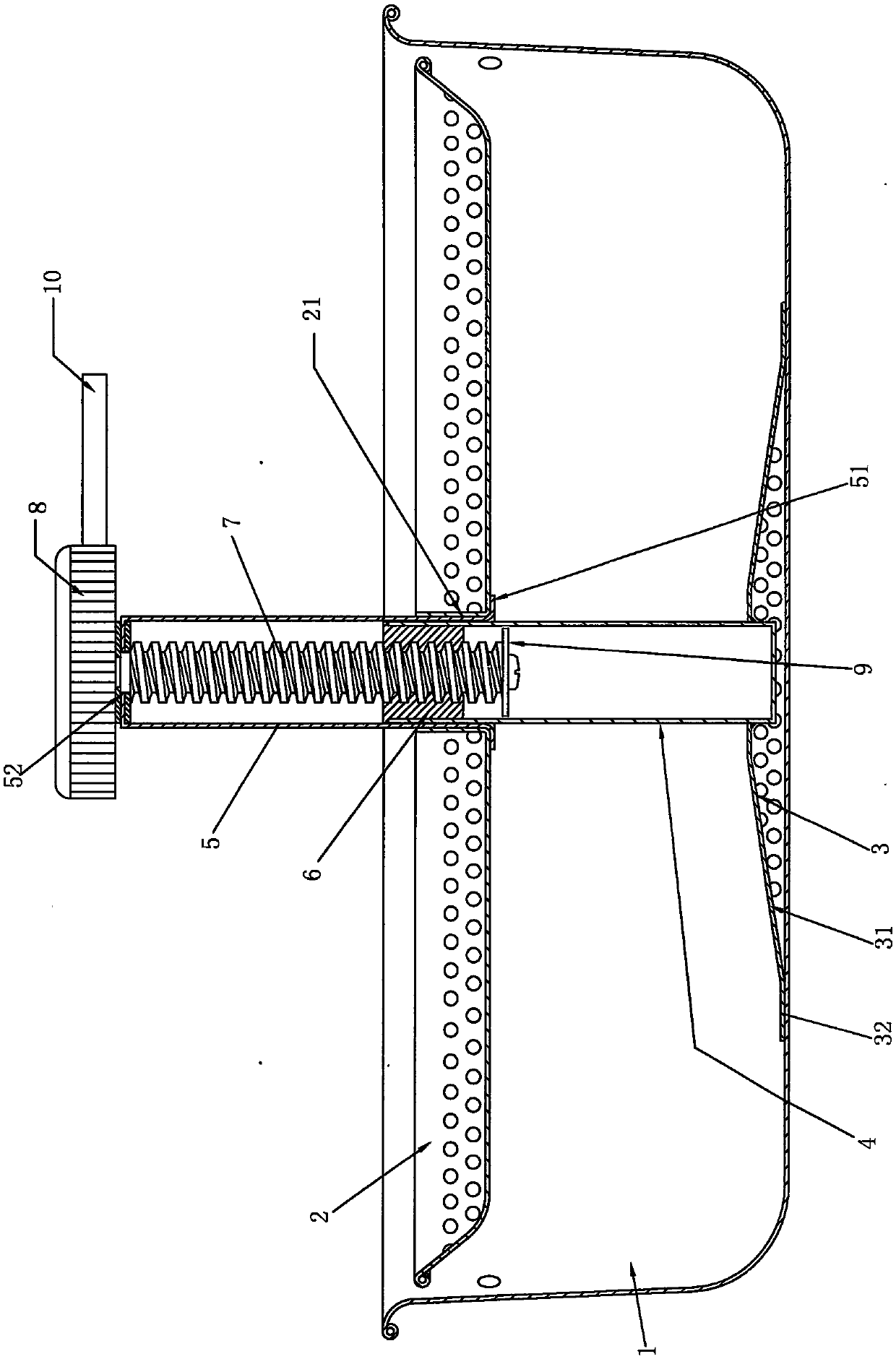

[0036] Such as figure 1 As shown, a hot pot with lifting filter tray includes a hot pot body 1 and also includes a filter tray 2 and a lifting mechanism, and the diameter of the filter tray 2 is smaller than the diameter of the hot pot body 1;

[0037] The lifting mechanism is supported and matched with the bottom plate of the chafing dish body 1, and the filter tray 2 is detachably connected or fixedly connected with the lifting mechanism.

[0038] The center of the filter tray 2 has a guide sleeve 21;

[0039] The lifting mechanism includes a support base 3, a support inner sleeve 4 with a closed lower end, a sliding support outer sleeve 5, a nut 6, a screw rod 7 and a knob 8,

[0040] The lower end of the sliding support outer sleeve 5 is open and the lower end is provided with a circular support plate 51, and the top end plate of the upper end has a pivot hole 52;

[0041] One end of the screw rod 7 is a driving end, and the other end is a floating end;

[0042] The sup...

Embodiment 2

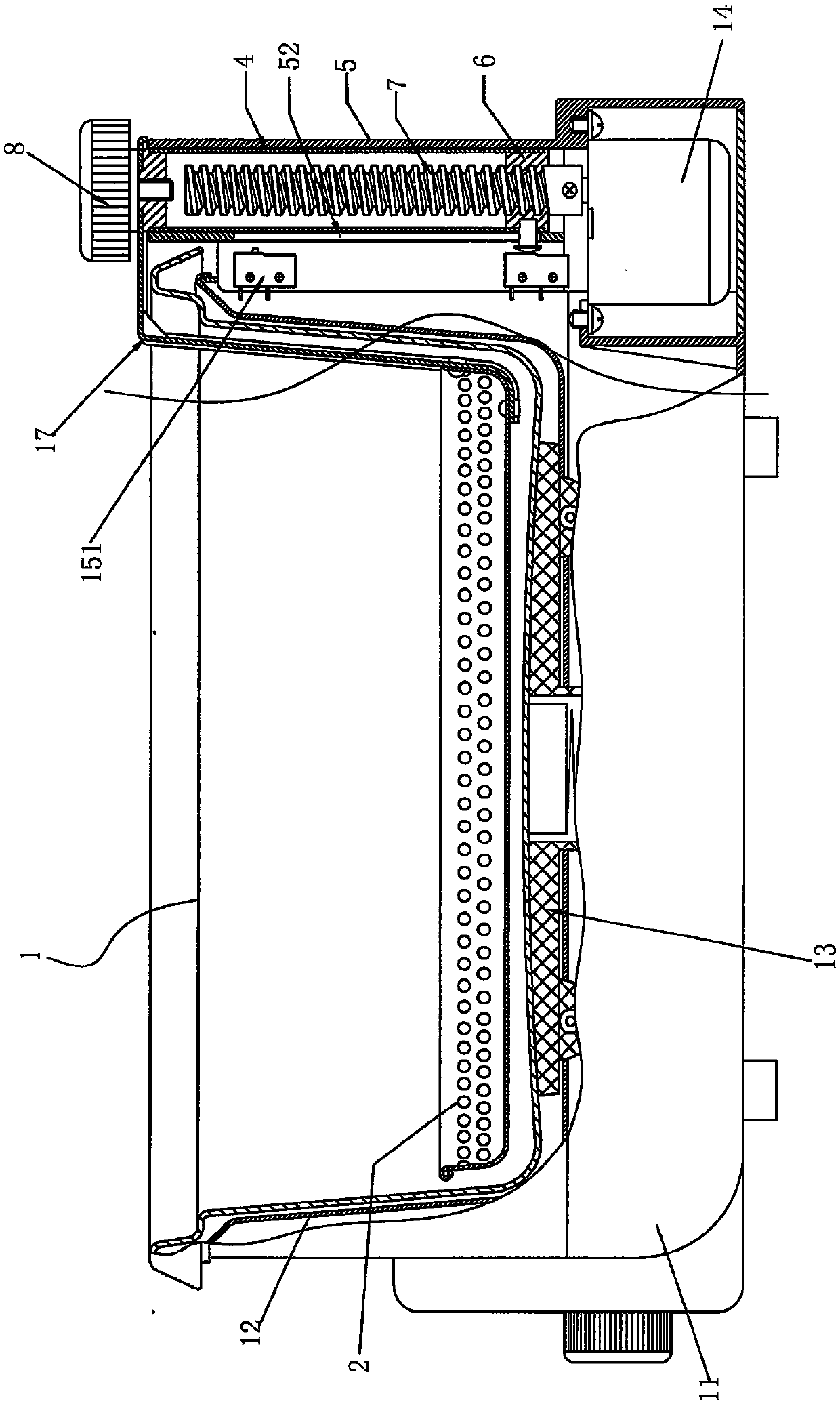

[0056] Such as image 3 , Figure 4 Shown, a kind of chafing dish with lifting filter tray comprises base 11, jacket 12, electric heating plate 13 and chafing dish body 1, and jacket is arranged on the base, and chafing dish body 1 cooperates with jacket.

[0057] It also includes a filter tray 2 and a lifting mechanism, the diameter of the filter tray 2 is smaller than the diameter of the chafing dish body 1;

[0058] The lifting mechanism is supported and matched with the base 11, and the filter tray 2 is connected with the lifting mechanism.

[0059] The lifting mechanism includes the supporting inner casing 4, the supporting outer casing 5, the nut 6, the screw 7, the motor 14, the upper stroke switch 151, the lower stroke switch 152, and the anti-rotation pin body 16;

[0060] The tube wall of the supporting outer sleeve 5 has a guide hole 52 along the height direction of the supporting outer sleeve; the lower end of the supporting outer sleeve 5 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com